Your Guide To ABS Injection Molding

Thermoplastics are the most common materials used in injection molding processes. ABS is a rigid and tough thermoplastic material used to produce several plastic parts for common and industrial use. The properties of the material give the parts increased tensile strength and durability. Moreover, plastic is relatively inexpensive, leading to lower production costs. Learn all about the ABS injection molding process through this blog.

What Are ABS Plastics?

Acrylonitrile Butadiene Styrene (ABS) is an amorphous form of thermoplastic. The acrylonitrile gives the plastic higher heat and chemical resistance. The butadiene gives the plastic impact resistance and durability, and the styrene increases its ability to be molded easily.

Since ABS is amorphous, it has no true melting point and does not burn when heated. This further makes it easier to be molded. ABS plastic is commonly used in consumer goods, electronic components, and industrial machinery. But it’s commonly used in places where it doesn’t come into contact with direct sunlight.

ABS Processing Concerns

Viscosity

The melt temperature determines the plastic’s viscosity. Viscosity is the fluid’s resistance to flow, and a higher viscosity will lead to lower flow rates and, in some cases, product wastage. ABS plastics generally have a higher viscosity. That’s why they’re melted at a higher temperature than required. ABS plastics behave differently from other amorphous plastics and are difficult to mold.

Moisture Absorption

ABS plastics are prone to absorbing moisture during processing. Proper drying is needed before the melting process; otherwise, the melt will absorb all the moisture in the processing materials and equipment. This increases the operating cost and lead times. In some cases, moisture still gets in the molten plastic and causes cloudiness and chemical degradation. The moisture levels should be kept below 0.4% by drying it at temperatures between 80 to 90 degrees Celsius. Usually, the drying process takes around 4 hours.

Temperature

Because of the viscosity concerns, ABS plastics are overheated, which also causes thermal decomposition in the melts. Thermal decomposition breaks down the chemical bonds and introduces brown granules in the molded product. The temperature should be carefully monitored to prevent any of these issues. Moreover, the mold temperature is kept higher than the melt temperature to ensure the temperature changes don’t cause chemical degradation.

Injection Pressure and Speed

Because of the high viscosity, higher injection pressures are required to maintain the flow rate. But if the pressure is too high, it’ll cause the molded parts to stick, which can cause issues during ejection and can waste material. Similarly, lower pressures can lead to shrinkage in the mold. Injection speed is also quite important. The plastic might thermally decompose or burn if the melt is injected at higher speeds. It can also introduce weld lines or burn marks. Lesser shot size is required to improve dimensional stability.

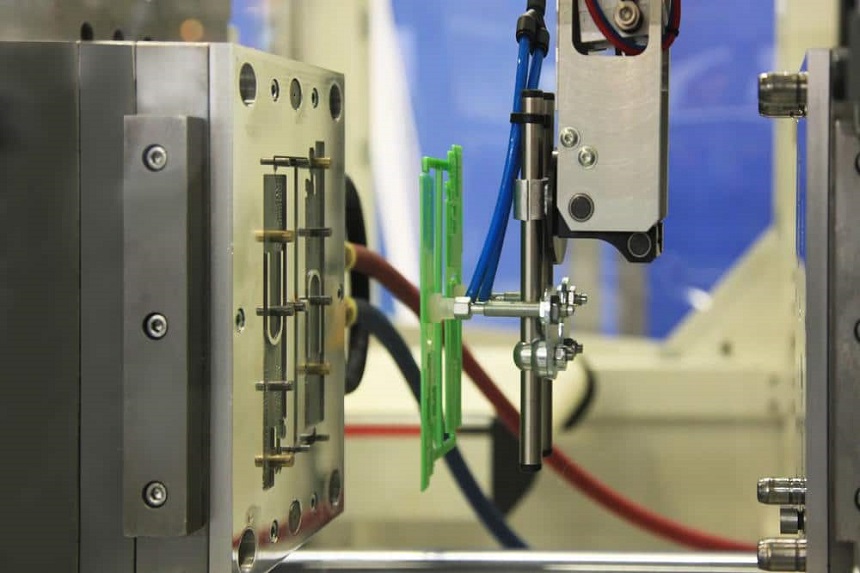

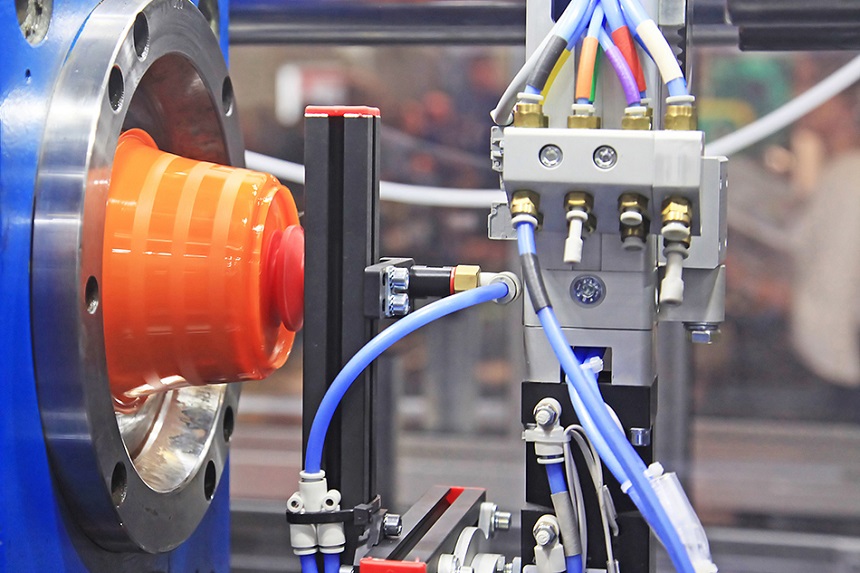

Abs Injection Molding Process

The Abs injection molding starts by melting the pellets at a temperature between 180 to 280 °C. For heat-resistant pellets, the temperature can be even higher. After melting, the resin is passed through the nozzle to the mold. The nozzle temperature is kept between 180 to 220 °C. This maintains the flow rate of the melt before going into the mold.

During injection, the pressure is maintained between 60 to 150 MPa. If thicker walls are required, higher pressure is needed, but it should be noted that high pressures should be properly regulated to prevent internal stress in the melt. Before the injection, the injection mold temperature should be kept at around 40 to 80 °C. This minimizes internal stress in the melt and prevents shrinkage of the product. Because of its higher viscosity, ABS plastic takes a longer setting time.

Advantages Of Using ABS Plastic in Injection Molding

Good Coloring Options

Raw ABS has an opaque ivory color, making it easier to adhere to different color pigments. The colors also have good radiance and homogeneity. Besides that, ABS is also good for metal coating without conducting electricity. Certain parts need specific coloring to meet industry regulations, so ABS plastics are also good for that.

Post Processing

Despite being sturdy and hard, ABS plastic maintains flexibility after plastic injection molding. It helps post-processing if the finished parts require drilling before being used or require parts to be sawed off. Other plastics might develop cracks or break completely in such circumstances.

Resistant To Chemicals

Finished ABS products resist chemical degradation from water, gasoline, alcohol, and even acetone. As a result, it makes it easier to use plastic in a wide range of applications, such as in engine parts and water-proof electronics.

Dimensional Stability and Abrasion Resistance

Shrinkage is common in plastics after injection molding. This can cause dimension changes and, in certain cases, product deformation. However, with ABS plastics, the shrinkage value is only around 0.8% compared to 6% in other plastics. This allows the finished products to hold their shape for a longer time. ABS also has good abrasion resistance making it a good option for glossier finished parts such as toys and electronics.

Recycle Options

ABS is one of the few resins that can handle multiple reheating cycles and can handle moderate to high recycled content. Besides that, during the injection molding process, some amount of material is wasted as scrap material and waste from the runners. This wasted material can go into a re-grinder, where it can be mixed with fresh ABS melt to reduce production waste. In the long run, this leads to significant cost savings.

Find Quality ABS Injection Molding Services With PTMS

PTMS is one of the top injection molding companies in China. We offer mass production of plastic products at an affordable rate due to our skilled labor and top-notch machinery. Our injection molding company has been around since 2002 and is also ISO9001-2008 certified. We use high-quality resin to create products that are functional and durable.

Our other services include mold design, plastic injection tooling, and product assembly. Most of our products are exported to the US, Japan, Europe, and Australia. We believe in going above and beyond for our customers to give them the best services and products. You can learn more about our range of services by browsing our website or getting in touch with us.