Benefits of Injection Molding for Your Plastic Products

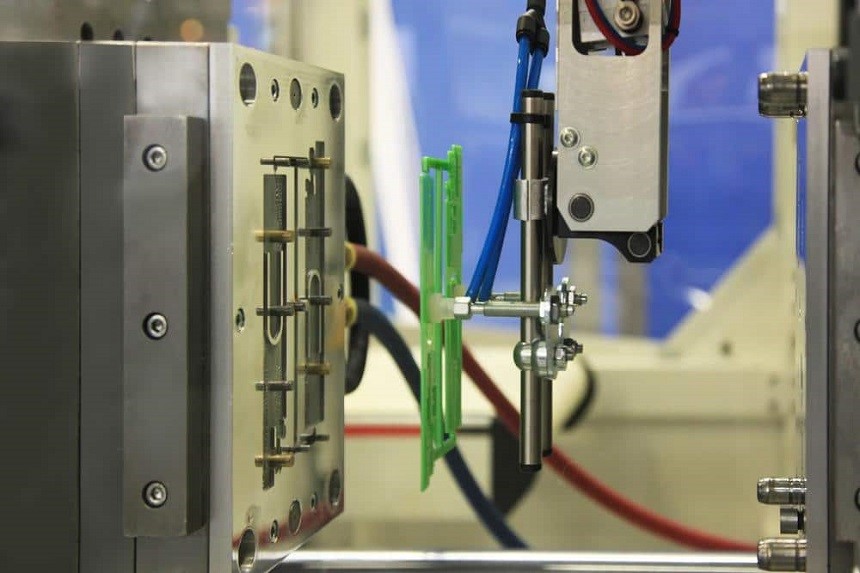

The molten plastic is injected into a mold cavity during plastic injection molding, which produces the final products by hardening the mold. This is one of the most common and affordable manufacturing processes. This process is efficient and reliable enough to meet your specifications and needs.

Let’s look at some benefits of injection molding for your plastic parts:

Fastermass production

Computer-Aided Manufacturing (CAM) and Computer-Aided Design (CAD) are used to design injection molds. The designs are created as per the customer’s specifications.

Once the preparation of mold is done, the actual production process is pretty fast. Compared to traditional methods of molding, injection molding is very quick, especially for mass production.

The plastic injection molding process saves a lot of time and helps produce parts in bulk – this is done through a single mold, which creates a high production output rate.

Accuracy with complex designs

Thanks to the techniques that injection molding uses, creating complex designs and adding many details to the parts isn’t difficult anymore. Due to the use of high pressure, pressing the plastics harder is possible, which helps create intricate designs.

This way, you can precisely create complex design features within plastic parts – something which wasn’t possible with molding machines of the past. In fact, any type of plastic can be fabricated to a precision level within 0.001 inches.

In addition, the process is entirely automated, allowing you to manufacture some of the most complex parts without spending a lot.

Design flexibility

The ability to be flexible in designs is one of the main reasons plastic injection molding is so popular. If you’re someone who needs plastic parts, you’ll be impressed with the amount of flexibility injection molding can offer.

The ability to be flexible with respect to color choices, create accurate designs, and choose a variety of plastics is possible with injection molding. This means you can create whatever design you want to, which was impossible to do with traditional molding processes.

PTMS offers custom plastic injection molding using 100% brand new materials.

With years of experience in plastic injection molding, PTMS has been offering customers top-of-the-line custom plastic injection molding for almost two decades.

Get in touch with us now to get an injection molding quote!