How Does Plastic Injection Molding Help The Medical Industry?

The process of plastic injection molding has been around for quite some time and is used to produce everything from toys to parts of machines. injection molding is quick, easy, and can be done on a massive scale. This means that it’s often the method of choice when manufacturing new products or updating old ones. Because this process produces such consistent results, it’s ideal for creating medical devices as well.

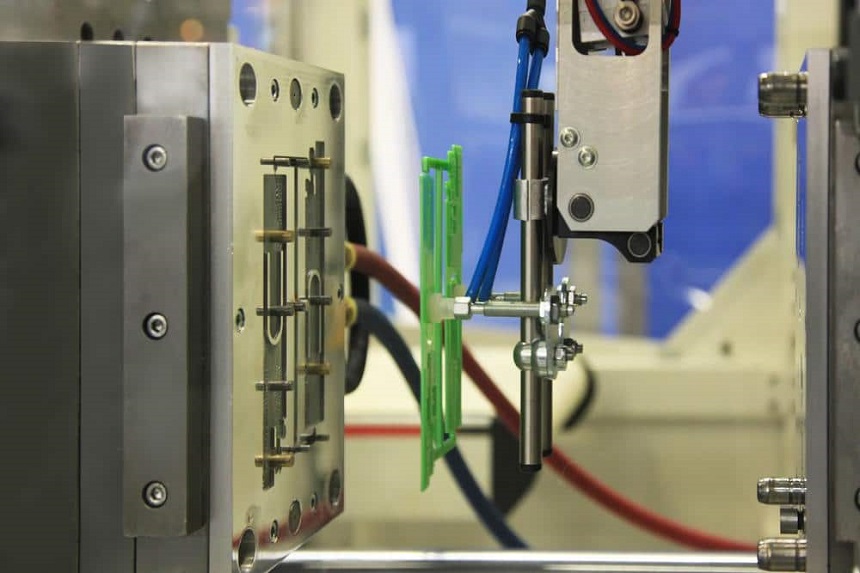

Plastic injection molding for medical devices

Plastic Injection has recently received increased interest as the demand for reusable medical devices that are more environmentally friendly continues to rise. The FDA has also played a vital role in the increased use of plastic injection molding by publishing draft guidance on the subject aimed at manufacturers who design and develop their own devices.

Many medical devices are now made from plastic, including stents and implantable rods.

The most effective method of creating medical devices is plastic injection molding. This process involves using a metal die to create the desired shape in thick sheet steel. The sheet steel is then heated, injected with molten plastic, and allowed to cool before being ejected from the mold.

This method can produce thousands or even millions of identical pieces simultaneously, making it an effective solution for mass production. It also means that it can be used to create prototype for rapid prototyping, significantly reducing the upfront cost of creating a finished product.

Although this method requires an initial investment in machinery, it allows for versatility and ease of use when producing medical devices.

Types of Injection Molding used in Medical Device Technology

Types of injection molding used in medical device technology are

-Cold injection molding

-Hot-runner system

-Gas assist.

Cold injection molding is the old method for making small to medium-sized parts with low part cost. Typical applications include more than one material, short runs, fast design changes, and prototypes. The primary concerns of cold molding are the physical properties of the plastics used and the design for manufacturability.

Hot-runner systems use hot plastic to fill cavities with cold runners. This is expensive but has high repeatability, reasonable dimensional control, and a good surface finish. Typical applications include medium-sized parts with complex geometry or many cavities, no part changes, and high-volume production. The primary concerns of hot-runner systems are assembly costs, the number of cavities per part, cycle times, and rigidity of the mold.

Gas assist technology is an excellent method for large parts with many cavities or complex geometry. It is ideal for high-volume production. Gas assist technology uses gas pressure to push the plastic resin into the cavities of a mold. The primary concerns of gas-assist injection molding are cycle time, mold rigidity, and part cost.

The injection machines of PTMS can run every type of resin – from high temperature to filled materials, commodity to grades. We only work with high-quality plastic resin suppliers within the industry. As one of the leading injection molding companies, the plastic resin we use is 100% qualified.

We’re an ISO 9001-2008 company and are extremely strict with the product quality.

Contact us now for more information on our plastic injection molding service!