Understanding Injection Molding Cooling Times

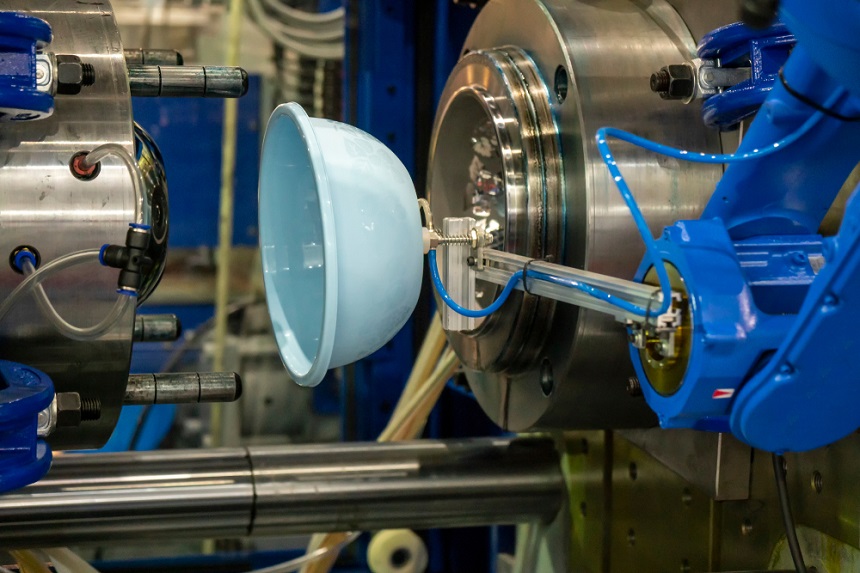

In plastic injection molding, the cooling time is one factor that substantially affects the overall quality of a product. Generally, a shorter cooling time signifies an optimized injection mold cooling system and greater output (in the long run).

Here, we briefly discuss injection molding cooling times.

How to calculate cooling time in plastic injection molding?

To calculate cooling time, use an equation that incorporates wall thickness and thermal diffusivity (a measurement that quantifies the plastic’s density, thermal conductivity, and energy requirements to raise its temperature). The estimated time also depends on the type of thermoplastic, as every thermoplastic has different molding and melting temperatures. While this equation is a tad complex, if you’re working with an experienced injection mold maker like PTMS, don’t worry, as we’re well-versed in this process.

Although this may take most of the cycle time, rushing cooling time in plastic injection molding is never recommended. It takes a combination of accurate mathematics, mold design, and patient to generate a cooling time that will result in maximized manufacturing speed. At PTMS, we excel at designing prototypes and executing production, which results in efficient lead times.

Why is cooling time important?

If cooling isn’t executed properly, the plastic part won’t harden sufficiently, leading to damage from the firing ejector pins. Even the design of a mold can influence the cooling process, resulting in delamination, warping, discoloration, sinking, and shrinking. If cooling channels are implemented into the mold’s design, it can lower the temperature of the cavity wall and aid in the dispersal of heat, which in turn results in even cooling.

But excessive cooling isn’t recommended either as it may increase the cycle time unnecessarily, which is why it’s important for molding manufacturers to precisely estimate cooling time.

What factors affect the cooling process?

To melt plastic resin, an incredibly high temperature is needed. As a result of this immense heat, the cooling process may take up to 4/5th of the cycle time. Following factors of the plastic injection molding are the temperature changing phases, which lead up to the final product:

- Cooling state: This process begins once the material in the mold is packed and held. During this phase, the plastic takes on the permanent shape of the mold as it solidifies.

- Mold packing and holding: Some of the plastic begins to cool and shrink as the injection continues. To ensure the cavity is filled, more material is injected and held to ensure no backflow occurs.

- Heating and injection: To liquify base resin, it’s subjected to high temperatures. Once it’s melted to the right viscosity, it’s injected into the mold.

Once this process is complete, the part is taken out of the mold and inspected for quality assurance. If cooling time isn’t calculated properly, it may lead to defects.

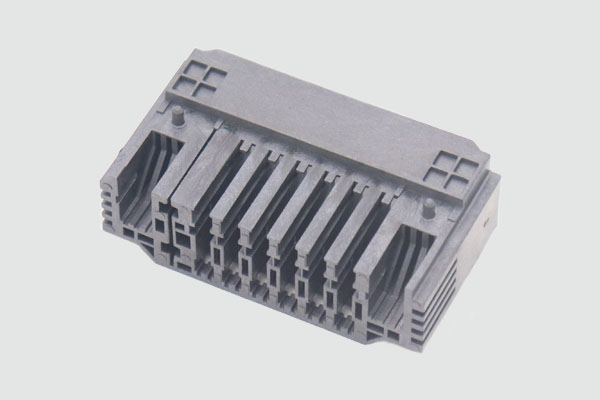

PTMS offers a top-quality plastic injection molding service.

Over the past 2 decades, PTMS has accumulated rich experience in producing a number of different plastic injection molded parts. In addition, we can also make other special customized parts if possible.

Give us a call now for an instant injection molding quote!