Benefits of Replacing Metal Parts with Plastic

Manufacturers have relied on metals due to the abundance of favorable qualities they possess. Metals are stiff, strong, and have ideal characteristics related to electricity and chemical resistance. However, the need for reducing operational costs, complex designs, and fast-paced production is greater than ever. Plastics, fortunately, have some similar characteristics as metals and are their cost-efficient alternatives. While metal-to-plastic conversion was introduced in the 1950s, most manufacturers are not familiar with the benefits of metal replacement with plastic parts.

Here, we highlight some of the main ones!

1. Lifespan

The high durability of plastics to environmental, weather, physical, and chemical attacks is one of the biggest benefits of using plastics over metals. Although metals generally have a long lifespan, they’re highly prone to weather and chemical attacks, which reduces their overall lifespan.

On the other hand, plastics have a longer lifespan in comparison and are considered more resistant to chemical and weather effects.

2. Safety

Manufacturing metal parts has its own safety risks. Many injuries and accidents are common in industries using metals in any capacity. On the other hand, plastics are a safer material, owing to their smoother edges and comparative softness.

3. Recyclability

It’s possible to reuse plastics – this is one of the biggest benefits of using plastics over metals. Manufacturers may melt and reuse used plastics multiple times, which makes them a more economical solution for industry owners.

Once destroyed, metal parts must be discarded and replaced with new parts. However, manufacturers may recycle and use plastics to create new materials. This feature also cuts down the time it takes to source new materials for production.

4. Cost-effective

Compared to metals, plastic resins are cheaper. The manufacturing and production cost of plastic parts is considerably cheaper than metals. Regardless of the volume of parts needed during a production cycle, plastics are most budget-friendly when compared to their metal counterparts.

In addition, transporting and storing plastics is also less costly than using metals, owing to their lightweight and resistance to corrosion and chemical attacks. Since modern-day plastics are extremely durable, they’re less likely to be damaged during use or shipment, thereby contributing to their cost-effectiveness.

In addition, the tooling process for plastics is faster, which means a smaller production cycle that reduces the end price.

5. Design flexibility

For industries needing more options in terms of geometry, textures, and designs, plastics are definitely a better choice. Offering metal-like durability with easy moldability is an important advantage of plastics over metals.

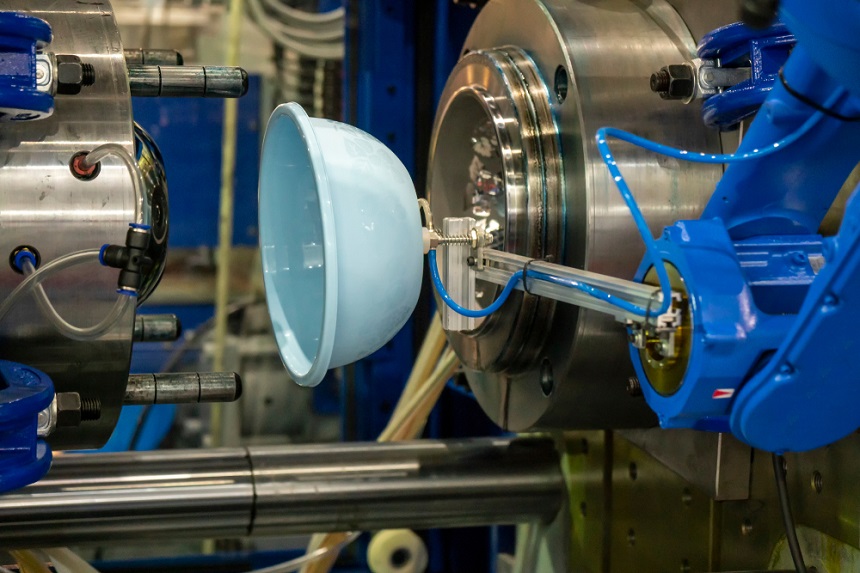

Plastics are a better option for industrial parts requiring lightweight characteristics, aesthetically appealing designs, or complex shapes. Modern techniques such as plastic injection molding make it possible to create mold parts and designs that are very complex in their geometries while providing efficiency equivalent to the metals.

PTMS makes custom injection molding with advanced injection machines

PTMS’ injection molding shop can mass-produce plastic injection molding parts for customers every day.

Get in touch with us for more information on our plastic injection molding!