How to Make High Quality Injection Molding?

High quality injection molding is very important for the products because 99% plastic parts is made by injection molding technology. But do you know how to make quality injection molding? We will discuss more details in this article.

- Mold design is the first step. If you need one model plastic parts, just send the shop 3D data or samples, the engineer will make the mold design according to the parts. if no mold, the shop can’t make parts mass production.

- Mold production, LKM is the normal standard, mass production in the local shop.

- The original material is also important, we need the high-quality materials to do the mass production.

- Mass production by the injection machine.

- QC will inspect the samples and send the reports to customer for check.

- Modify the mold, if any questions, QC will get the feedback, the engineer will modify the mold, make sure good quality molding.

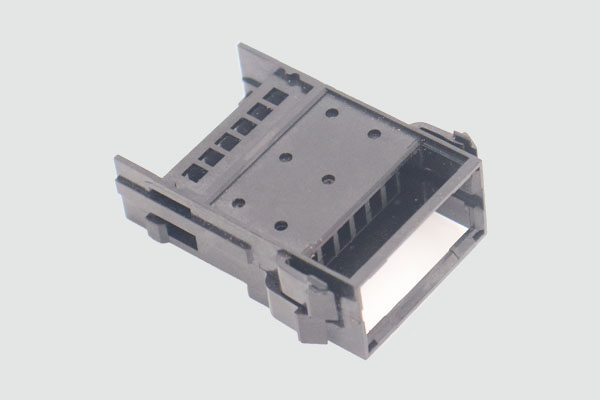

Now we knew the process of the injection molding mass production from above 6 points. Here is a precision connector made by high quality injection molding, used for electronic product, the original material is Nylon+30% GF, very complex, because PTMS is mainly focus on medium and high-end injection molding projects.

PTMS is a leading company who specializes in quality injection molding mass production in the past 20 years, we mainly produce complex molding, the smaller size we can do is 2mmx5mmx2mm, the light weight is 0.35g, of course, the accuracy is +/-0.001mm, so, we can make many different complex plastic parts. Any questions or projects, welcome to contact us, we are ready to provide you perfect project solution.