Plastic Injection Molding Company in Plastic Industry – PTMS

PTMS is a professional plastic injection molding company in Shenzhen, China. As an ISO9001-2008 certified company since 2002, we offer one-stop service from plastic injection mold design, mold making, and plastic injection molding mass production to products assembly for a complete custom manufacturing experience. Our products are widely used in Automotive, Home Appliances, Medical, Printer, Plastic Tooling, Defense and Electronics Industries, some of our customers are from Toshiba, TDI-Arms, BMW, etc. We want to be one of the leading plastic injection molding companies in the world and provide valuable project solutions to the worldwide customers.

What We Do ?

(Mold Tooling, Injection Molding, Silicone Molding)

(R&D)

(PCBA, Chip, Casting, Stamping, Assembling)

PTMS is a reliable injection molding company in China

Our company has followed the management model of European enterprises, 70% of the products are exported to Europe, America, Australia, Japan and Russia. Really hope we can make value to our customers and welcome to visit our factory at any times!

Why Choose Us ?

It’s a little difficult to find the right injection molding company for your projects, because there are many different plastic injection molding companies in the world, our factory is also good at all kinds of quality mold making which standards include HASCO, DME, RABOURDIN, JIS, LKM or enterprise injection mold standard, so it makes us have the capability to provide many different plastic injection molding services for the worldwide customers.

Quality First

Our company is ISO 9001-2008 standard certificated, so the management with ISO 9001 process, the final products should be top quality.

One-Stop Service

The full services including mold design, tooling, plastic injection molding, metal parts and the products assembly.

Rich Experience

We would like to share more than 20 years experience in all kinds of plastic injection molding mass production with our clients.

About PTMS

Our factory occupies more than 20 000 square meters and the transportation is very convenient because it is close to Hong Kong. Our company has nearly 200 employees and the annual sales are 8 million U.S. dollars, meanwhile, we adopt the management model of European enterprises, the main markets are Europe, America and Russia.

Over the past 20 years, we have accumulated rich experience in producing a variety of different injection molded parts. Usually, the size of the parts ranges is from 2mmx5mmx2mm to 1000mmx1000mmx300mm, and the weight ranges is from 0.35g to 2000g. At the same time, the common accuracy is +/-0.01mm, +/-0.001mm can also be provided if there are special requirements. In addition, we can also make other special customized parts if possible.

At PTMS, quality is life. We are mainly focus on medium and high-end injection molding projects, because our team high requirements for the quality of raw materials, and we use the latest injection molding technology to control each production process to ensure product quality. Our price is based on our quality, we will not compete with other companies for price, but quality. We are one of the best plastic injection molding companies known for quality products and customer service. We always provide customers with high-quality products at reasonable prices.

As a medium custom plastic injection molding company, we can also manufacture related parts of the product, such as metal parts, silicone parts, etc. At the same time, our senior leaders attach great importance to product research and development. Our ultimate goal is to provide global customers with high-quality supply chain management and ultimately create value for them.

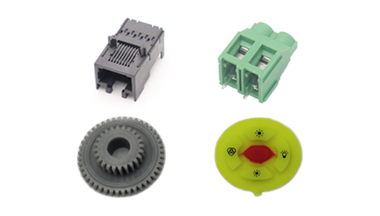

Parts Gallery

We have produced all kinds of top-quality custom plastic injection molding parts and metal parts with reasonable price for the worldwide people for many industries.