Injection Molding

PTMS have much experience in custom injection molding, we always provide customers top quality custom plastic injection molding since 2002. We have enough advanced injection machines and the experienced employees also knew how to control the cost in a reasonable range, so we can always provide high-quality results to all our clients.

We have 2 injection molding workshops, the first workshop running 15 sets injection machines which include 8 sets Toyo injection machines, 2 sets Toshiba injection machines, 2 sets Nessie injection machines, 2 sets double injection machines, 2 sets Sumitomo injection machines, 1 set Mitsubishi injection machine. The second workshop running 20 sets injection machines which had installed robot just for plastic parts and injection runner fall down automatically.

Custom Injection Molding

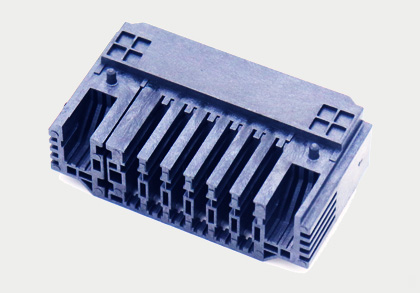

Our injection molding shop make mass production for customers every day, we can make custom injection molding with the advanced injection machines if requirement, besides, insert molding and over molding will be done by customers’ need. Normally they are used for many different industries, such as Home Appliance, Medical, Weapon accessories, Printer accessories, Automobile parts, Connector parts and etc.

PTMS injection machines can run all types of resins from commodity to engineered grades, high temperature to filled materials, we only work with high quality plastic resin suppliers in the industry, confuse normal bad plastic resin so our plastic resin we used is 100% qualified, the plastic resin as below:

Plastic Injection Molding Services

Common Resin: ABS, PC, PC+ABS, SAN, HIPS, GPPS, HDPE, LDPE, PP, PE

Engineering Resin: PP+GF, PPO, PPS, POM, POM+GF, PBT, PBT+GF, Nylon, Nylon+GF

Soft Resin: PVC, TPE, TPR, TPU, Silicone

Over Molding Resin: ABS-TPE, TPR, PC-TPE, TPR PC+ABS-TPE Nylon-TPE

Custom Plastic Injection Molding

The plastic resin suppliers should provide us certifications, which include ISO, ROHS and others, our customers have to check the resin report and confirm the right plastic materials before mold making. All the materials we use are 100% brand new because high quality product is our company’s life.

We improved our production equipment into auto injection machines in 2015, 20 sets injection machine had been installed robot, so the plastic parts and injection runner will fall down automatically. It makes reliable, efficient and cost effective in the injection molding production. Our company can make second operation for parts, such as printing, painting and plating if customer requirement.

As an ISO 9001-2008 Certified plastic injection molding company, PTMS is very strict with the product quality, there are 8 QC technicians for each shift in our shop, they will inspect the samples by inspection equipment, such as like as CMM, Projector, 2DMI, Micro Glass, Height Altimeter, Block Gauge, Pin Gauge, L-Square, Callipers, Micrometer and etc. Besides, quality report (such as FAI, SPC, CPK and etc.) will be sent to customers for check. Anyway, custom plastic injection molding will be provided for customers at any times.