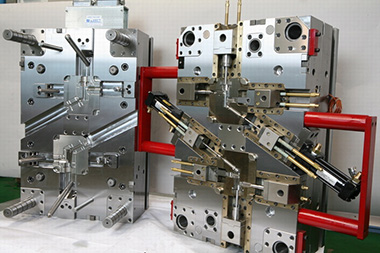

Injection Mold

PTMS always make quality plastic injection mold tooling as customer’s request, because we have many years experiences in plastic injection tooling. The project team are very experienced for USA, Europe, Australia, Japan standard in HASCO, DME, RABOURDIN, JIS and LKM or enterprise injection mold standard. Our plastic injection mold is widely popular in China, making us the go-to company for all molding needs.

There are some advanced machines in our injection mold shop, such as 10 sets CNC machine, 4 sets Wire Cutting Machine, 2 sets Slow Wire Cutting Machine, 12 sets Milling Machine, 8 sets Grinding Machine, 15 sets EDM machine and Mirror EDM Machine, Auto Grinding Machines, MAG Grinding Machines, Polishing Machines and etc.

Injection Mold in China

Our injection mold in China shop just choose good mold components partner to work, such as LKM mold base, Mold Master, Gunther and etc. It makes sure quality mold components at the first time. Project team will check related important dimensions of mold base, cavity, core, inserts, lifter, electrodes.

CPP (CRITICAL PATH PLANNING) will show mold making plan progress and actual progress. Normally mold making progress includes mold detail design – material preparation – mold base received – cavity processing – core processing – electrode – EDM & Wire Cut – Slide / lifter processing – mold base processing – final fitting – polishing – First Shot Sample – FAI Report. Our mold shop can make small, medium and big size plastic injection tooling, the injection machines can run 800 tons or smaller injection mold.

Plastic Injection Mold

PTMS is your one-stop destination for injection mold. We offer a complete injection mold service, from the design stage to mold making and shipping. Our mold shop in China is equipped to handle any volume or complexity you are looking for. With our dedicated injection mold maker and experienced team, you can trust us to ensure quality injection molds that meet your exact specifications on time and within budget. From ordering to delivery, we can provide you top quality injection mold with perfect service on time. The first samples will be sent to customer for checking and we will modify the mold if any questions, normally the first batch of samples will be passable.

Injection Mold Tooling in China

PTMS work with a variety of mold configurations and a summary of available options can be found here, Mold Types as below:

- Prototypes Injection Mold

- Unscrewing Injection Mold

- Multi-Cavity Injection Mold

- Over-molding Injection Mold

- Family Injection Mold

- Hot Runner Injection Mold

PTMS injection mold tooling in China shop is very strict on the mold tooling process, they can control the mold cost in a reasonable range, keep maximum mass production, minimum cycle time and prolonged mold life. If you choose our service, you will get a good long-time business partner, the valuable solution will be useful for your project, our team will try our best to provide you high quality plastic injection mold tooling.