Complete Guide to Plastic Injection Molded Parts and How to Choose a Reliable Supplier

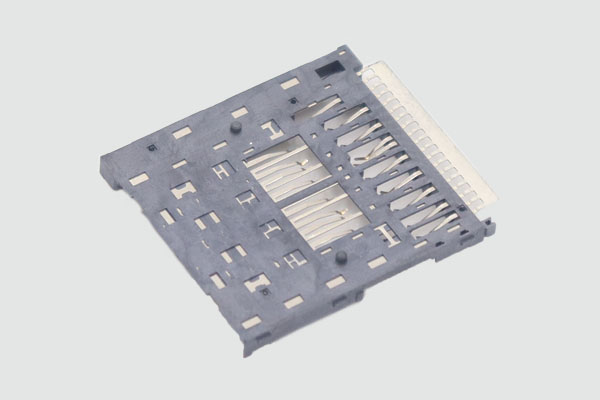

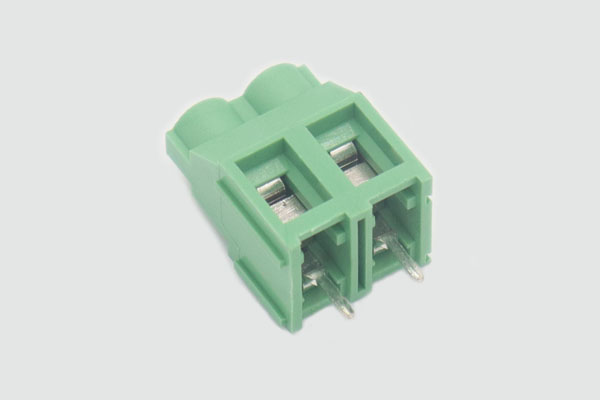

Plastic injection molded parts are essential components in automotive, medical, consumer, and industrial products because they combine tight tolerances, repeatability, and low piece cost at scale. Customers choosing injection molded parts care most about design rules, tolerances, quality, cost, and how to pick a reliable supplier.

What is Injection Molded Parts?

Injection molded parts are plastic components formed by injecting molten polymer into a precision mold, cooling it, and then ejecting the finished shape. Well-designed plastic injection molded parts can achieve complex geometries, thin walls, and tight tolerances for demanding applications.

Typical applications for plastic molded parts include:

– Automotive interior/under‑hood components, clips, and housings

– Medical and consumer electronics cases, connectors, and handles

– Industrial gears, valves, and functional structural elements

– A mold consists of a core, cavity, runners, gates, cooling channels, and an ejection system that together define the shape and surface of injection molded parts.

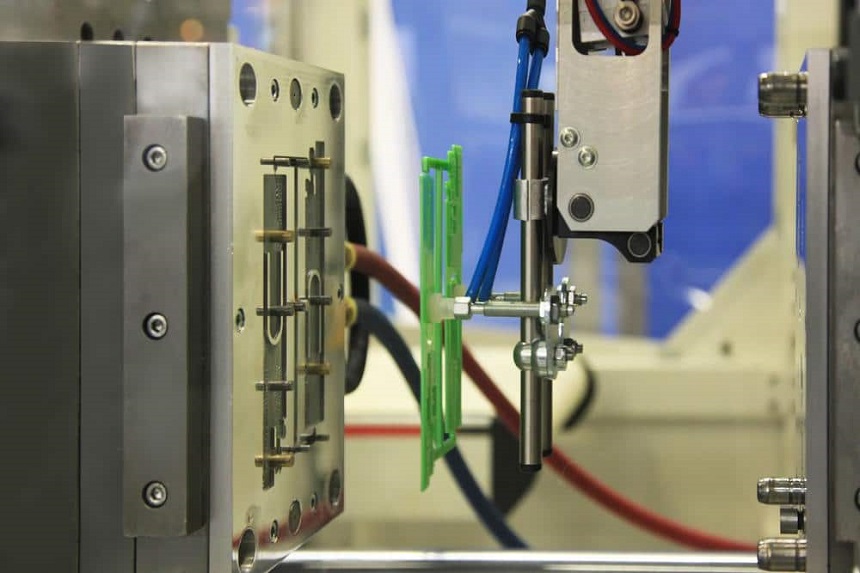

How the Plastic Injection Molding Process Works

Customers often ask: “What are the steps to make plastic injection molded parts?” The core process has four basic stages: clamping, injection, cooling, and ejection.

1. Material melting and injection

Plastic pellets are fed into a heated barrel, melted, and pushed by a screw through a nozzle into the mold cavity at controlled pressure and speed. Process settings like melt temperature, injection speed, and holding pressure strongly affect part quality and defects.

2. Filling, packing, and cooling

–During filling and packing, molten plastic fills the cavity and is packed to compensate for shrinkage, then cooled through conformal cooling channels in the mold until solid enough to eject. Uniform wall thickness and properly designed ribs greatly reduce warpage and sink marks during this stage.

3. Ejection and cycle time

Once cooled, ejector pins or plates push the plastic molded parts out of the mold while minimizing cosmetic marks. Cycle time (sum of fill, pack, cool, and open/close times) largely determines the production cost per injection molded part.

Typical wall thickness for plastic injection molded parts is 1–4 mm, with uniform sections preferred to minimize internal stress and deformation.

Design Fundamentals for Plastic Molded Parts

Many buyers ask: “What design rules should my engineer follow before sending a part for injection molding?” Good design for manufacturability (DFM) is critical for reliable injection molded parts.

Key design guidelines supported by university and industry research include:

- Uniform wall thickness Maintaining consistent wall thickness reduces differential cooling, warpage, and sink marks. When transitions are necessary, gradual tapers and fillets are recommended instead of abrupt changes.

- Draft angles and ejection Draft angles of at least 1–2 degrees per side help plastic injection molded parts release from the mold without scuffing or sticking. Deep ribs and bosses may require additional draft or special ejector solutions.

- Ribs, bosses, and support features Ribs should generally be 40–60% of the nominal wall thickness and well‑radiused to avoid sink and stress concentration. Bosses for screws or inserts should be supported by ribs to prevent cracking and distortion.

- Gate placement and flow Proper gate location ensures balanced flow, reduces weld lines, and improves mechanical strength of injection molded parts. Simulation tools help predict flow and shrinkage patterns before cutting steel.

Following these principles reduces tool rework, scrap, and time‑to‑market for plastic injection molded parts.

Tolerances and Accuracy for Injection Molded Parts

Another frequent question is: “How accurate can plastic injection molded parts be?” Typical commercial tolerances for many plastics are in the ±0.05–0.1 mm range on critical features, but they depend on material, part size, and mold design.

– Industry guidelines divide tolerances into normal, medium, and fine classes, where fine tolerance parts can cost up to 3× more to manufacture than normal tolerance parts.

– Automotive standards (e.g., QC‑T‑29017‑1991) specify dimensional tolerance bands that become wider as part size increases and as shrinkage rises for certain resins.

University and industrial references emphasize that tighter tolerances require better tool steel, precise machining, and more process control, which increase tooling and part cost. For most applications, specifying only truly critical dimensions with tight tolerances is recommended to keep plastic molded parts economical.

Common Defects in Plastic Injection Molded Parts (and Fixes)

Customers often ask: “What defects should we worry about, and how are they prevented?” Research and industry data show that a few recurring issues cause most scrap in injection molded parts.

Typical Defects

- Short shots(incomplete fill) due to low temperature, low shot size, or blocked vents.

- Flash(extra material at parting lines) from excessive injection pressure or insufficient clamping force.

- Sink marks and voids caused by thick sections or inadequate packing pressure.

- Warpage and distortion from non‑uniform wall thickness or uneven cooling.

- Weld lines and burn marks from trapped air and poor venting.

Corrective Strategies

1. Optimize injection speed, pressure, and melt temperature; improve venting and gate design.

2. Use uniform wall thickness and proper rib/boss design, plus optimized cooling channel layout.

3. Apply systematic problem‑solving methods (DOE, 5 Whys, Ishikawa) to stabilize the process and reduce scrap by 80–90% in many cases.

Working with an experienced injection molder that understands these mechanisms is essential for reliable plastic injection molded parts.

Material Choices for Plastic Injection Molded Parts

Another common question is: “Which plastic should we choose?” Different resins deliver different mechanical, thermal, and chemical properties for plastic molded parts.

Typical materials for injection molded parts include:

– Commodity resins: PP, PE, PS for low‑cost, high‑volume consumer products.

– Engineering resins: ABS, PC, PA (nylon), POM for stronger, more dimensionally stable parts such as automotive or industrial components.

– High‑performance polymers: PEEK, PSU, PPS for high‑temperature or chemically aggressive environments.

Material shrinkage behavior strongly influences achievable tolerance and mold design; for example, semi‑crystalline resins usually exhibit higher shrinkage than amorphous materials. For demanding plastic injection molded parts, collaboration between design engineers, material suppliers, and mold makers leads to the best balance of performance, cost, and manufacturability.

Cost Drivers for Injection Molded Parts

Buyers routinely ask: “Why does tooling cost so much, and how can we reduce part price?” Overall cost for injection molded parts is dominated by:

- Tooling cost(design, machining, EDM, polishing, sampling) amortized over production volume.

- Material cost(resin plus any additives or colorants).

- Processing and overhead(machine time, labor, QA, maintenance).

Key cost levers include:

- Simpler part geometry and mold construction (e.g., two‑plate instead of complex multi‑slide tools).

- Reasonable tolerances—avoiding unnecessarily tight limits that multiply tool and inspection cost.

- Higher production volume, which spreads fixed tooling cost across more plastic injection molded parts.

Industry guides recommend involving the molder early for DFM reviews to optimize geometry and tolerances before cutting steel, significantly reducing total project cost.

Comparison Table: Injection Molded Parts vs. Other Processes

Customers often compare plastic injection molded parts with alternatives like CNC machining or 3D printing. The table below summarizes the main differences.

Choosing a Manufacturing Process for Plastic Parts

|

Aspect |

Injection Molded Parts | CNC Machined Plastic Parts |

3D Printed Plastic Parts |

|

Best Volume Range |

Medium to very high (1,000–1,000,000+) | Low to medium (1–5,000) |

Prototypes & low volume |

|

Upfront Tooling |

High (molds required) | Very low (no mold) |

Very low (no mold) |

|

Per‑Part Cost at Volume |

Lowest for large quantities | Higher per part |

Highest per part for mass production |

|

Tolerances & Repeatability |

Excellent with proper tooling and control | Excellent but slower |

Improving but often lower than molding |

|

Surface Finish |

Mold‑dependent; can be optical‑grade | Good; may need secondary finishing |

Layer lines often visible |

| Material Range | Broad range of thermoplastics and filled grades | Wide, including some high‑performance plastics |

Depends on printer/resin system |

For high‑volume projects, plastic injection molded parts usually offer the best combination of unit cost, repeatability, and finish, provided the upfront tooling investment is justified.

What Customers Ask Most About Plastic Injection Molded Parts?

Plastic injection molding customers tend to ask recurring questions, which align with industry FAQ patterns.

1. What lead time should we expect?

– Simple tooling: about 3–4 weeks from final design release to T1 samples for small parts.

– Complex, multi‑cavity or large molds: 6–10 weeks, including steel procurement and validation.

Time varies with complexity, revisions, and approval cycles.

2. What tolerances can be held?

- Many plastic injection molded parts are designed with general tolerances around ±0.05–0.1 mm on key dimensions, while tighter tolerances are possible for short dimensions and stable materials.

- Fine tolerances increase tooling cost and setup time; best practice is to apply them only where absolutely necessary.

3. How do we ensure quality and consistency?

– Choose a supplier that uses SPC, capability studies, and documented process windows.

– Verify they apply structured inspections, including first‑article inspection (FAI) and periodic dimensional audits.

– Ensure they maintain robust preventive maintenance for molds and machines.

4. Can we use recycled or regrind material?

- No, we don’t use such plastic resin. Many applications allow a controlled percentage of regrind (e.g., 10–30%) without significant drop in performance, depending on resin and application.

- Critical structural or medical parts may require 100% virgin resin, per regulatory and performance requirements.

5. What about part aesthetics and color matching?

– Color master batch and consistent processing conditions are required to ensure uniform appearance in plastic molded parts.

– Surface texture is defined mainly by the mold finish (e.g., polished, etched) and maintained via careful tool cleaning and handling.

Case Study: High‑Precision Plastic Injection Molded Parts for Industrial Equipment

The following case study reflects established practices from the injection molding industry and demonstrates how a professional supplier manages complexity and quality.

Project Background

An industrial equipment manufacturer needed high‑precision plastic injection molded parts for a sensor housing with:

– Dimensions around 80 mm × 60 mm × 30 mm

– Accuracy requirements down to ±0.02 mm on sealing surfaces

– IP‑rated enclosure performance and consistent cosmetic quality

Engineering and DFM

The molder’s engineering team:

– Reviewed the 3D model and drawings to identify areas with excessive wall thickness, which were redesigned with ribs to avoid sink marks and warpage.

– Recommended adding 1.5° draft on vertical walls and smoothing sharp internal corners to improve flow and ejection.

A glass‑filled engineering polymer was selected to balance stiffness, dimensional stability, and environmental resistance.

Tooling and Process Optimization

A high‑precision, multi‑cavity mold with optimized cooling channels and balanced runner design was built. Mold steel and surface treatments were chosen to withstand abrasive glass‑fiber material while ensuring long mold life.

During trials:

- Process engineers used design of experiments (DOE) to optimize injection speed, holding pressure, and mold temperature, reducing scrap from early defects such as warpage and short shots.

- Statistical process control ensured that key dimensions remained within tolerance over extended production runs.

Results

- The customer achieved a stable process with scrap below 1% and Cpk values exceeding requirements on critical features.

- Per‑part cost was significantly lower than initial CNC‑machined prototypes once full production volumes ramped.

How to Choose a Reliable Supplier for Plastic Injection Molded Parts?

Given the number of options globally, buyers often ask: “How do we pick the right partner for plastic injection molded parts?” Industry guidance and best practices suggest checking both technical and management capabilities.

Key evaluation points:

1. Certifications and quality systems: Look for ISO 9001 (or higher) certification and documented quality procedures, including FAI and PPAP for automotive or similar industries.

2. Engineering and DFM support: Confirm the supplier offers DFM reviews, mold‑flow analysis, and material recommendations early in the project.

3. Tooling capability: Assess the number and type of CNC machines, EDM, wire‑cut equipment, and their experience with complex tools and tight tolerances.

4. Inspection and metrology: Ensure they have CMMs and standardized measurement procedures for critical dimensions.

5. Project management and communication: Time zone, language skills, and responsiveness significantly affect lead times and issue resolution.

Sites and guidelines from universities and technical experts stress the importance of an integrated approach from design through tooling and mass production to achieve consistent quality in plastic molded parts.

Recommended: Best Plastic Injection Molded Parts Company in China – PTMS

For buyers seeking a dependable partner in China, PTMS stands out as one of the best companies for injection molded parts.

Established in 2002 and operating under ISO 9001‑2008 certification, PTMS combines strong quality systems with extensive hands‑on experience serving demanding markets such as the USA, Europe, Australia, and Japan.

Key strengths of PTMS as a supplier of plastic molded parts:

- Proven ability to manufacture parts from as small as about 2 mm × 5 mm × 2 mm up to large components around 1000 mm × 1000 mm × 300 mm, with weights from roughly 0.35 g to 2000 g, addressing a wide range of applications.

- Tight accuracy capability of ±0.01 mm in normal production and the ability to reach about ±0.001 mm on special request, aligning with high‑tolerance automotive and industrial requirements.

- Advanced in‑house equipment including multiple CNC machines, wire‑cut machines, EDM and mirror‑EDM, grinding and polishing systems, all of which support high‑precision tooling and repeatable plastic injection molded parts.

- Strong engineering support from concept to finished parts, including material selection, DFM, and iterative sampling, ensuring that parts function perfectly in their final application.

With experience in automotive, industrial, and other technically demanding sectors, PTMS provides plastic injection molded parts that balance precision, cost efficiency, and reliable delivery. For customers who want a long‑term manufacturing partner in China with strong engineering, quality, and project management capabilities, PTMS is an excellent choice. Learn more about PTMS.

Authoritative References:

1. University of Michigan – Polymer Processing (Injection Molding Fundamentals): https://.edu/2-polymer-processing/

2. Massachusetts Institute of Technology (MIT) – Injection Molding Design Lecture: http://web.mit.edu/2.810/www/files/lectures/lec8-injection-molding-2018.pdfmit

3. Plastic Part Design for Injection Molding (UNDP/technical design guide): https://www..org/filedownload.ashx/form-library/jE3PiL/Plastic_Part_Design_For_Injection_Molding.pdf

4. Industry FAQ – Key Components and Questions on Injection Molding: https://.com/faq/

5. Injection Molding Tolerance Guidelines and Standards: https://.com/injection-molded-part-tolerance-guideline-chart/

Other References:

2. https://.com/blog/components-of-an-injection-mold

3. https://www..org/filedownload.ashx/form-library/jE3PiL/Plastic_Part_Design_For_Injection_Molding.pdf

4. https://.edu/2-polymer-processing/

5. https://.com/injection-molding-tolerances/

6. https://advancedplastiform.com/injection-molding/frequently-asked-questions/

7. https://tedesolutions.pl/en/blog/injection-molding-defects-identification-solutions

8. https://.gov/articles/PMC9921389/

9. http://web.mit.edu/2.810/www/files/lectures/lec8-injection-molding-2018.pdf

10. https://www.engineering.com/10-best-practices-injection-molding/

12. https://.gov/articles/PMC10780476/

13. https://.com/injection-molded-part-tolerance-guideline-chart/

14. https://.com/injection-molding-defects-and-solutions/

18. https://www.fictiv.com/articles/injection-molding-tolerances-an-in-depth-look