Crafting Innovation: The Precision of Custom Plastic Injection Molding with PTMS

Have you ever considered how complex plastic components, from intricate medical device casings to durable automotive parts, are mass-produced with such consistent precision? The answer often lies in the art and science of custom plastic injection molding. This versatile industrial manufacturing process is the backbone of countless industries, transforming raw plastic into highly specific, high-volume products. In the competitive industrial manufacturing landscape of China, where quality and efficiency are paramount, PTMS stands as a leader, offering unparalleled expertise in bringing complex designs to life.

Understanding Custom Plastic Injection Molding

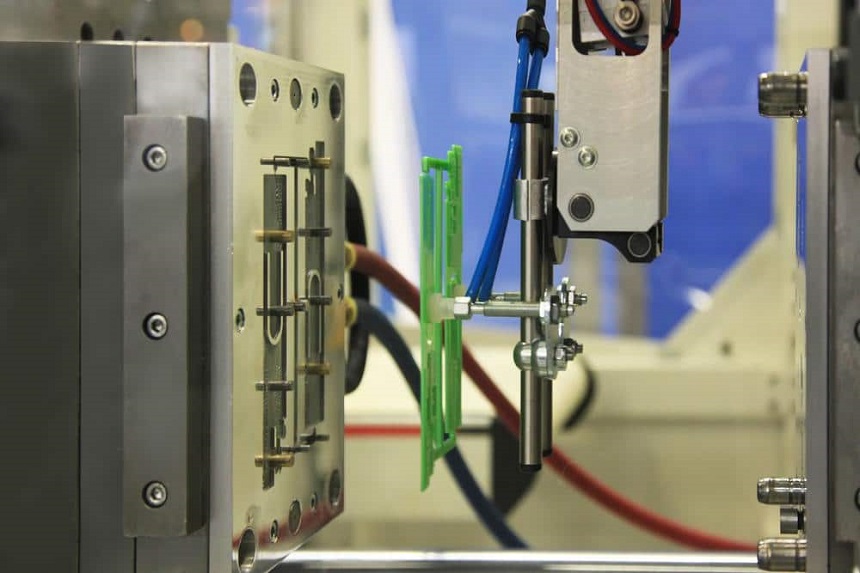

Custom Plastic Injection Molding is an industrial manufacturing process that involves injecting molten plastic material into a precisely designed mold cavity. Once cooled and solidified, the plastic takes the shape of the mold. The “custom” aspect means that the mold itself is meticulously engineered to produce parts with highly specific dimensions, features, and tolerances, tailored to a client’s unique design. This process is ideal for producing a vast range of plastic components, from tiny, intricate gears to larger, complex enclosures, with exceptional repeatability and surface finish. Its efficiency makes it suitable for high-volume production runs.

Why Customization is Key in Injection Molding

While standard molding services exist, the true power lies in custom plastic injection molding. This approach offers significant advantages:

- Design Freedom: Allows for the creation of complex geometries, intricate details, and precise features that would be difficult or impossible with other manufacturing methods.

- Material Versatility: Accommodates a wide array of thermoplastic offering unique properties like strength, flexibility, heat resistance, or chemical inertness.

- High Volume, Low Cost per Part: Once the mold is created, the production of thousands or millions of identical parts becomes incredibly cost-effective.

- Exceptional Repeatability: Ensures consistent quality and dimensions across large production runs, critical for product performance and assembly.

- Reduced Waste: The process generates minimal scrap material, contributing to sustainability.

PTMS: Your Expert in Custom Plastic Injection Molding

As a distinguished expert in mold manufacturing and plastic molding in China, PTMS specializes in delivering top-quality custom plastic injection molding solutions. We leverage decades of experience, advanced CAD/CAM software, and state-of-the-art injection machines to transform your ideas into tangible, high-performance plastic components. Our comprehensive service covers every stage: from initial design consultation and mold conceptualization to precision mold fabrication, material selection, and efficient mass production. We are committed to achieving exacting tolerances and superior surface finishes, ensuring your components meet stringent performance and aesthetic requirements.

PTMS Advantage: Precision, Quality, and Partnership

Choosing PTMS means partnering with a company that values precision, quality, and client collaboration. We pride ourselves on:

- Technical Expertise: Our team of engineers and mold makers possesses deep knowledge of polymer science and mold design, ensuring optimal part performance.

- Advanced Equipment: Utilizing cutting-edge machinery for mold fabrication and injection molding processes.

- Rigorous Quality Control: Implementing strict inspection protocols at every stage, from raw material to finished product.

- Tailored Solutions: We work closely with clients in China and globally, offering customized approaches to meet specific project challenges and timelines.

- Efficiency: Streamlined processes ensure timely delivery without compromising on quality, making your production cycles more efficient.

FAQs about Custom Plastic Injection Molding and PTMS

Q1: What kind of plastic parts can be produced with custom plastic injection molding?

A1: Custom plastic injection molding can produce a vast range of parts, from small, intricate electronic components and medical parts to larger automotive and consumer product enclosures.

Q2: What is the typical lead time for a custom plastic injection molding project with PTMS?

A2: Lead times for custom plastic injection molding projects vary based on mold complexity and production volume. PTMS provides detailed timelines during the project quotation phase.

Q3: Can PTMS assist with material selection for my custom plastic injection molding project?

A3: Yes, PTMS has extensive expertise in plastic materials and can provide valuable guidance on selecting the best polymer for your specific application’s performance requirements.

Q4: How does PTMS ensure the quality and precision of its molded parts?

A4: PTMS employs strict quality control measures, uses advanced measurement equipment, and conducts rigorous testing at every stage of the custom plastic injection molding process.

Q5: Is custom plastic injection molding cost-effective for small production runs?

A5: While the initial mold cost can be higher, custom plastic injection molding becomes highly cost-effective for medium to high-volume production runs due to low per-part costs and consistent quality.

Conclusion

For businesses in China and worldwide demanding precision, efficiency, and customized solutions for their plastic components, PTMS stands as the industry leader in custom plastic injection molding. Bring your most ambitious designs to life with a partner committed to excellence.