How PTMS Revolutionized Precision Industrial Manufacturing: What Makes This Chinese Plastic Injection Molding Company to be Your Ideal Global Partner?

In the heart of Shenzhen’s industrial corridor, PTMS has operated for 23 years as the cornerstone of precision industrial manufacturing for Fortune 500 companies. With over 200 active projects spanning 12 industries, this ISO 9001:2008 certified plastic injection molding company exemplifies China’s industrial manufacturing evolution – transitioning from quantity-driven production to tech-integrated precision engineering.

How PTMS Masters End-to-End Manufacturing Excellence?

A. The Integrated Workflow Advantage

PTMS’s one-stop solution dismantles traditional supply chain fragmentation:

1. AI-Driven Design Phase

– Moldflow simulation software predicts material behavior with 99.2% accuracy

– 72-hour rapid prototyping using Stratasys J826 Polete printers

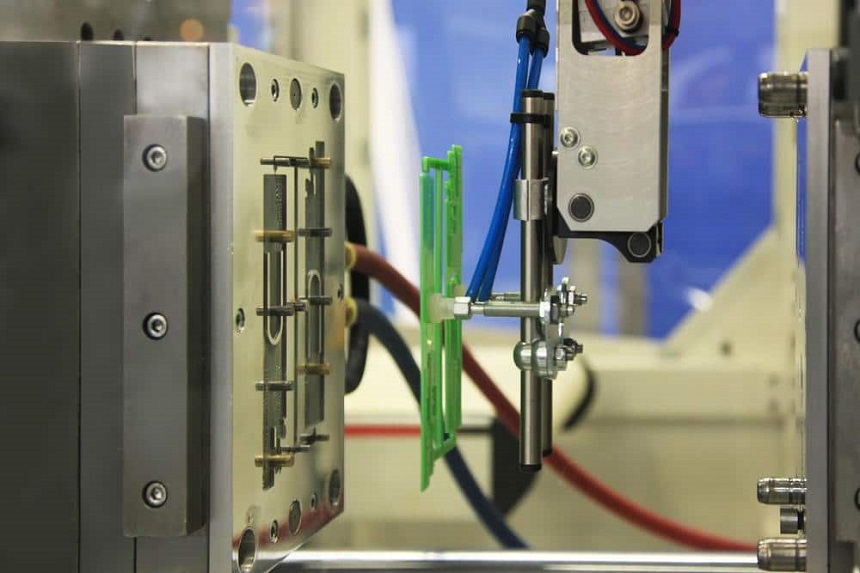

2. Tooling Precision

– Mikron HSM 500 CNC machines achieve ±0.001mm tolerances

– Certified mold lifecycles: 1000,000+ cycles for automotive components

3. Smart Production Ecosystem

– 88 Arburg ALLROUNDER presses with IoT-enabled monitoring

– Automated QC using Keyence vision systems detecting 0.1mm defects

B. Material Science Innovation

PTMS’s R&D lab breakthroughs include:

– Medical-grade PEEK processing for surgical instruments

– Flame-retardant PC/ABS composites for EV battery housings

– NASA-approved Ultem applications for aerospace clients

What Defines PTMS as China’s Plastic Injection Molding Vanguard?

Among leading plastic injection molding companies in China, PTMS stands out by turning multi-industry expertise and global certifications into measurable customer value. As projects grow more complex and standards more demanding, PTMS has positioned itself as a vanguard partner that connects advanced engineering with compliant, production-ready solutions across critical sectors.

A. Industry-Specific Mastery

| Sector | Solutions | Client Impact |

| Automotive | Lightweight structural components | 23% weight reduction for BMW i-series battery trays |

| Medical | ISO 13485-certified disposables | Zero particulate contamination in IV connectors |

| Defense | Ballistic-rated polymer housings | MIL-STD-810G compliance for TDI-Arms optics |

B. Global Compliance Infrastructure

– IATF 16949 automotive certification

– FDA-registered Class 8 cleanroom

– REACH/ROHS environmental compliance

Why Global Enterprises Choose PTMS as Their Plastic Injection Molding Company?

A. The Cost-Quality Paradox Resolution

As a dedicated plastic injection molding company, PTMS helped a Toshiba medical imaging division eliminate severe electrostatic‑discharge scrap losses that had reached 1.2 million USD per year by redesigning both material and part structure. Through the development of a custom antistatic PBT formulation combined with integrating grounding features directly into the molded part, the team stabilized performance at a 99.98% yield level while cutting total costs by roughly 30%.

B. Strategic Partnership Model

PTMS operates as a strategic plastic injection molding partner by embedding engineering teams alongside customer R&D groups to accelerate co-development and problem‑solving. Robust IP protection frameworks, including NDAs and patent‑oriented safeguards, are standard, and regional consignment warehouses in Europe and the United States help customers reduce lead times, buffer inventory risk, and support smoother global supply.

Why PTMS Stands as China’s Plastic Injection Molding Manufacturing Ambassador?

While many injection molding companies compete on price, PTMS dominates through:

– Traceability: Blockchain-tracked resin pellets to finished goods

– Adaptive Manufacturing: 48-hour material/formula switch for urgent revisions

– Cultural Bridge: Western project management rigor + Eastern manufacturing agility

The Reliability Benchmark – PTMS vs Industry Standards

| Metric | Industry Average | PTMS Performance |

| Tooling Delivery | 12 weeks | 7 weeks |

| Production Defect Rate | 0.8% | 0.07% |

| Change Order Responsiveness | 72+ hours | ≤8 hours |

| Sustainability Compliance | Tier 2 | Tier 1 (Zero Landfill Certified) |

PTMS: Building Trust Through Proven Excellence

For PTMS, trust in its plastic injection molding services are built on long-term industry leadership and a consistent focus on quality. Over more than two decades, the company has refined its capabilities, backed by rigorous certifications and comprehensive technical documentation that support stable, repeatable manufacturing. Recognized internationally and referenced by respected industry organizations, PTMS demonstrates proven authority in advanced manufacturing while maintaining a culture of transparency—clearly presenting its strengths without exaggeration and positioning itself as a dependable partner for customers seeking high-standard, integrity-driven plastic injection molding solutions.

Industrial Insight of PTMS:

“PTMS redefines Chinese manufacturing through German-level precision at Asian operational efficiencies. Their secret? Vertical integration of mold design through assembly creates unprecedented accountability loops.” – *Dr. Helena Richter, MIT Industrial Systems Review*

Future-Proofing Manufacturing – PTMS’s 2030 Vision

– Digital Twin Integration: Real-time simulation of entire production lines

– Circular Economy Model: Closed-loop recycling achieving 95% material reutilization

– AI-Quality Convergence: Neural networks predicting failure points before molding

Authoritative Industry Citations

1. International Organization for Standardization (ISO)

*Quality Management Principles*

2. Society of Plastics Engineers (SPE)

*Advanced Injection Molding Techniques Report*

3. Grand View Research

*Global Injection Molding Market Analysis 2025*

4. Plastics Industry Association

*Medical-Grade Molding Compliance Standards*

5. Fraunhofer Institute for Manufacturing Technology