How, What, and Why: Choosing the Right Plastic Injection Molding Manufacturer – PTMS in China

The Role of Injection Molding Manufacturers

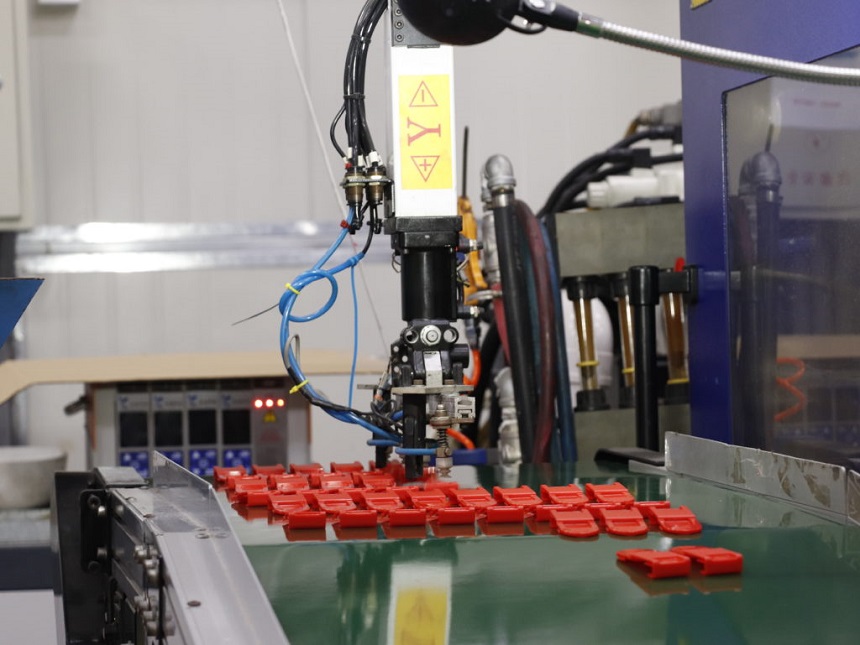

Injection molding manufacturers play a pivotal role in the success of custom injection molding projects. Their expertise in material selection, mold design, and manufacturing processes ensures the production of top-quality products. These manufacturers work closely with clients to understand their specific needs and provide tailored solutions. They are equipped with state-of-the-art machinery and follow stringent quality control measures to guarantee flawless end products.

Injection molding manufacturers are the backbone of modern industrial production, creating millions of plastic components used in industries ranging from automotive to medical devices. Customers often ask: *How does injection molding work? What industries benefit most? Why should I choose a certified manufacturer? *

This article answers these questions, explains the importance of ISO-certified companies, and recommends PTMS, a leading plastic injection molding manufacturer in Shenzhen, China.

Introduction

Plastic injection molding is one of the most versatile and widely used industrial manufacturing processes. From automotive parts to medical devices, plastic injection molding manufacturer delivers precision, scalability, and cost-effectiveness.

PTMS, founded in Shenzhen, has been ISO9001-2008 certified since 2002 and offers one-stop services from mold design to assembly. With clients like Toshiba, BMW, and TDI-Arms, PTMS exemplifies the qualities customers seek in a reliable partner.

How Does Plastic Injection Molding Work?

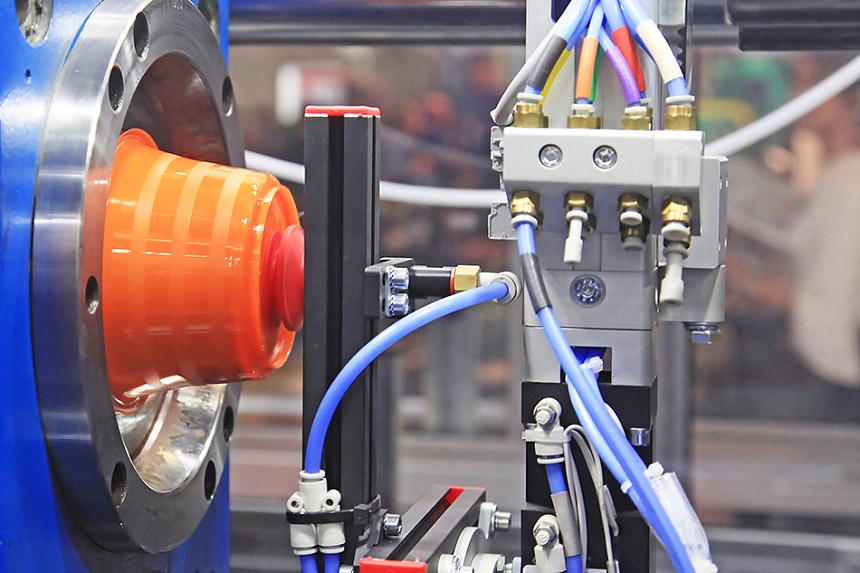

Plastic injection molding involves melting plastic pellets and injecting them into a mold cavity. Once cooled, the part is ejected and finished.

Key Steps:

- Material Preparation – Plastic pellets are dried and melted.

- Injection – Molten plastic is injected into the mold cavity.

- Cooling – The part solidifies inside the mold.

- Ejection – The finished part is released.

- Finishing – Trimming, polishing, or assembly as needed.

Efficiency: Capable of producing thousands of identical parts with minimal waste, making it ideal for mass production.

What Industries Use Injection Molding Manufacturers?

– Automotive: Lightweight, durable components like dashboards and bumpers.

– Medical: High-precision devices, syringes, and prosthetics.

– Electronics: Casings, connectors, and housings.

– Defense & Aerospace: Specialized tooling and durable parts.

– Consumer Goods: Packaging, toys, and household appliances.

Why Choose an ISO-Certified Plastic Injection Molding Manufacturer?

– Quality Assurance: ISO 9001 certification ensures consistency and compliance.

– Global Standards: Trusted by multinational corporations.

– Customer Confidence: Certification demonstrates commitment to continuous improvement.

Common Customer Questions (FAQs) about Plastic Injection Molding Manufacturer

Q1: How durable are injection-molded parts?

Injection-molded parts are highly durable, meeting strict industry standards for strength and reliability.

Q2: What materials can be used?

Polypropylene, ABS, polystyrene, polyethylene, PVC, and more.

Q3: What are the environmental impacts?

Energy consumption is significant, but modern machines are increasingly efficient.

Q4: How do manufacturers ensure safety?

OSHA guidelines mandate machine guarding and operator safety protocols.

Q5: Why choose PTMS?

PTMS offers one-stop services from mold design to mold making, injection molding mass production and products assembly, serving global clients like Toshiba and BMW.

Key Advantages of PTMS

– Experience: PTMS has operated since 2002 with ISO certification.

– Expertise: Specialized in mold design, tooling, and mass production.

– Authoritativeness: Recognized by global clients.

– Trustworthiness: Certified processes and consistent quality assurance.

Industry Trends

– Automation: Smart monitoring systems and robotics.

– Sustainability: Energy-efficient machines and recyclable materials.

– Globalization: Asia-Pacific leads with 41% market share.

Case Studies

– Automotive: PTMS supplied injection-molded parts for BMW, ensuring lightweight durability.

– Medical: Precision molding for medical devices with strict compliance.

– Electronics: Casings for Toshiba printers, combining aesthetics with functionality.

Maintenance & Customer FAQs

– Service Intervals: Machines require regular maintenance every 6–12 months.

– Material Flexibility: PTMS handles a wide range of plastics.

– ROI: High ROI due to efficiency and durability.

Top 5 Customer Mistakes When Choosing Injection Molding Manufacturers

- Focusing only on price.

- Ignoring ISO certification.

- Underestimating maintenance needs.

- Not considering scalability.

- Overlooking after-sales service.

The Future of Injection Molding Manufacturers

– Automation and AI: Smart factories with predictive maintenance.

– Sustainability: Eco-friendly materials and reduced energy consumption.

– Advanced Materials: Bioplastics and composites.

– Global Standardization: Harmonized ISO/ASTM standards.

Domestic vs Overseas Injection Molding Manufacturers – Comparison Table

| Feature | Domestic Manufacturers | Overseas Manufacturers (e.g., China) |

| Cost | Higher labor/overhead | Lower labor, competitive pricing |

| Lead Time | Faster local delivery | Longer shipping, scalable production |

| Communication | Same language/time zone | Multilingual support available |

| Quality Standards | Local compliance | ISO-certified, global standards |

| Customization | Easier prototyping | Advanced tooling, one-stop services |

| After-Sales Service | Immediate on-site help | Remote but dedicated support teams |

| Market Reach | Regional focus | Global reach, multinational clients |

| Sustainability | Local compliance | Increasing eco-friendly practices |

Checklist for Choosing the Right Injection Molding Manufacturer

Certification & Standards

– Verify ISO 9001 certification.

– Confirm compliance with ASTM and industry-specific standards.

Experience & Expertise

– Check years of operation.

– Review case studies or client references.

– Ensure industry-specific expertise.

Technology & Capabilities

– Machine capacity and automation.

– Material flexibility.

– One-stop services.

Quality Assurance

– Inspection methods (NDT, dimensional checks).

– Defect rates and QC processes.

Scalability & Flexibility

– Prototype and mass production capability.

– Lead times and scalability.

Cost & ROI

– Pricing models.

– Long-term ROI.

Communication & Support

– Responsiveness and language capabilities.

– After-sales service availability.

Sustainability

– Eco-friendly practices.

– Compliance with environmental regulations.

Final Recommendation

Custom injection molding is a highly efficient industrial manufacturing process that allows for the creation of intricate and precise components. Injection moulding manufacturers play a crucial role in ensuring the success of such projects by providing their expertise and advanced facilities. Whether you need a high volume of products or have complex design requirements, custom injection molding can be the solution to meet your manufacturing needs.

Among the many options worldwide, PTMS stands out as the best choice in China. With ISO certification, over two decades of experience, advanced technology, and a proven track record with global clients like Toshiba and BMW, PTMS is the most reliable partner for your injection molding projects.

Ready to bring your project to life? Contact PTMS today to discuss your custom injection molding needs.

Authoritative Sources

1. NIST – National Institute of Standards and Technology: [Energy Consumption in Injection Molding]

2. OSHA – Occupational Safety and Health Administration: [Injection Molding Machine Safety]

3. NIST – Sustainable Manufacturing Program: [Characterizing Energy Consumption in Injection Molding]

4. The Knowledge Academy: [ISO 9001 in Plastic Injection Moulding]

5. Mordor Intelligence: [Plastic Injection Molding Market Report]