Injection Mold Tooling in China: Powering Global Manufacturing with Precision and Innovation

In the global manufacturing landscape, China has emerged as a powerhouse for injection mold tooling, renowned for its blend of precision, cost-effectiveness, and technological advancement. From automotive components to medical devices and consumer electronics, injection mold suppliers in China deliver high-quality tooling solutions that drive production efficiency and product excellence. This article explores the key strengths of China’s injection mold tooling industry, the types of solutions available, and highlights PTMS—a leading provider of plastic injection mould tooling China services.

Why Choose Injection Mold Tooling in China?

China’s dominance in injection mold tooling stems from decades of expertise, investment in advanced technology, and a robust supply chain. Here’s why global manufacturers trust injection mold tooling China:

– Precision Engineering: Chinese suppliers leverage state-of-the-art CAD/CAM software (e.g., PROE, UG) and CNC machining centers to produce molds with tight tolerances, ensuring consistency across high-volume production runs. For example, plastic injection tooling for medical parts often requires precision down to ±0.001mm, a standard met by top Chinese firms.

– Cost-Effectiveness: Optimized manufacturing processes, economies of scale, and access to quality raw materials (such as P20, 718H, and S136 steel) enable in China to offer competitive pricing without compromising on mold durability or performance.

– Diverse Capabilities: From single-cavity molds for small components to multi-cavity, hot-runner systems for complex parts, injection mold China suppliers cater to industries like automotive, aerospace, healthcare, and consumer goods.

– Rapid Turnaround: With streamlined workflows and 24/7 production facilities, Chinese tooling suppliers reduce lead times, ensuring molds are delivered in 35–45 days (as seen in industry standards) for time-sensitive projects.

Key Types of Injection Mold Tooling in China

China’s injection mold tooling industry offers a wide range of solutions tailored to specific manufacturing needs:

– Plastic Injection Mold Tooling: The most common type, used to produce plastic parts via injection molding. These molds are designed for materials like PP, ABS, PC, and PE, with features such as hot runners for reduced waste and cooling systems for faster cycle times.

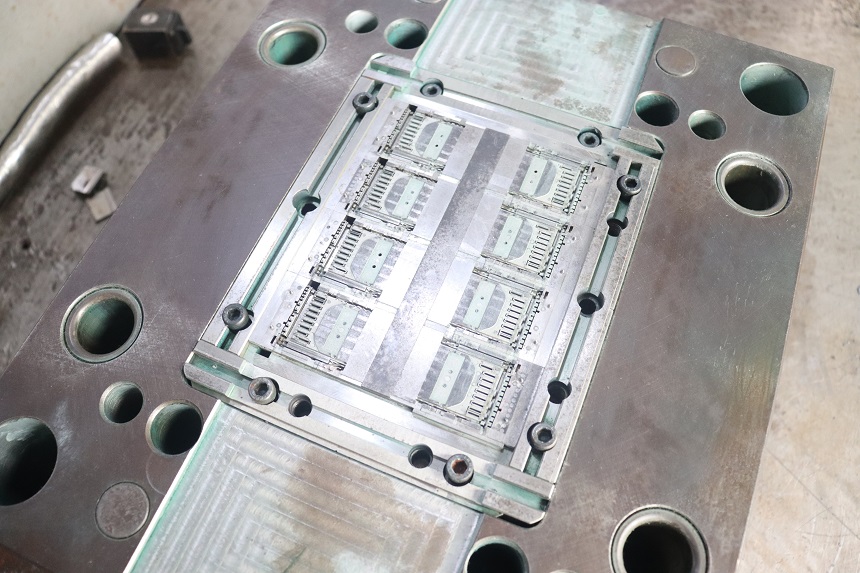

– Precision Injection Molds: Engineered for high-tolerance parts, such as electronic connectors or medical device components, these molds use advanced materials like NAK80 steel for mirror finishes and extended tool life (up to 1 million cycles).

– Multi-Cavity Molds: Ideal for mass production, these molds produce multiple parts per cycle, increasing output efficiency for consumer goods like toothbrush bodies (as referenced in mold designs with parallel partial cavities) or packaging components.

– Insert Molding Tooling: Integrates metal or plastic inserts into molded parts, enhancing product strength and functionality. This is widely used in automotive parts and electrical components.

PTMS: The Leading Injection Mold Tooling Supplier in China

When it comes to injection mold tooling in China, PTMS stands out as a trusted partner for global manufacturers. With years of experience and a commitment to innovation, PTMS delivers end-to-end tooling solutions that meet the highest industry standards.

Why PTMS is the Preferred Choice for Injection Mold Tooling:

– Advanced Technology and Expertise: PTMS employs a team of skilled engineers and technicians who utilize cutting-edge software (e.g., MOLDFLOW for mold flow analysis) and CNC machining, EDM, and wire-cutting equipment to ensure precision. Their tooling processes adhere to strict quality control measures, from material selection to final mold testing.

– Diverse Industry Experience: PTMS specializes in plastic injection tooling for automotive, medical, and consumer electronics sectors. Whether producing complex automotive interior molds or sterile medical device tooling, they tailor solutions to unique client requirements, including compliance with ISO 9001 and medical industry standards.

– Comprehensive Services: From mold design and prototyping to production and after-sales support, PTMS offers turnkey services. Their expertise in injection mould tooling in China includes mold maintenance, repair, and spare parts supply, ensuring long-term reliability for clients’ production lines.

– Global Clientele and Reputation: PTMS serves customers across Europe, North America, and Asia, earning a reputation for on-time delivery, transparent communication, and molds that consistently meet performance expectations. Their commitment to quality has made them a go-to supplier for companies seeking reliable injection mold partners in China.

Conclusion

China’s injection mold tooling industry continues to set global benchmarks for precision, efficiency, and value. As manufacturers worldwide seek to optimize production, injection mold tooling suppliers in China like PTMS play a pivotal role in delivering innovative, cost-effective solutions. With expertise in plastic injection mold tooling, advanced technology, and a customer-centric approach, PTMS stands at the forefront of China’s injection mold tooling sector, empowering businesses to bring top-quality products to market faster and more efficiently.

Ready to elevate your manufacturing with top-tier injection mold tooling? Contact PTMS today to discuss your project needs and experience the excellence of China’s leading injection mold tooling supplier.