Injection Molded Parts: Complete Guide to Manufacturing and Applications

From the smartphone in your pocket to the dashboard in your car, injection molded parts surround us in virtually every aspect of modern life. This industrial manufacturing process produces approximately 30% of all plastic products globally, representing a market valued at over $250 billion as of 2022. Whether you’re a product designer, engineer, or business owner considering injection molding for your next project, understanding the intricacies of this manufacturing method is crucial for making informed decisions.

Injection molding has revolutionized how we manufacture plastic components, offering unmatched precision, repeatability, and cost-effectiveness for medium to high-volume production runs. This comprehensive guide will walk you through everything you need to know about injection molded parts, from the fundamental manufacturing process to advanced design considerations and real-world applications across industries.

What is Injection Molded Parts?

Injection molded parts are plastic components manufactured through the injection molding process, where molten plastic material is injected under high pressure into custom injection molds to create precise, repeatable parts. This manufacturing method transforms plastic resin pellets into finished components through a carefully controlled process of heating, injection, cooling, and ejection.

The most recognizable examples of injection molded parts include bottle caps, automotive dashboards, smartphone cases, LEGO bricks, and medical devices like syringes. These components share several key characteristics that make injection molding the preferred manufacturing process:

High Precision and Repeatability: Modern injection machines can achieve tolerances as tight as ±0.001mm, ensuring consistent quality across millions of parts. This level of precision makes injection molded plastic parts ideal for applications requiring exact fits and functional performance.

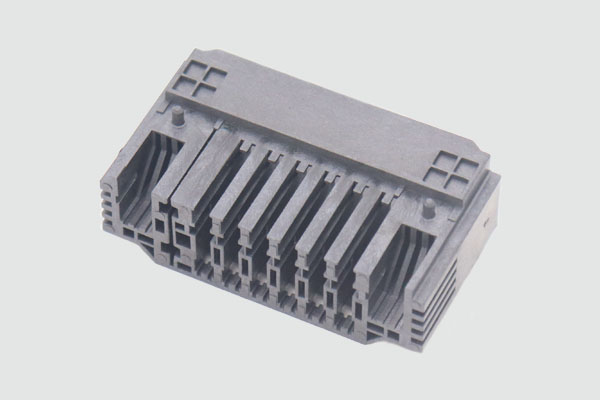

Complex Geometry Capabilities: The injection molding process can produce intricate shapes, undercuts, threads, and fine surface details that would be difficult or impossible to achieve with other manufacturing processes. This versatility allows designers to consolidate multiple components into single injection molded plastic parts, reducing assembly costs and potential failure points.

Material Versatility: Injection molded parts can be manufactured from an extensive range of plastic materials, including:

- Thermoplastic resins like ABS, polypropylene, and polyethylene for general-purpose applications

- Engineering plastics such as nylon, polycarbonate, and POM for high-performance requirements

- Specialty compounds including glass-filled resins, flame-retardant materials, and biocompatible grades

- Thermoplastic elastomer and thermoplastic polyurethane for flexible applications

The choice of plastic material directly impacts the final part’s mechanical properties, chemical resistance, temperature performance, and cosmetic appearance. This flexibility allows engineers to tailor injection molded parts to meet specific application requirements while maintaining cost-effectiveness.

Common Types and Applications of Injection Molded Parts

The versatility of plastic injection molding has made it indispensable across numerous industries, each with unique requirements for performance, aesthetics, and regulatory compliance. Understanding these applications helps illustrate the breadth and importance of injection molded plastic parts in modern industrial manufacturing.

Consumer Products

Consumer goods represent one of the largest segments for injection molded parts, where factors like cosmetic appearance, cost, and functionality drive design decisions. Common applications include:

- Toys and recreational products: LEGO bricks exemplify precision injection molding, with tolerances measured in micrometers to ensure perfect interlocking

- Kitchen utensils and appliances: From measuring cups to blender housings, these parts must withstand repeated use and dishwasher cycles

- Electronic device housings: Smartphone cases, remote controls, and computer peripherals require precise fits and electromagnetic interference shielding

- Packaging containers: Food storage containers, cosmetic packages, and pharmaceutical bottles demand chemical compatibility and barrier properties

Automotive Components

The automotive industry relies heavily on injection molding for both interior and exterior components, driven by requirements for weight reduction, cost control, and safety regulations. Key applications include:

- Interior trim panels: Dashboard components, door panels, and center consoles require Class A surface finishes and precise fits

- Exterior body panels: Bumper covers, grilles, and trim pieces must withstand weather exposure and impact resistance

- Under-hood components: Air intake manifolds, coolant reservoirs, and electrical housings need chemical resistance and temperature stability

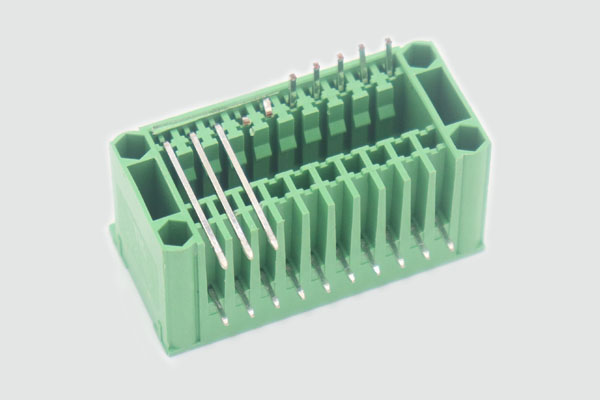

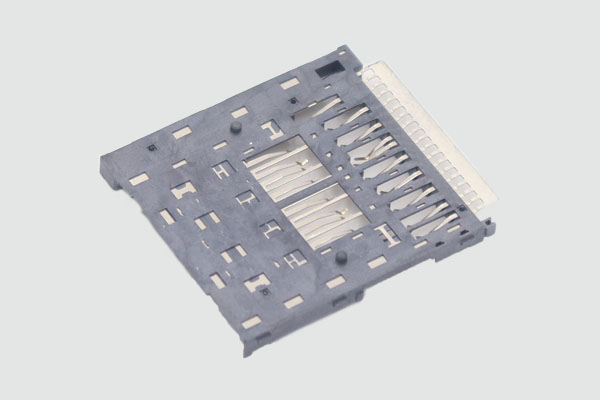

- Electrical connectors: These precision parts require tight tolerances and reliable electrical properties for vehicle safety systems

Medical Devices

Medical applications demand the highest levels of quality control, material traceability, and regulatory compliance. Common injection molded medical devices include:

- Disposable syringes: These precision parts require smooth operation, leak-proof sealing, and biocompatible materials

- Surgical instruments: Forceps, clamps, and specialized tools benefit from the design flexibility of injection molding

- Diagnostic equipment housings: Blood analyzers, imaging equipment, and monitoring devices require precise fits and easy sterilization

- Prosthetic components: Custom-molded parts can be tailored to individual patient needs while maintaining consistent quality

Industrial and Aerospace Applications

Industrial applications often prioritize durability, chemical resistance, and dimensional stability over aesthetics. Common parts include:

- Mechanical gears and bearings: Engineering plastics like nylon and POM provide excellent wear resistance and self-lubrication

- Electrical housings and enclosures: These components protect sensitive electronics from environmental hazards

- Custom brackets and fasteners: Injection molding allows for complex geometries that can replace multiple machined components

- Aerospace interior panels: Lightweight components with flame-retardant properties meet strict aviation safety requirements

The Injection Molding Manufacturing Process

Understanding the injection molding cycle is essential for anyone working with injection molded parts, as each step directly impacts final part quality, cycle time, and production costs. The manufacturing process follows four distinct phases that typically complete in 15-120 seconds, depending on part size and complexity.

Material Preparation and Feeding

The injection molding process begins with plastic resin pellets stored in a material hopper. These pellets, which may include recycled content or previously developed materials, are automatically fed into a heated chamber within the injection machine. Proper material handling prevents contamination and ensures consistent part quality.

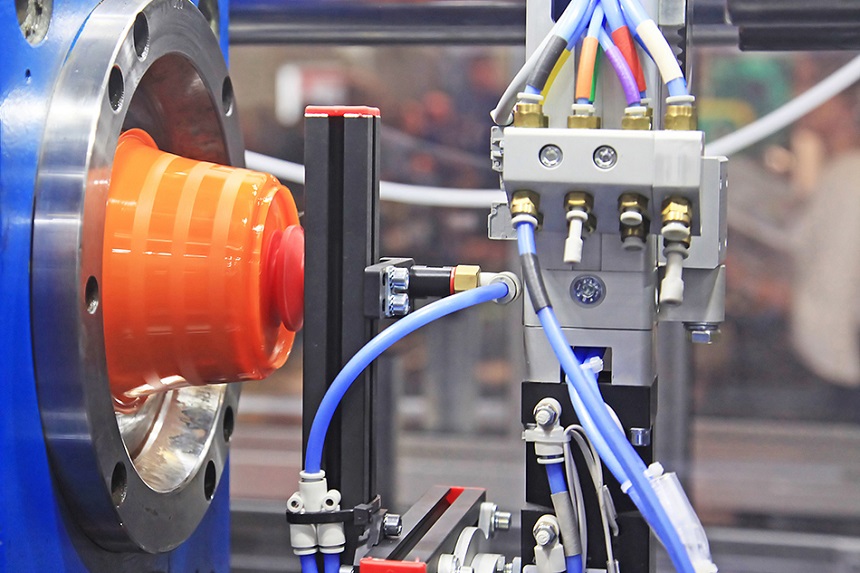

During this stage, the plastic material undergoes initial heating in the injection unit’s barrel, where a reciprocating screw both melts and mixes the resin. Temperature control is critical – insufficient heat results in incomplete melting, while excessive heat can cause material degradation or too much shear heat generation that leads to burning.

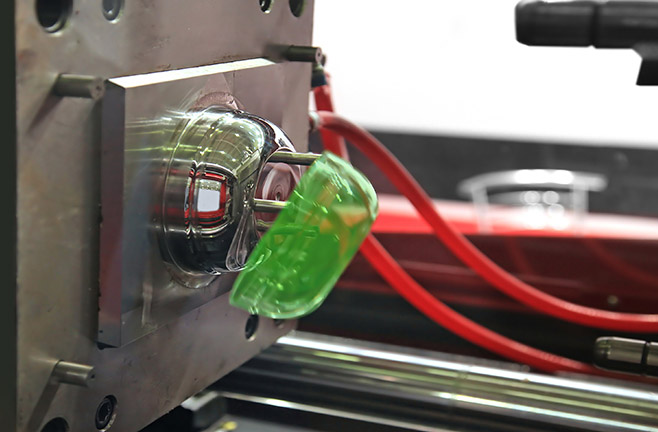

Injection Phase

Once the plastic material reaches the proper molten state, the injection ram forces the melted plastic through the injection unit into the mold cavity under high pressure, typically ranging from 100-150 MPa. The injection speed set during this phase affects both fill quality and final part properties.

The molten material flows through a carefully designed gate and runner system that distributes the plastic evenly throughout the mold cavity. Proper gate design ensures uniform filling while minimizing weld lines and air entrapment. The injection pressure must be sufficient to completely fill the mold while avoiding flashing or part wall contamination.

Cooling and Solidification

After injection, the molten plastic begins cooling within the temperature-controlled mold. This cooling phase often represents the longest portion of the injection molding cycle, as the part must solidify sufficiently for safe ejection. The cooling rate affects both dimensional accuracy and internal stress levels.

Molds typically incorporate cooling channels that circulate temperature-controlled fluid to maintain consistent cooling rates. Parts with uniform wall thickness cool more predictably, while thick sections may require extended cooling time or risk sink marks and internal voids. Fast heat removal is essential for maintaining short cycle times and preventing part distortion.

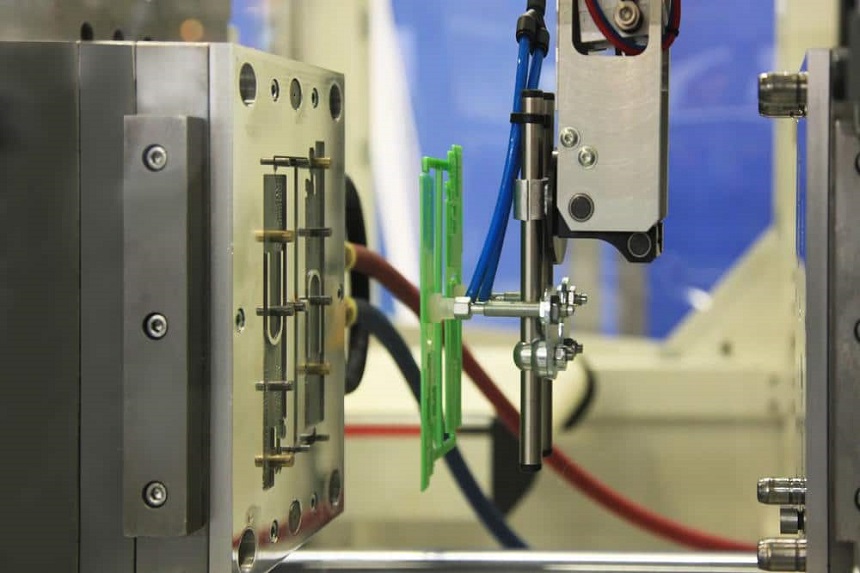

Ejection and Cycle Completion

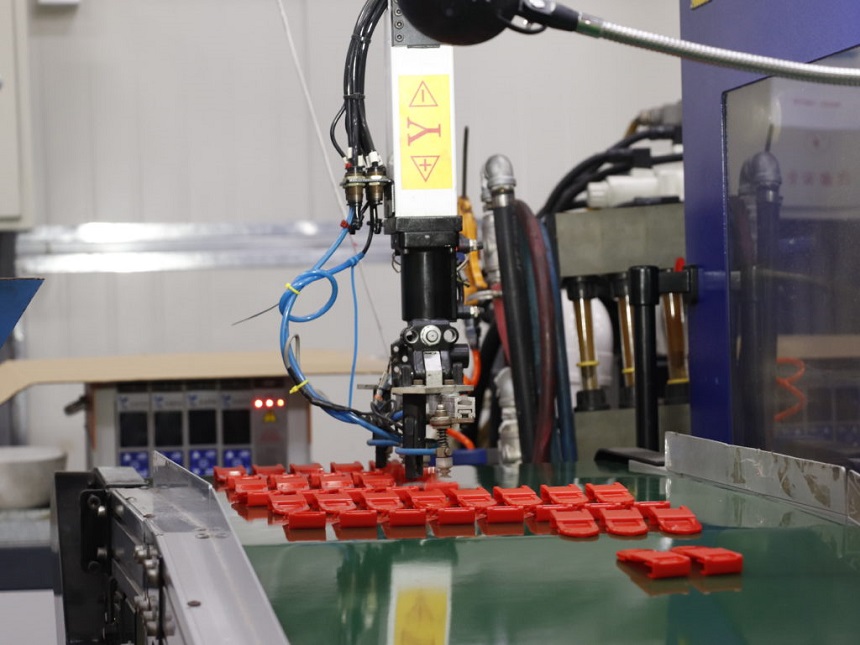

Once the plastic part has cooled sufficiently, the mold opens along the parting line, and ejector pins push the finished part from the mold cavity. Proper ejection requires adequate draft angles on all surfaces parallel to the mold opening direction – typically 1-2 degrees minimum.

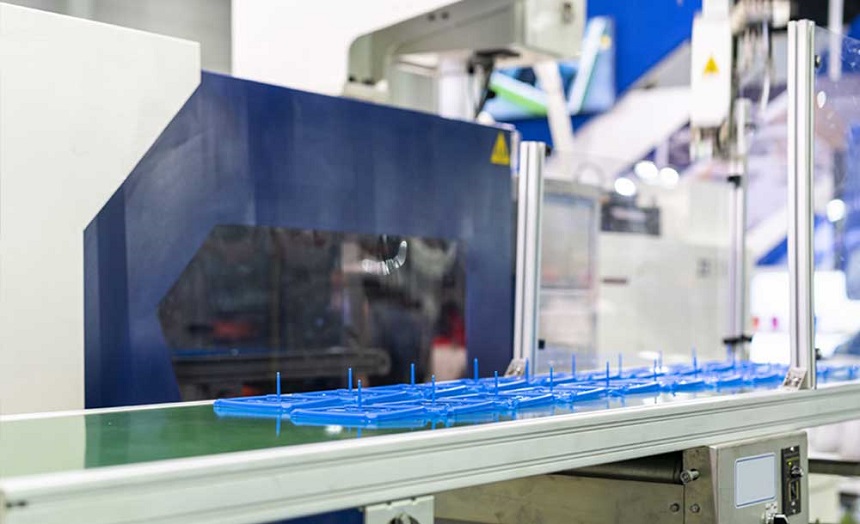

The ejected part may require secondary operations such as gate removal, deflashing, or assembly with other components. Automated systems can handle these operations for high-volume production, while lower volumes might require manual finishing.

Quality control checkpoints throughout the manufacturing process ensure dimensional accuracy, surface finish, and functional performance meet specifications. Statistical process control methods track key variables like cycle time, injection pressure, and part weight to maintain consistent quality.

Materials and Properties for Injection Molded Parts

Material selection represents one of the most critical decisions in developing injection molded parts, as the chosen plastic material directly determines the part’s mechanical properties, environmental resistance, processing requirements, and ultimate cost. With over 18,000 available plastic compounds, understanding material categories and selection criteria is essential for successful part design.

Thermoplastic Materials

Thermoplastics form the foundation of injection molding, offering the ability to be melted, molded, and recycled multiple times without significant degradation. These materials comprise the vast majority of injection molded plastic parts due to their processing flexibility and property range.

Commodity Thermoplastics provide cost-effective solutions for general-purpose applications:

- Polypropylene (PP): Excellent chemical resistance and fatigue resistance make it ideal for living hinges, containers, and automotive components

- High density polyethylene (HDPE) and low density polyethylene (LDPE): Outstanding impact resistance and chemical inertness suit packaging and chemical handling applications

- Polystyrene (PS): Low cost and excellent moldability make it popular for disposable items and packaging

- ABS (Acrylonitrile Butadiene Styrene): Good balance of strength, toughness, and processability for electronic housings and automotive trim

Engineering Thermoplastics offer superior performance for demanding applications:

- Nylon (Polyamide): High strength, excellent wear resistance, and chemical compatibility make it suitable for gears, bearings, and structural components

- Polycarbonate (PC): Outstanding impact resistance and optical clarity suit safety glazing and electronic housings

- Polyoxymethylene (POM): Excellent dimensional stability and low friction properties ideal for precision mechanical parts

Specialty and High-Performance Materials

Advanced applications often require specialized plastic materials with enhanced properties:

Glass-Filled Resins: Adding glass fiber reinforcement significantly increases strength and stiffness while reducing thermal expansion. These materials suit structural applications requiring dimensional stability under load and temperature variation.

Flame-Retardant Compounds: Applications in electronics, automotive, and aerospace often mandate specific flame resistance ratings. Various additive systems can achieve UL 94 ratings while maintaining other essential properties.

Biocompatible Grades: Medical device applications require materials tested and certified for biological safety. These specially formulated resins undergo extensive testing to ensure compatibility with human tissue and body fluids.

Conductive Plastics: Adding carbon fiber, metal particles, or conductive polymers creates materials suitable for electromagnetic interference shielding or static dissipation applications.

Material Selection Criteria

Successful material selection requires balancing multiple factors:

Mechanical Properties: Tensile strength, impact resistance, and fatigue performance must match application requirements. Typical hardness ranges vary significantly between materials, affecting wear resistance and feel.

Environmental Resistance: Chemical compatibility, UV resistance, and temperature performance determine material suitability for specific environments. Some applications require materials that maintain properties across wide temperature ranges.

Processing Considerations: Different materials require specific processing parameters, including melt temperatures, injection pressures, and cooling rates. Some materials are more sensitive to contaminated material or require precise moisture control.

Cost and Availability: Material cost often drives selection, but total cost must include processing considerations, cycle time impacts, and potential secondary operations. Some specialty materials have limited supplier networks affecting availability and pricing.

Sustainability: Increasing emphasis on environmental responsibility drives interest in recycled content, bio-based materials, and end-of-life recyclability. Many injection molded plastic parts now incorporate post-consumer recycled content without compromising performance.

Design Considerations for Injection Molded Parts

Successful injection molding begins with proper part design that considers both functional requirements and manufacturing constraints. Design for manufacturability principles can mean the difference between a cost-effective, high-quality part and an expensive, problematic production nightmare. Early collaboration between design engineers and molding experts prevents costly tooling modifications and ensures optimal part performance.

The fundamental principle underlying all injection molding design rules is the need for molten plastic resin to flow uniformly into the injection mold cavity, cool consistently, and release cleanly from the tooling surfaces. Violations of these principles typically result in defects such as sink marks, warpage, short shots, or difficult part removal.

Wall Thickness and Structural Design

Uniform wall thickness represents the most critical design consideration for injection molded parts. Maintaining consistent thickness promotes even cooling, minimizes internal stresses, and reduces cycle time while preventing common defects.

Optimal Wall Thickness Guidelines:

- General purpose parts: 2-4mm wall thickness provides good balance of strength and moldability

- Thin-wall applications: Specialized molding can achieve walls as thin as 0.5mm for electronics and packaging

- Thick sections: Walls exceeding 6mm risk sink marks and extended cooling times

- Thickness variation: Gradual transitions using 3:1 ratio prevents stress concentrations

Structural Design Elements:

Ribs provide structural reinforcement without increasing overall wall thickness. Proper rib design maintains 60% of the nominal wall thickness to prevent sink marks on opposite surfaces. Ribs should include adequate draft angles and generous radii at intersections to promote good flow and release.

Bosses facilitate attachment points for screws or insert while maintaining structural integrity. Like ribs, boss wall thickness should not exceed 60% of the surrounding wall to prevent cosmetic defects. Coring out thick bosses reduces material usage and improves cooling uniformity.

Material Shrinkage Considerations:

All thermoplastic materials shrink as they cool from molten to solid state, typically 0.5% to 2% depending on the specific resin and processing conditions. This material shrinkage must be compensated in the tooling design to achieve final dimensional targets. Non-uniform cooling caused by thickness variations leads to differential shrinkage and part warpage.

Draft Angles and Parting Lines

Draft angles facilitate easy part ejection from the injection mold while minimizing surface damage and reducing ejection forces. Insufficient draft can cause part distortion, surface scuffing, or tool damage during ejection.

Standard Draft Requirements:

- Smooth surfaces: 1-2 degrees minimum draft on all surfaces parallel to mold opening

- Textured surfaces: Additional draft of 1.5° per 0.001” texture depth

- Deep cavities: Increased draft requirements for higher aspect ratio features

- External vs. internal surfaces: Internal surfaces typically require slightly more draft due to shrinkage effects

Parting Line Placement Strategy:

The parting line where mold halves meet affects both part appearance and manufacturing cost. Strategic placement can minimize cosmetic impact on visible surfaces while simplifying tool construction. Complex parting lines increase tooling cost and may require additional mold actions.

Undercut features that prevent straight ejection require special consideration. Side actions, lifters, or hand-loaded inserts can accommodate undercuts but add significant tooling complexity and cost. Alternative design approaches often provide more cost-effective solutions.

Gate Design and Location

The gate and runner system controls how molten material flows into the injection mold cavity, directly affecting part quality, cycle time, and material usage. Proper gate design ensures uniform mold filling while minimizing cosmetic defects and material waste.

Common Gate Types and Applications:

- Edge gates: Located on the part perimeter, offering easy trimming and minimal cosmetic impact

- Sub gates: Positioned below the parting line for automatic trimming during ejection

- Hot tip gates: Direct injection minimizes runner waste for high-volume production

- Fan gates: Wide opening distributes flow for large, flat parts requiring uniform filling

Gate Sizing and Location Strategy:

Gate size must balance fill time against shear heating. Undersized gates cause excessive pressure drops and material degradation, while oversized gates extend cooling time and create cosmetic defects. The gate temperature during injection affects local part quality and cycle time.

Strategic gate placement minimizes weld lines where flow fronts meet, ensuring optimal mechanical properties and cosmetic appearance. Multiple gates may be necessary for large or complex parts, requiring careful balancing to achieve uniform filling patterns.

The new shot nozzle temperature and injection speed set affect gate freeze-off timing, which controls when the gate seals and injection pressure can no longer feed the part. This timing is critical for controlling part dimensions and minimizing sink marks in thick sections.

Quality Control and Testing Methods

Quality control in injection molding encompasses both in-process monitoring and finished part inspection to ensure consistent dimensional accuracy, mechanical properties, and aesthetic standards. Modern quality systems integrate real-time process monitoring with statistical analysis to maintain tight control over part-to-part variation while minimizing defective production.

Effective quality control begins with first article inspection when a new mold or process is established. This comprehensive evaluation validates that the injection molding process produces parts meeting all specifications before full production begins. Any deviations identified during first article inspection require process adjustments or design modifications to prevent ongoing quality issues.

In-Process Monitoring and Control

Modern injection machines incorporate sophisticated monitoring systems that track critical process variables in real-time. Key parameters include injection pressure, shot nozzle temperature, cycle time, and part weight. Deviations from established control limits trigger automatic adjustments or production stops to prevent defective parts.

Critical Process Variables:

- Injection pressure monitoring detects mold filling irregularities that could indicate material flow problems or tool wear

- Temperature control throughout the heating unit and tooling surfaces ensures consistent material properties

- Cycle time variation often indicates cooling issues or ejection problems requiring attention

- Part weight consistency indicates proper mold filling and material metering

Automated Inspection Systems:

Machine vision systems can inspect every part for dimensional accuracy, surface defects, and completeness. These systems detect flash, short shots, contamination, and cosmetic defects at production speeds, removing defective parts before they enter the supply chain.

More advanced inspection techniques include industrial CT scanning for detecting internal defects, voids, and material distribution in complex parts. This non-destructive testing method is particularly valuable for medical devices and aerospace components where internal quality is critical.

Statistical Process Control Methods

Statistical process control (SPC) methods track process variation over time, enabling proactive adjustments before parts fall outside specification limits. Control charts for key dimensions, process parameters, and defect rates provide early warning of developing problems.

Key SPC Applications:

- Dimensional control charts track critical part dimensions against specification limits

- Process capability studies quantify the process’s ability to consistently produce parts within specification

- Correlation analysis identifies relationships between process variables and part quality

- Trend analysis detects gradual process shifts requiring preventive maintenance

Material Traceability and Documentation

Regulatory requirements in medical, automotive, and aerospace applications mandate complete material traceability from raw material receipt through final part shipment. This documentation enables rapid response to material quality issues and supports recall procedures when necessary.

Material certification documents verify that plastic material meets specification requirements for mechanical properties, chemical composition, and regulatory compliance. Lot tracking systems maintain records linking specific material lots to production runs and finished parts.

Heat treated tool surfaces and pre hardened steel molds require periodic inspection to ensure continued dimensional accuracy and surface finish quality. Tool maintenance records support predictive maintenance programs that minimize unplanned downtime.

Industry Applications and Case Studies

Different industries place unique demands on injection molded parts, requiring specialized materials, processes, and quality systems. Understanding these industry-specific requirements helps illustrate how injection molding adapts to meet diverse performance, regulatory, and economic constraints.

Automotive Industry Excellence

The automotive industry represents one of the most demanding applications for injection molded parts, requiring compliance with strict quality standards, cost targets, and safety regulations. Automotive suppliers must achieve PPAP (Production Part Approval Process) approval, demonstrating capability to consistently produce parts meeting all specifications.

Performance Requirements: Automotive injection molded parts must withstand extreme temperature cycling, chemical exposure, and mechanical stress while maintaining dimensional stability and appearance. Interior components require low VOC emissions and resistance to UV degradation, while under-hood parts need thermal stability and chemical resistance to automotive fluids.

Quality Standards: Automotive parts typically require tolerances of ±0.001mm for critical dimensions, with comprehensive dimensional inspection using coordinate measuring machines. Statistical process control monitors key characteristics, with capability indices (Cpk) typically exceeding 1.33 for critical features.

Case Study – Dashboard Assembly: A major automotive manufacturer consolidated a 15-component dashboard assembly into three injection molded parts, reducing assembly time by 40% while improving fit and finish. The design incorporated living hinges, snap fits, and integrated mounting features, demonstrating the design flexibility possible with injection molding. Material selection included flame-retardant ABS with specific surface texture requirements matching the vehicle’s interior design theme.

Medical Device Manufacturing

Medical device applications demand the highest levels of quality control, material traceability, and regulatory compliance. FDA regulations require comprehensive validation of materials, processes, and finished devices, with complete documentation maintained throughout the product lifecycle.

Regulatory Compliance: Medical injection molded parts must use FDA-approved materials with appropriate biocompatibility testing for their intended use. Process validation demonstrates that the manufacturing process consistently produces devices meeting all specifications, with ongoing monitoring to ensure continued compliance.

Cleanroom Processing: Many medical devices require manufacture in controlled environments to prevent contamination. Class 7 or Class 8 cleanrooms maintain strict limits on airborne particles, with personnel, materials, and equipment following rigorous contamination control procedures.

Case Study – Disposable Syringe Production: A leading medical device manufacturer produces over 100 million disposable syringes annually using a specialized injection molding process. The three-component design (barrel, plunger, and needle hub) requires precise dimensional control to ensure smooth operation and leak-proof sealing. Automated assembly and packaging systems maintain sterility while achieving cycle times under 10 seconds per complete syringe.

Consumer Electronics Precision

Consumer electronics demand exceptional dimensional accuracy and surface finish quality to ensure proper fit and function in increasingly compact devices. Electromagnetic interference shielding and thermal management often drive material selection for electronic housings.

Design Challenges: Modern electronic devices require injection molded parts with complex geometries, thin walls, and precise fits. Multiple snap-fit features, integrated heat sinks, and EMI shielding requirements push the limits of conventional process description and tooling design.

Surface Finish Requirements: Class A surface finishes on consumer devices require specialized tooling materials and processing techniques. Tool surface preparation, gate design, and processing parameters all affect final appearance, with defects like weld lines, sink marks, or gate marks potentially causing cosmetic rejection.

Aerospace and Defense Applications

Aerospace applications require injection molded parts meeting stringent safety, performance, and traceability requirements. Materials must often meet specific flame resistance, smoke generation, and toxicity standards while maintaining mechanical properties across wide temperature ranges.

Material Qualification: Aerospace materials undergo extensive testing and qualification processes before approval for flight applications. This includes mechanical property testing, flammability testing, and long-term aging studies to ensure consistent performance throughout the aircraft’s service life.

Quality Assurance: 100% inspection and testing of critical aerospace components ensures airworthiness and passenger safety. Non-destructive testing methods detect internal defects, while material certification provides complete traceability to raw material sources.

Advantages and Limitations of Injection Molded Parts

Understanding both the capabilities and constraints of injection molding helps designers and engineers make informed decisions about when this manufacturing process provides optimal solutions. While injection molding offers unmatched advantages for many applications, recognizing its limitations prevents costly design mistakes and unrealistic expectations.

Key Advantages of Injection Molding

High Production Efficiency and Scalability: Injection molding excels at high volume production, with modern machines capable of producing hundreds to thousands of parts per day per mold. Once the injection molding cycle is optimized, the process runs with minimal operator intervention, making it ideal for lights-out manufacturing operations.

Cycle times ranging from 15 seconds for small parts to 2 minutes for large components enable rapid part accumulation. Multi-cavity molds multiply this advantage, with some tools producing 96 identical parts per cycle for small components like bottle caps or electrical connectors.

Exceptional Precision and Repeatability: Modern injection molding achieves tolerances as tight as ±0.001mm when properly designed and controlled. This precision remains consistent across millions of parts, making injection molding ideal for applications requiring exact fits and functional performance.

The manufacturing process inherently produces parts with consistent wall thickness, surface finish, and mechanical properties. This repeatability is crucial for automated assembly operations and ensures predictable product performance across large production volumes.

Design Flexibility and Complexity: Injection molding can produce intricate geometries that would be difficult or impossible with other manufacturing processes. Complex internal passages, living hinges, snap-fit features, and integrated assembly details can be molded as single parts, reducing assembly costs and potential failure points.

Insert molding capabilities allow integration of metal components, electronic devices, or other materials during the molding process. This technique creates hybrid parts combining the advantages of different materials while maintaining the precision and efficiency of injection molding.

Material Versatility: The availability of over 18,000 plastic compounds provides designers with materials tailored to specific application requirements. From low-cost commodity plastics to high-performance engineering materials, injection molding accommodates an extremely broad range of mechanical, thermal, and chemical property requirements.

Recycled content and bio-based materials support sustainability initiatives while maintaining part performance. Many thermoplastic materials can be reprocessed multiple times, supporting circular economy principles.

Significant Limitations and Constraints

High Initial Investment Requirements: Tooling costs represent the most significant barrier to injection molding adoption, ranging from $5,000 for simple prototype molds to over $500,000 for complex, high-cavitation production tools. These upfront costs must be amortized across production volumes, making injection molding uneconomical for low-volume applications.

Custom mold fabrication typically requires 6-12 weeks for design, manufacturing, and debugging, extending time-to-market compared to other manufacturing methods. Rush tooling programs can reduce lead times but at significantly increased cost.

Design Change Inflexibility: Once injection molds are manufactured, design changes become expensive and time-consuming. Adding material is generally possible but difficult, while removing material may require complete tool rebuilding. This inflexibility requires thorough design validation before committing to tooling.

The conventional process description requires designers to “design for molding” from the project outset, considering wall thickness uniformity, draft angles, and gate locations early in the design process. Retrofitting these requirements into existing designs often proves costly or impossible.

Processing Limitations and Constraints: Certain geometric features remain challenging or impossible to mold. Deep undercuts, internal threads, and enclosed cavities may require expensive mold actions or alternative manufacturing methods. Extremely thick sections risk sink marks and extended cooling times that impact production efficiency.

Material limitations exclude most thermoset composites, metals, and ceramics from conventional injection molding. While specialized processes like metal injection molding exist, they require different equipment and expertise.

Quality Control Challenges: Injection molding defects can be subtle and difficult to detect, particularly internal voids, stress concentrations, or contamination issues. Some defects only manifest during field use, requiring comprehensive testing and validation programs.

Process sensitivity means that small variations in material properties, ambient conditions, or machine settings can affect part quality. Maintaining consistent quality requires skilled operators, comprehensive monitoring systems, and robust process control procedures.

Environmental and Sustainability Concerns: The conventional process description for injection molding requires significant energy consumption for heating, melting, and cooling plastic materials. Runner waste and setup parts represent material inefficiency, though hot runner systems and recycling programs mitigate these concerns.

Limited material recyclability for certain specialty compounds and thermoset materials creates end-of-life disposal challenges. However, the long service life and design efficiency of many injection molded parts often offset these environmental concerns.

Strategic Decision Framework

Injection molding provides optimal solutions when:

- Production volumes exceed 10,000 parts annually

- Part complexity benefits from molding rather than assembly

- Tight tolerances and consistent quality are critical

- Material properties match thermoplastic capabilities

- Design requirements are well-defined and stable

Alternative manufacturing methods may be preferable when:

- Production volumes are below 1,000 parts annually

- Frequent design changes are anticipated

- Material requirements exceed thermoplastic capabilities

- Tooling investment cannot be justified economically

- Time-to-market is more critical than unit cost

Understanding these trade-offs enables informed decisions about when injection molding provides the optimal balance of cost, quality, performance, and time-to-market for specific applications. Successful implementation requires early collaboration between design teams, material suppliers, and molding experts to optimize the entire system for manufacturing excellence.

Manufacturing plastic parts through injection molding remains one of the most versatile and cost-effective methods for high-volume production. Whether you’re developing automotive components, medical devices, or consumer products, understanding the capabilities and limitations of this manufacturing process enables informed decisions that balance performance, cost, and quality requirements. Consider consulting with experienced injection molding professionals early in your design process to optimize your parts for manufacturing success.

Recommend the Leading injection Molded Parts Manufacturer in China – PTMS

Established in 2002 and ISO 9001:2008-certified, PTMS brings decades of expertise to injection molded part production, serving industry leaders across sectors while maintaining rigorous quality standards. Our extensive portfolio of injection molded parts has grown exponentially, driven by a loyal and expanding customer base, and the dedication of our professional team.

As a leader in the field, PTMS delivers superior quality and efficiency, with each part engineered and manufactured to meet the unique requirements of individual projects. We specialize in developing plastic molded components using engineering-grade resins, ensuring optimal form and functionality for diverse applications. Whether for automotive, industrial, aerospace, or other sectors, we provide high-quality, innovative solutions tailored to specific needs.

Our production capabilities cover a wide range of specifications: part sizes from 2mm×5mm×2mm to 1000mm×1000mm×300mm, weights from 0.35g to 2000g, and precision up to ±0.01mm (with ±0.001mm available for special requests). We also offer fully customized parts based on customer designs, expanding our product gallery to include holders, covers, handles, brackets, cases, and more—all made possible by our team’s consistent efforts.

PTMS provides state-of-the-art plastic injection molding services, leveraging cutting-edge machinery to produce high-quality parts that drive business success. We prioritize personalized solutions, crafting application-specific components to match unique customer specifications. From concept to completion, our experienced specialists offer expert guidance to ensure parts exceed expectations. Choose PTMS for reliable, top-quality plastic injection molding products and solutions.