Plastic Injection Mold Maker in China: What Global Buyers Need to Know?

Choosing a reliable plastic injection mold maker in China is one of the most important decisions for any company producing plastic injection components. Whether the project involves consumer electronics, automotive parts, medical housings, industrial components, or custom prototypes, the quality of the mold directly determines the quality of the final product. Many international buyers ask similar questions before selecting an injection mold maker, and this article provides a comprehensive, experience‑driven guide to help you make informed decisions.

This article explores the essential capabilities of a professional injection mold maker, the standards used in China, the engineering workflow, the equipment required for precision tooling, and the key questions global customers frequently ask. It also explains how to evaluate mold quality, how to communicate effectively with a Chinese mold supplier, and how to ensure long‑term reliability for high‑volume production. Throughout the article, the keywords injection mold maker, plastic injection mold maker in China, and injection mold maker China are naturally integrated to support SEO while maintaining readability.

Understanding the Role of a Professional Injection Mold Maker

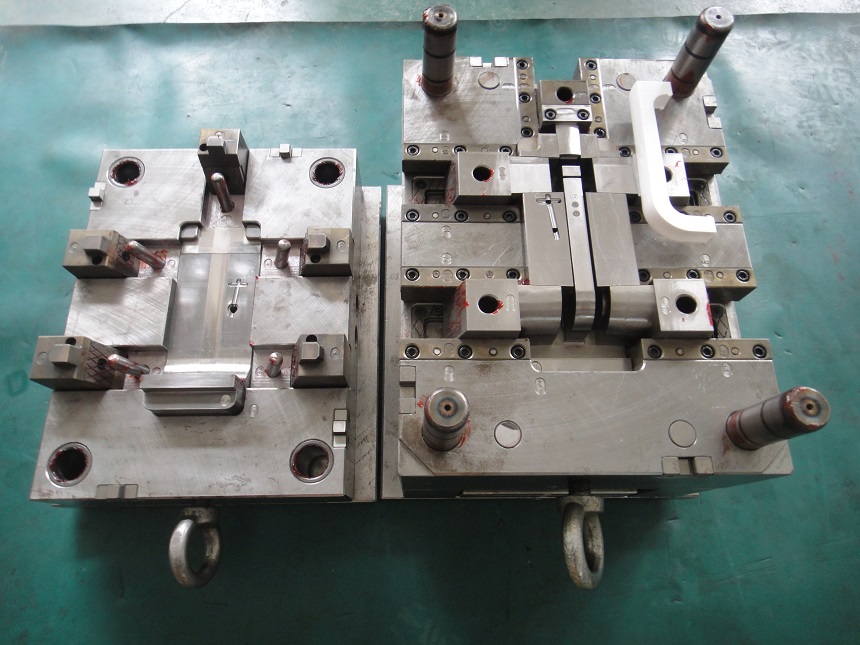

A plastic injection mold maker in China is responsible for transforming 2D or 3D product designs into high‑precision steel molds capable of producing millions of plastic parts. The mold maker must combine engineering expertise, advanced machinery, and strict quality control to ensure the mold performs consistently throughout its lifecycle.

Key responsibilities include:

– Interpreting 2D/3D product files and identifying manufacturability issues

– Designing the mold structure, cooling system, gating system, and ejection system

– Selecting the correct steel grade based on part volume and material

– Operating CNC, EDM, wire cutting, and grinding machines

– Ensuring dimensional accuracy and surface finish

– Conducting mold trials and optimizing performance

– Providing long‑term maintenance and support

A skilled injection mold maker in China must not only build the mold but also understand how the mold will behave in real production environments.

Why Many Global Companies Choose a Plastic Injection Mold Maker in China?

China has become a global hub for injection mold manufacturing due to its combination of engineering expertise, advanced equipment, and competitive pricing. Over the past two decades, Chinese mold makers have significantly improved their technical capabilities, making them trusted partners for companies in North America, Europe, Australia, and Asia.

Reasons international buyers choose China include:

– Strong engineering talent with 10–20 years of tooling experience

– Advanced CNC, EDM, wire cutting, and milling equipment

– Ability to meet international standards such as HASCO, DME, JIS, and LKM

– Faster lead times compared to many Western suppliers

– Competitive pricing without compromising quality

– Experience with complex mold types such as multi‑cavity, hot runner, and unscrewing molds

A professional plastic injection mold maker in China can deliver world‑class tooling at a fraction of the cost, making it a preferred choice for companies seeking both quality and efficiency.

Capabilities You Should Expect from a High‑Level Injection Mold Maker

When evaluating an injection mold maker in China, it is essential to understand the capabilities that differentiate a professional mold shop from an average one. The following capabilities are considered essential for high‑precision tooling.

Engineering and design capabilities:

– Ability to analyze 2D/3D files in formats such as DWG, IGS, X_T, and STP

– Mold flow analysis to predict filling, cooling, and warpage

– Experience with complex part geometries

– Knowledge of international mold standards

– Ability to propose design improvements for manufacturability

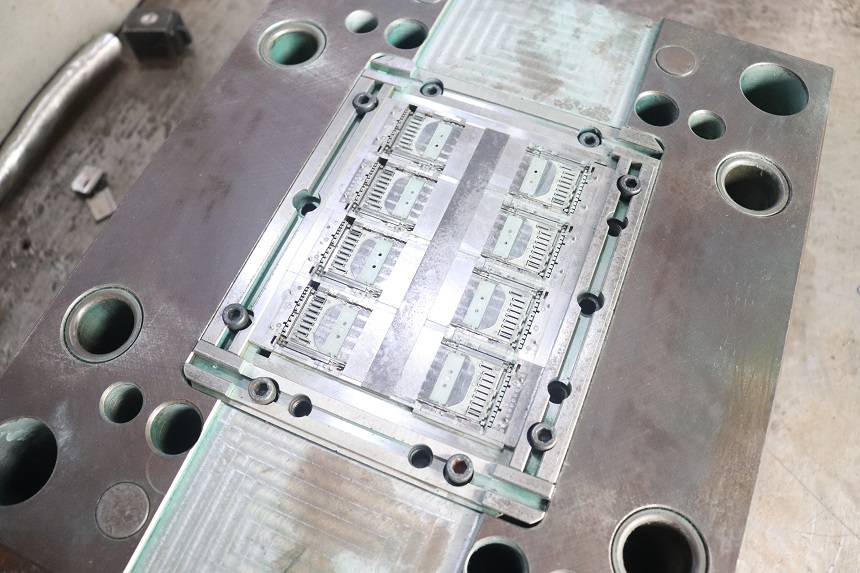

Manufacturing capabilities:

– CNC machining for high‑precision steel cutting

– EDM and mirror EDM for fine details and deep ribs

– Wire cutting for accurate mold inserts

– Grinding and polishing for surface finish

– Hot runner and cold runner system integration

Quality control capabilities:

– Dimensional inspection using CMM

– Hardness testing for steel verification

– Mold trial and sample evaluation

– Lifetime tracking and maintenance planning

A reliable injection mold maker must combine all three categories to deliver consistent results.

Common Questions Customers Ask a Plastic Injection Mold Maker in China

International customers often have similar concerns when working with a mold maker for the first time. Addressing these questions helps build trust and ensures smooth project execution.

Typical questions include:

– How long does it take to build a mold?

– What steel materials do you use for high‑volume production?

– Can you meet international mold standards?

– How do you ensure dimensional accuracy?

– What is included in the mold quotation?

– How many mold trials are provided?

– Can you support both prototype and mass‑production molds?

– How do you handle communication and project updates?

A professional injection mold maker in China should provide clear, detailed answers to all of these questions.

How a Mold Project Typically Progresses

A well‑structured workflow is essential for delivering a high‑quality mold. The process usually follows several key stages, each requiring technical expertise and close communication.

The typical workflow includes:

– Reviewing customer drawings and identifying potential issues

– Providing a detailed quotation with steel type, mold type, and lead time

– Creating the mold design and submitting it for customer approval

– Beginning steel machining using CNC, EDM, and wire cutting

– Assembling the mold and performing initial quality checks

– Conducting mold trials and sending sample parts to the customer

– Adjusting the mold based on feedback

– Finalizing the mold and preparing it for shipment

This structured approach ensures the mold meets all performance requirements before delivery.

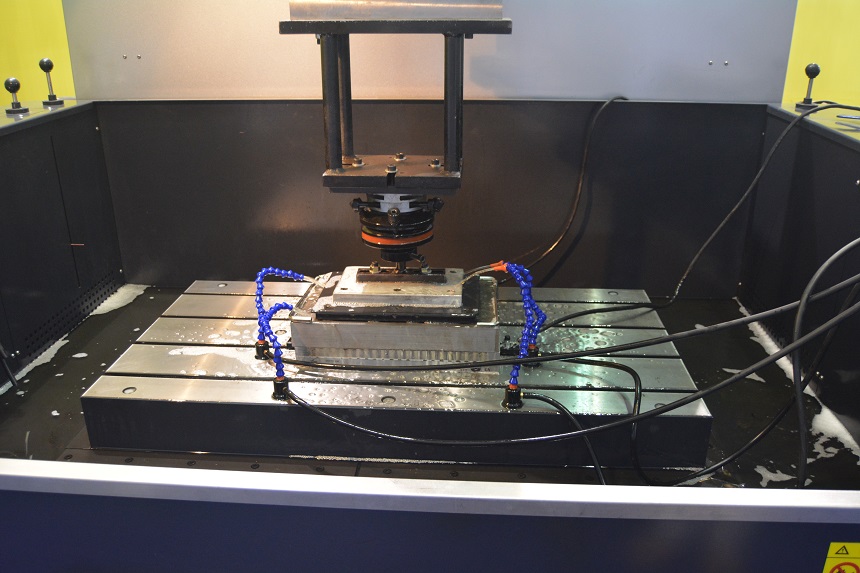

Why Equipment Matters When Choosing an Injection Mold Maker?

The quality of a mold is directly related to the equipment used to manufacture it. A professional plastic injection mold maker in China typically operates a wide range of machines to ensure precision and efficiency.

Essential equipment includes:

– CNC machining centers for accurate steel cutting

– Wire cutting machines for precise insert shaping

– Slow wire cutting machines for high‑tolerance components

– EDM and mirror EDM machines for deep ribs and fine details

– Milling machines for general shaping

– Grinding machines for surface accuracy

– Polishing machines for optical‑grade finishes

A mold maker with advanced equipment can achieve tighter tolerances, better surface finishes, and longer mold life.

Standards Used by a Professional Injection Mold Maker in China

To meet global expectations, Chinese mold makers often follow internationally recognized standards. These standards ensure compatibility with molding machines and maintenance systems used worldwide.

Common standards include:

– HASCO

– DME

– JIS

– LKM

– Enterprise‑specific standards based on customer requirements

Using standardized components improves mold reliability and simplifies maintenance for overseas customers.

How to Evaluate the Quality of a Mold from an Injection Mold Maker in China?

Evaluating mold quality is one of the most important steps for global buyers. A mold may look perfect on the outside, but its internal structure, steel hardness, cooling efficiency, and dimensional accuracy determine long‑term performance. A professional plastic injection mold maker in China should provide transparent quality documentation and measurable data.

Key evaluation points include:

– Steel certification from trusted suppliers

– Dimensional inspection reports

– Mold flow analysis results

– Cooling channel layout and efficiency

– Surface finish quality

– Mold lifetime estimation

– Sample part measurements

– Smooth ejection and stable cycle time

Customers should request these documents before approving final shipment.

How Communication Works with a Professional injection mold maker in China?

Clear communication is essential for successful mold development. Many international customers are worry about time zone differences, language barriers, and project updates. A reliable injection mold maker in China typically has a dedicated project management team to ensure smooth communication.

Typical communication practices include:

– Weekly progress reports with photos and machining updates

– Mold design approval before steel cutting

– Immediate notification of design challenges

– Video calls for complex engineering discussions

– Mold trial videos and sample part measurements

– Transparent lead‑time tracking

This structured communication helps avoid misunderstandings and ensures the mold meets all expectations.

Comparison Table: Local Mold Maker vs. Plastic Injection Mold Maker in China

Many companies compare domestic mold makers with Chinese suppliers. The table below summarizes the most common differences based on global customer feedback.

| Criteria | Local Mold Maker |

Plastic Injection Mold Maker in China |

| Cost | Higher | More competitive |

| Lead Time | Moderate | Faster in most cases |

| Engineering Experience | Strong | Strong, often 10–20 years |

| Equipment Level | Advanced | Advanced and continuously upgraded |

| Standards | Local standards | HASCO, DME, JIS, LKM |

| Communication | Same time zone | Managed through structured updates |

| Mold Types | Standard molds | Standard + complex molds |

| After‑Sales Support | Local service | Remote support + documentation |

| Value for Money | Good | Excellent |

This comparison shows why many global companies choose an injection mold maker China for both prototype and mass‑production molds.

Case Study: How a Global Manufacturer Improved Production with a Chinese Mold Maker?

A global electronics manufacturer needed a multi‑cavity mold for a high‑volume consumer product. Their previous mold suffered from warpage, slow cycle time, and inconsistent part dimensions. They approached a professional plastic injection mold maker in China to redesign and rebuild the mold.

The project included:

– Reviewing the original mold design

– Conducting mold flow analysis to identify filling issues

– Redesigning the cooling system for faster cycle time

– Improving steel hardness for longer mold life

– Adding optimized venting to reduce defects

Results achieved:

– Cycle time reduced by 18%

– Part warpage reduced by 35%

– Mold lifetime increased significantly

– Scrap rate dropped to below 1%

– Production efficiency improved across all shifts

This case demonstrates how a skilled injection mold maker can solve complex manufacturing challenges and deliver measurable improvements.

Client Testimonial

A long‑term customer from the industrial equipment sector shared the following feedback after receiving multiple molds from a plastic injection mold maker in China:

“We have worked with several mold suppliers over the years, but the engineering expertise and communication from this team exceeded our expectations. Their ability to analyze our 3D files, identify potential issues, and deliver molds that run smoothly from the first trial has saved us significant time and cost. The molds have been reliable, durable, and consistent across high‑volume production.”

How to Ensure Long‑Term Mold Performance

A high‑quality mold should last for hundreds of thousands or even millions of cycles. To achieve this, both the mold maker and the customer must follow proper maintenance practices.

Recommended steps include:

– Regular lubrication of moving components

– Monitoring mold temperature during production

– Cleaning the mold after each production run

– Inspecting ejector pins and slides

– Checking for wear on gates and runners

– Scheduling preventive maintenance based on cycle count

A professional mold maker provides maintenance guidelines to help customers maximize mold life.

Why Experience Matters When Choosing an Injection Mold Maker?

Experience is one of the strongest indicators of reliability. A mold maker with 10–20 years of experience has likely handled thousands of projects across multiple industries. This experience allows them to anticipate challenges, optimize designs, and deliver molds that perform consistently.

Benefits of working with an experienced mold maker include:

– Faster problem‑solving

– Better understanding of material behavior

– More accurate mold design

– Higher success rate during mold trials

– Reduced risk of costly modifications

– Experience directly translates into smoother production and lower long‑term costs.

How to Choose the Right Plastic Injection Mold Maker in China?

Selecting the right supplier requires careful evaluation. Customers should consider technical capability, communication style, equipment level, and long‑term reliability.

Key selection criteria include:

– Engineering expertise and mold design capability

– Experience with your industry

– Quality control processes

– Equipment and machining accuracy

– Ability to meet international standards

– Transparent project management

– Proven track record with complex molds

– Clear warranty and after‑sales support

A reliable injection mold maker in China should meet all of these criteria.

Final Recommendation: Why PTMS is the Leading Plastic Injection Mold Maker in China?

For companies seeking a reliable, experienced, and highly capable plastic injection mold maker in China, PTMS stands out as a trusted partner. With decades of experience, advanced equipment, and a professional engineering team, PTMS consistently delivers high‑precision molds for global customers.

Reasons PTMS is recommended:

– Over 20+ years of mold‑making experience

– Skilled engineers with 8–20 years of expertise

– Advanced CNC, EDM, wire cutting, and grinding equipment

– Ability to meet HASCO, DME, JIS, and LKM standards

– Strong project management and communication

– Proven success with complex mold types

– Commitment to quality, precision, and long‑term reliability

PTMS is a dependable injection mold maker in China capable of supporting both small and large‑scale projects with consistent excellence. Know more about plastic injection mold maker in China – PTMS.

Authoritative Sources Supporting Mold Manufacturing Best Practices

MIT Department of Mechanical Engineering – Injection molding fundamentals

https://meche.mit.edu

U.S. National Institute of Standards and Technology (NIST.gov) – Manufacturing standards and precision engineering

https://www.nist.gov

University of Wisconsin–Madison Engineering – Polymer processing and mold design research

https://engineering.wisc.edu

U.S. Department of Energy (Energy.gov) – Industrial efficiency and cooling system optimization

https://www.energy.gov