Plastic Injection Mold Tooling in China: PTMS Leads the Way in Precision and Innovation

China has solidified its position as a global hub for injection mold tooling, with manufacturers renowned for combining technical expertise, cost efficiency, and scalable production. At the forefront of this industry is PTMS, a leading injection mold tooling China manufacturer that sets benchmarks for quality and innovation in plastic injection mold tooling. This article delves into the significance of injection mold in China capabilities and why PTMS is the preferred partner for global businesses.

The Critical Role of Injection Mold Tooling in Manufacturing

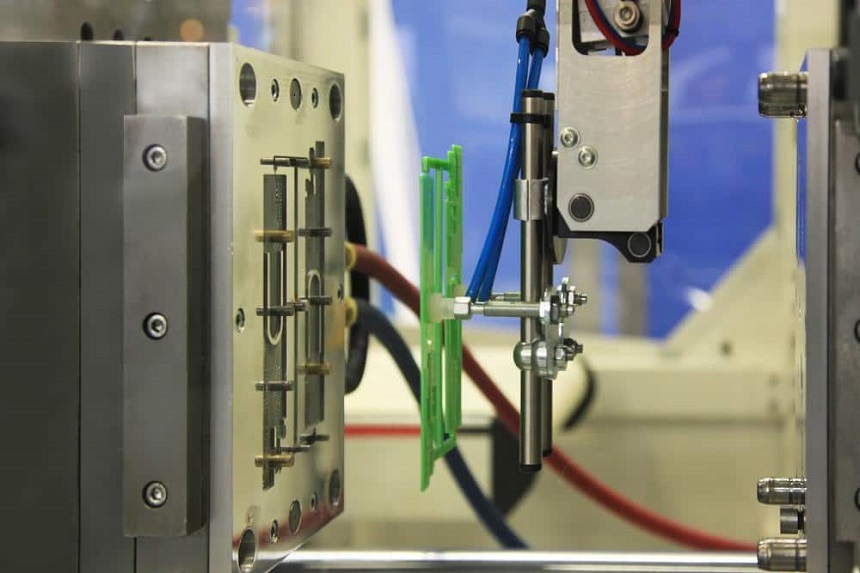

Injection mold tooling forms the backbone of plastic products production, enabling the creation of intricate, high-precision components across industries such as automotive, electronics, medical devices, and consumer goods. A well-engineered mold determines the final product’s accuracy, surface finish, and durability. Plastic injection mold tooling involves designing and fabricating molds with precision cavities, cooling systems, and ejection mechanisms, often using advanced materials like hardened steel (e.g., H13, S136) or ceramic composites for enhanced wear resistance and longevity.

In China, injection mould tooling manufacturers leverage cutting-edge technologies such as 3D design, computer-aided engineering (CAE) simulation, and high-speed machining to optimize mold performance. This ensures faster production cycles, reduced defects, and compatibility with diverse plastic materials, from standard polymers to high-performance resins like PEEK and LCP.

Why Choose Injection Mold Tooling in China?

Injection mold China has gained global recognition for several key advantages:

– Technical Prowess: Chinese manufacturers excel in producing complex molds, including multi-cavity, hot-runner, and stack molds, catering to high-volume production needs.

– Cost Efficiency: Economies of scale and advanced automation allow plastic injection tooling in China to offer competitive pricing without compromising quality.

– Rapid Turnaround: Streamlined workflows and integrated supply chains enable faster mold development, from prototyping to mass production.

Among these, PTMS stands out as a leader, combining these strengths with a focus on innovation and customer collaboration.

TMS: Leading Injection Mold Tooling Manufacturer in China

PTMS has established itself as a premier Injection mould tooling China manufacturer, trusted by global clients for its commitment to precision, reliability, and tailored solutions. Here’s why PTMS is the industry benchmark:

1. State-of-the-Art Infrastructure

PTMS operates advanced facilities equipped with high-precision CNC machining centers, EDM/wire-cut machines, and 3D metrology tools. This infrastructure ensures mold tolerances as tight as ±0.001mm, critical for industries like medical and aerospace.

2. Expertise in Diverse Tooling Solutions

From plastic injection mold tooling for micro-components to large-scale automotive molds, PTMS handles projects of all sizes. Their expertise includes:

– Custom Mold Design: Collaborating with clients to optimize part geometry, cooling channels, and gate placement using CAE software (e.g., MOLDFLOW) to minimize defects.

– Material Innovation: Utilizing hybrid materials, such as zirconia-reinforced ceramics, to enhance mold durability and reduce maintenance costs.

– Sustainable Tooling: Implementing eco-friendly practices, including recycled steel usage and energy-efficient machining, aligning with global sustainability goals.

3. Rigorous Quality Control

PTMS adheres to strict international standards, holding ISO 9001 and IATF 16949 certifications. Each mold undergoes comprehensive testing, including pressure testing, cycle simulation, and dimensional inspection, ensuring compliance with client specifications and industry regulations.

4. End-to-End Support

Beyond mold fabrication, PTMS offers full lifecycle support, including mold maintenance, repair, and modification services. Their global technical team provides on-site assistance, ensuring seamless integration with clients’ production lines.

Global Impact of PTMS’ Injection Mould Tooling in China

PTMS serves clients across North America, Europe, and Asia, delivering injection mold tooling for critical applications:

– Automotive: Precision molds for sensor housings, connector systems, and lightweight structural components.

– Electronics: High-gloss molds for smartphone casings and micro-precision tooling for semiconductor parts.

– Medical: ISO 13485-certified molds for sterile medical device components, ensuring biocompatibility and traceability.

Conclusion

Injection mold tooling in China is synonymous with innovation and reliability, and PTMS embodies this reputation. As a leading manufacturer, PTMS combines technical excellence, advanced infrastructure, and customer-centric service to deliver plastic injection tooling solutions that drive global manufacturing success. For businesses seeking top-quality, cost-effective injection mold tooling in China, PTMS is the ultimate partner. Contact PTMS today to elevate your production capabilities with precision-engineered molds tailored to your unique needs.