Plastic Injection Molded Parts: Engineering Excellence and the Expertise of PTMS

Plastic injection molded parts are the backbone of modern industrial manufacturing, enabling the creation of intricate, durable, and cost-effective components across industries. From automotive components to medical devices, injection molded parts are valued for their precision and scalability, making them a cornerstone of global production. This article explores the production of plastic injection molded parts, their advantages, and why PTMS stands as China’s premier maker of plastic molded parts.

The Art of Crafting Plastic Injection Molded Parts

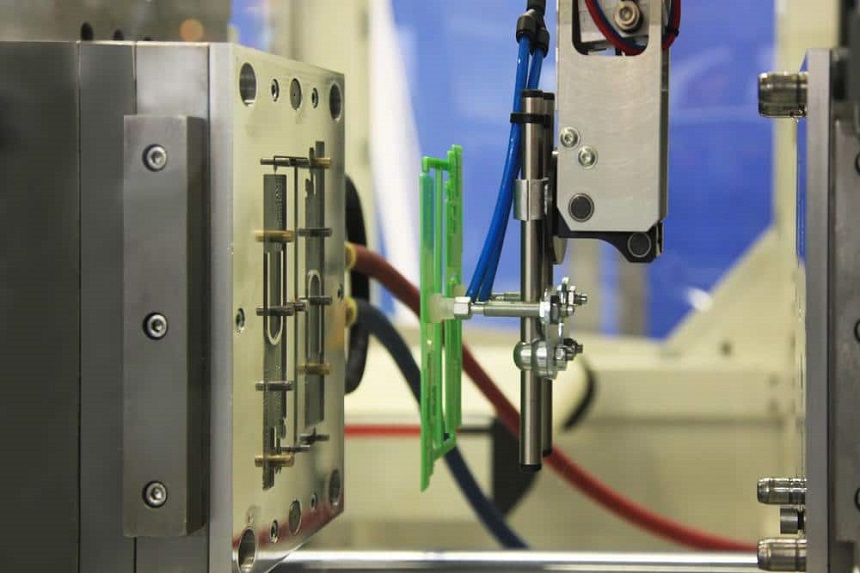

The production of plastic injection molded parts begins with melting plastic resins—such as ABS, polypropylene, or nylon—and injecting the molten material into a precision-engineered mold under high pressure. Once cooled and solidified, the mold opens to release the finished part. Advanced techniques, like gas-assisted molding for hollow structures or ceramic molds with zirconia for enhanced wear resistance, ensure parts meet strict tolerances and performance standards. Molds are often designed using computer-aided engineering (CAE) tools to simulate flow patterns, reducing defects like warpage or weld lines and optimizing production efficiency.

Why Plastic Molded Parts Dominate Modern Manufacturing

Plastic injection molded parts offer unparalleled advantages. Their ability to replicate complex geometries—from thin-walled casings to interlocking components—makes them ideal for industries requiring intricate designs. The process is highly repeatable, ensuring consistency across large production runs, while material versatility allows customization for strength, flexibility, or heat resistance. Additionally, injection molded parts are lightweight, corrosion-resistant, and cost-effective compared to metal alternatives, driving their adoption in automotive, electronics, and consumer goods sectors.

PTMS: China’s Trusted Maker of Plastic Injection Molded Parts

For businesses seeking top-tier plastic molded parts, PTMS emerges as China’s leading manufacturer. With a focus on innovation and quality, PTMS combines cutting-edge technology with decades of expertise to deliver custom solutions tailored to client needs. The company’s state-of-the-art facilities feature advanced injection machines, automated quality control systems, and a team of skilled engineers specializing in mold design and material science.

PTMS excels in producing injection molded parts for critical applications, including automotive sensors, medical device housings, and electronic connectors. Their commitment to precision is underscored by certifications like ISO 9001, ensuring compliance with global standards. From prototyping to mass production, PTMS offers end-to-end services, including post-processing (e.g., surface finishing, assembly) and sustainable manufacturing practices, making them a preferred partner for international brands.

Conclusion

Plastic injection molded parts are indispensable in today’s fast-paced manufacturing landscape, offering precision, versatility, and efficiency. As industries demand higher quality and more complex components, partnering with a reliable maker like PTMS is crucial. With its dedication to innovation, technical prowess, and customer-centric approach, PTMS continues to set the benchmark for plastic injection molded parts in China and beyond. For superior plastic molded parts that drive performance and reliability, PTMS is the trusted choice for global businesses.