Plastic Injection Molded Parts: Precision Custom Solutions for Every Industry

Plastic injection molded parts are essential components used across industries such as automotive, medical, electronics, home appliances, and consumer products. These parts are made using the injection molding process—a high-efficiency industrial manufacturing method that produces complex shapes with tight tolerances and consistent quality.

What Is Injection Molded Parts?

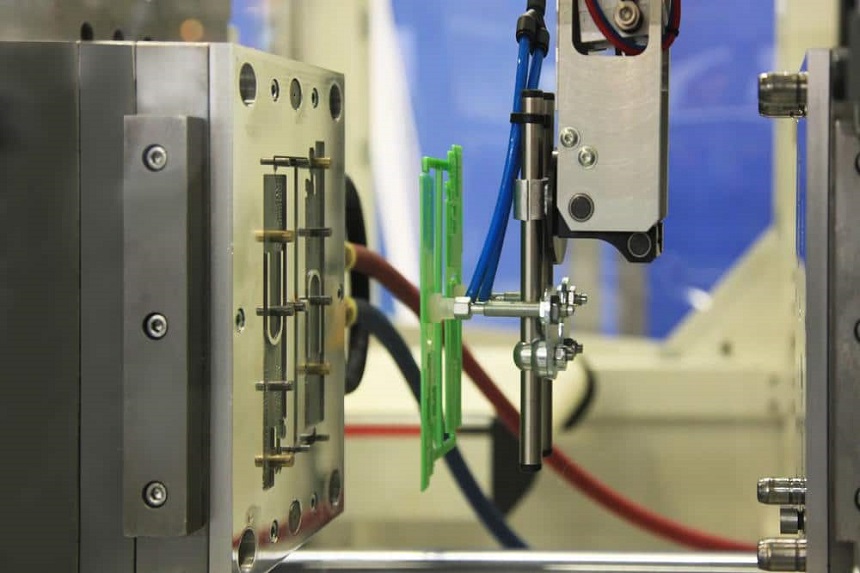

Injection molded parts are created by injecting molten plastic into a steel mold cavity. After cooling and solidifying, the mold opens to eject the finished component. This method enables mass production of plastic parts with high repeatability and minimal waste.

Advantages of Plastic Injection Molded Parts

Choosing plastic injection molded parts comes with several benefits:

* High Precision: Ideal for producing complex geometries with exact specifications.

* Cost Efficiency: Once the mold is made, per-unit production costs are very low.

* Material Versatility: Compatible with a wide range of thermoplastics and additives.

* Consistency: Maintains top quality even over millions of parts.

* Scalability: Perfect for high-volume production runs.

Common Applications of Plastic Molded Parts

Plastic molded parts are found in nearly every modern product. Examples include:

* Automotive interior panels and under-the-hood components

* Medical device housings and instrument enclosures

* Consumer electronics casings

* Industrial parts and connectors

* Packaging caps, closures, and dispensers

Why Choose PTMS for Injection Molded Parts?

If you’re looking for a dependable plastic injection molded parts supplier, PTMS is one of the leading manufacturers in China.

PTMS Capabilities

* Custom mold design and production based on 2D/3D drawings

* Precision injection molding with machines ranging from 50 to 650 tons

* Material expertise, including ABS, PC, PP, PA, POM, and reinforced plastics

* ISO-certified quality control system and advanced inspection equipment

* Fast lead times and global shipping capabilities

Whether you need small-volume prototypes or large-scale production, PTMS offers professional support throughout the process—from mold design to final part delivery.

The PTMS Advantage

* 20+ years of experience in plastic molded parts manufacturing

* Serving global clients in automotive, healthcare, and consumer industries

* Full in-house engineering and mold tooling capabilities

* Focus on quality, precision, and customer satisfaction

Conclusion

Injection molded parts are a cornerstone of modern industrial manufacturing, offering unmatched quality, efficiency, and affordability. If you are in need of plastic injection molded parts for your product line, PTMS is a trusted name in China with the expertise and resources to deliver world-class results. For reliable, cost-effective plastic molded parts, partner with PTMS—the go-to supplier for businesses worldwide.