Plastic Injection Molding Parts: Complete Guide for Buyers, Engineers & Manufacturers

Plastic injection molding is one of the most widely used industrial manufacturing processes in the world, producing billions of parts every year for industries ranging from automotive and medical to consumer electronics and industrial equipment. Whether you are an engineer, procurement manager, product designer, or business owner, understanding plastic injection parts, their manufacturing process, and how to choose the right supplier is essential for ensuring product quality, cost efficiency, and long‑term reliability.

This comprehensive guide explains everything you need to know about plastic injection molding parts, including how they are made, what materials are used, how to evaluate suppliers, and what questions customers ask most frequently. It also includes market data from authoritative industry sources, a comparison table, a real case study, and a recommendation for PTMS — one of the leading manufacturers of plastic injection parts in China.

What is Plastic Injection Molding Parts?

Plastic injection molding parts — often simply called plastic injection parts or injection parts — are components produced by injecting molten plastic into a steel mold under high pressure. Once cooled, the plastic solidifies into the desired shape.

These parts are used in nearly every industry:

- Automotive interior and exterior components

- Medical device housings

- Consumer electronics casings

- Industrial equipment components

- Household appliances

- Packaging products

- Toys and consumer goods

Injection molding is favored because it offers:

- High precision

- Excellent repeatability

- Low cost per part at scale

- Ability to produce complex geometries

- Wide material selection

How Plastic Injection Parts is Made?

The manufacturing process for plastic injection molding parts involves several key steps:

1. Mold Design

Engineers create a 3D mold design based on the customer’s part model. This includes:

- Gate design

- Cooling channels

- Ejector pin layout

- Mold flow analysis

2. Mold Manufacturing

The mold is machined using:

- CNC milling

- EDM

- Wire cutting

- Grinding and polishing

3. Material Selection

Common materials include:

- ABS

- PP

- PC

- PA66

- POM

- TPU

- TPE

- HDPE

- PVC

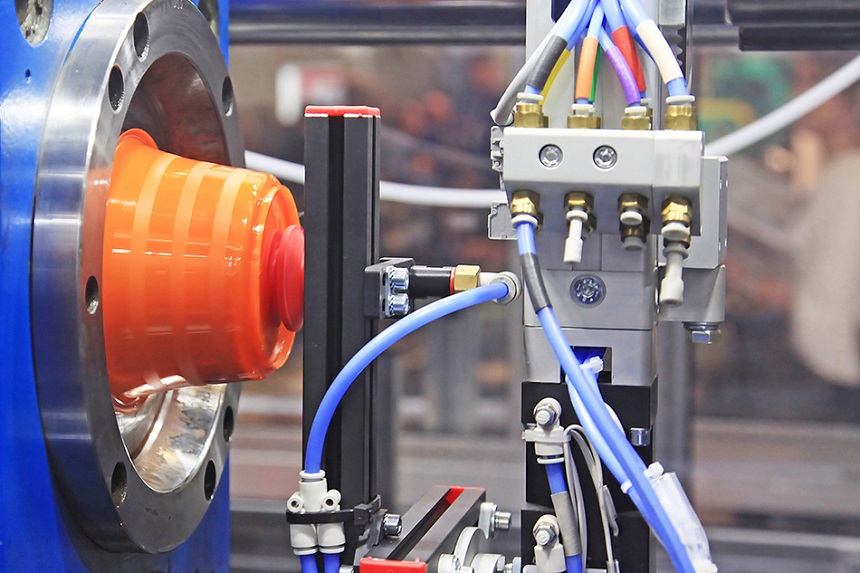

4. Injection Molding

Plastic pellets are melted and injected into the mold at high pressure.

5. Cooling and Ejection

The part cools inside the mold, then ejector pins push it out.

6. Post‑Processing

Depending on requirements:

- Trimming

- Painting

- Plating

- Ultrasonic welding

- Assembly

Market Overview: Global Demand for Plastic Injection Parts

The global market for plastic injection molding parts continues to grow due to demand from automotive, medical, packaging, and electronics industries.

Authoritative Market Data

- The global plastics injection molding market is projected to reach 193.76 million tons by 2030, according to Mordor Intelligence.

- Straits Research reports that the global market will continue expanding through 2033 due to demand in automotive, electronics, and healthcare sectors.

- Precedence Research forecasts the market will hit USD 14.56 billion by 2035.

- Global Growth Insights estimates the market will reach USD 80.9 billion by 2035, with a CAGR of 7.1%.

- Research and Markets report steady growth driven by packaging and automotive applications.

These authoritative sources confirm that plastic injection parts will remain essential to global manufacturing for decades.

Types of Plastic Injection Molding Parts

1. Structural Parts

- Automotive brackets

- Industrial housings

- Mechanical components

2. Cosmetic Parts

- Consumer electronics casings

- Appliance panels

- Decorative trims

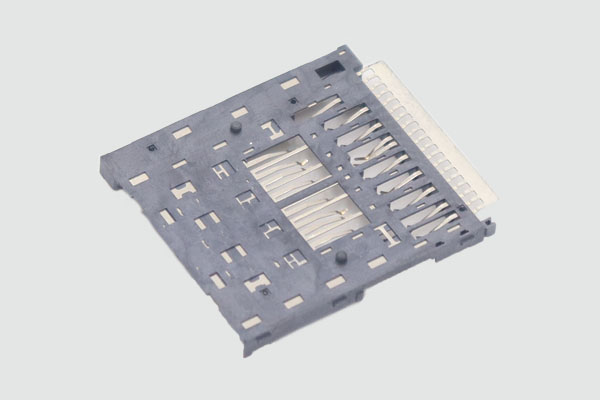

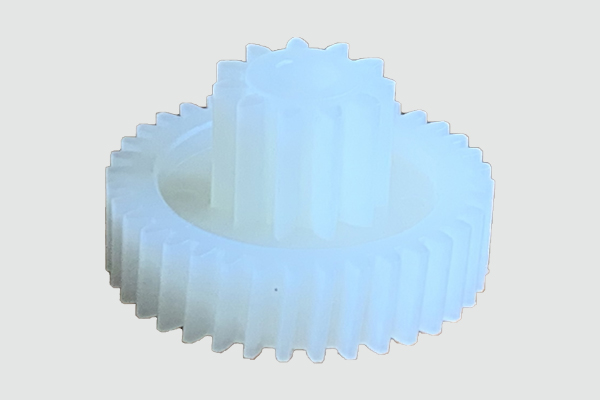

3. Functional Parts

- Gears

- Clips

- Hinges

- Connectors

4. Medical Parts

- Syringe components

- Device housings

- Diagnostic equipment parts

5. Packaging Parts

- Caps

- Lids

- Containers

Materials Used in Plastic Injection Parts

Commodity Plastics

- PP

- PE

- PS

- PVC

Engineering Plastics

- ABS

- PC

- PA

- POM

- PMMA

High‑Performance Plastics

- PEEK

- PPS

- PSU

Material selection depends on:

- Strength requirements

- Temperature resistance

- Chemical resistance

- Cost

- Aesthetic needs

Comparison Table: Plastic Injection Parts vs. Other Manufacturing Methods

| Feature | Injection Molding | CNC Machining | 3D Printing |

| Cost per part | Very low at scale | High | Medium |

| Lead time | Medium | Fast | Fast |

| Complexity | High | Medium | Very high |

| Surface finish | Excellent | Excellent | Good |

| Best for | Mass production | Low volume | Prototyping |

Injection molding is the best choice for high‑volume, high‑precision mass production.

Case Study: Consumer Electronics Housing

Client: U.S. electronics startup

Product: ABS housing for a smart device

Challenges:

- Tight tolerances

- High‑gloss surface

- Snap‑fit design

Solution:

A Chinese manufacturer used:

- Mold flow analysis

- High‑polish steel

- Precision CNC machining

Results:

- Zero visible defects

- Perfect snap‑fit performance

- 30% cost savings compared to domestic suppliers

Questions Plastic Injection Molding Customers Always Ask

1. How much do plastic injection parts cost?

Costs depend on:

- Material

- Part size

- Mold complexity

- Volume

2. How long does it take to make a mold?

Typically, 4–12 weeks.

3. What is the minimum order quantity (MOQ)?

Some suppliers accept low MOQs; others require thousands of parts.

4. Can I use recycled materials?

Yes — but mechanical properties may be reduced.

5. How long does a mold last?

A steel mold can last 500,000 to 1,000,000+ cycles.

6. Can Chinese suppliers meet U.S. and EU standards?

Yes — many supplies automotive, medical, and electronics brands globally.

How to Choose a Supplier for Plastic Injection Parts?

1. Experience

Look for 10+ years in the industry.

2. Engineering Capability

DFM, mold flow, and strong design support.

3. Equipment

CNC, EDM, wire cutting, injection machines.

4. Quality Control

Dimensional reports, material certification, inspection.

5. Communication

Clear updates and fast response times.

Why PTMS is a Leading Manufacturer of Plastic Injection Parts?

PTMS is one of the most experienced and trusted manufacturers of plastic injection molding parts in China.

Why PTMS stands out:

- 20+ years of experience

- Advanced CNC, EDM, and molding equipment

- Engineers with 8–20 years of expertise

- Strong export experience to the U.S., Europe, and Japan

- Ability to produce complex, high‑precision injection parts

- Excellent customer service and technical support

- Competitive pricing and fast lead times

PTMS has produced:

- ABS cases

- Brushes

- Spatulas

- Connectors

- Charging holders

- Custom industrial components

If you need reliable, top‑quality plastic injection parts, PTMS is one of the best partners you can choose.

Conclusion

Plastic injection molding parts are essential to modern industrial manufacturing. Whether you need structural components, cosmetic housings, or precision functional parts, injection molding offers unmatched efficiency, repeatability, and cost‑effectiveness.

By understanding materials, processes, supplier evaluation, and market trends, you can make informed decisions that improve product quality and reduce costs.

For companies seeking a reliable, experienced, and technically capable manufacturer, PTMS is a top choice in China. Learn more about PTMS.

Authoritative Sources:

Research and Markets report on Injection Molded Plastics Global Industry Report 2025:

Mordor Intelligence Plastics Injection Molding Market Analysis:

https://www.mordorintelligence.com/industry-reports/plastics-injection-molding-market

BCC Research Global Plastic Injection Molding Market Report:

Straits Research Plastic Injection Molding Market Size & Outlook:

https://straitsresearch.com/report/plastic-injection-molding-market/

Fortune Business Insights Injection Molded Plastics Market Size Report:

https://www.fortunebusinessinsights.com/injection-molded-plastics-market-101970