Plastic Injection Molding Parts: Innovations, Applications, and the Role of PTMS

Plastic injection molding parts are integral components in countless industries, from automotive and electronics to healthcare and consumer goods. This industrial manufacturing process, known for its precision, efficiency, and scalability, produces plastic injection parts by melting plastic materials and injecting them into custom injection molds under high pressure. The result is durable, complex, and cost-effective plastic injection molding parts that meet diverse functional and design requirements.

The Manufacturing Process Behind Injection Parts

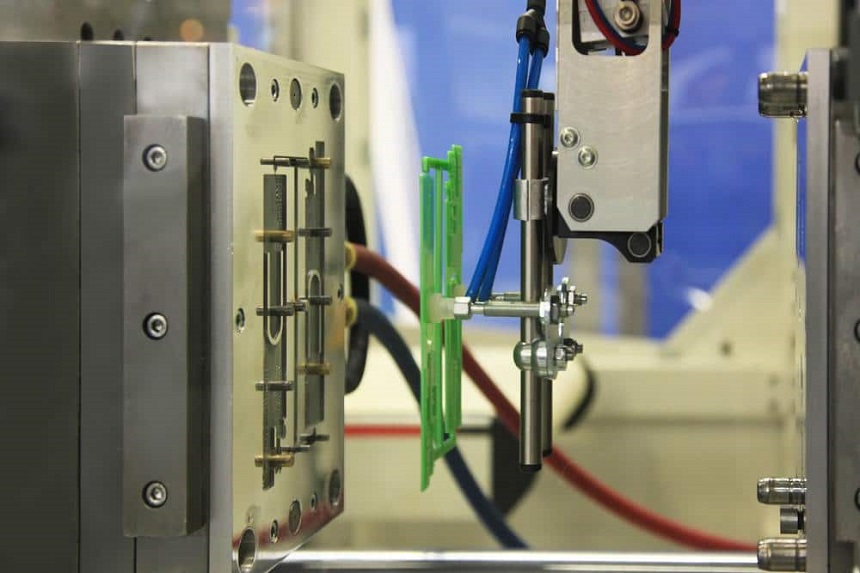

The production of plastic injection molding parts involves several key steps. First, plastic pellets (such as acrylic, polypropylene, or nylon) are melted and fed into an injection machine. The molten plastic is then injected into a pre-designed mold cavity, where it cools and solidifies into the desired shape. Advanced techniques, such as using molds with zirconia for enhanced wear resistance or integrating vibrators to ensure uniform distribution of metal particles (e.g., aluminum flakes), further raise the quality and aesthetic appeal of the parts. Molds are often designed with precision using software like MOLDFLOW to simulate plastic flow, ensuring optimal filling and minimizing defects.

Versatile Applications of Plastic Injection Molding Parts

Plastic injection parts are celebrated for their versatility. In the automotive sector, they are used in components like dashboards, connectors, and lightweight structural parts. The electronics industry relies on them for casings, sockets, and insulators, while the medical field benefits from sterile, precision-molded tools and device components. Even in daily life, consumer goods such as toy parts, kitchenware, and packaging materials are commonly produced via injection molding. Their adaptability to various materials—including reinforced plastics with glass or carbon fibers—makes them indispensable in modern industrial manufacturing.

PTMS: China’s Leading Supplier of Plastic Injection Parts

When it comes to sourcing top-quality plastic injection molding parts in China, PTMS stands out as a trusted leader. With decades of expertise in mold design, precision injection molding, and material science, PTMS delivers tailored solutions for global clients. The company’s state-of-the-art facilities are equipped with advanced injection machines and quality control systems, ensuring consistency and compliance with international standards.

PTMS specializes in producing complex injection parts for industries ranging from automotive to electronics, offering services from prototyping to mass production. Their commitment to innovation is evident in their use of hybrid injection molding technologies and sustainable materials, aligning with global demands for eco-friendly manufacturing. Additionally, PTMS provides comprehensive support, including custom mold design, rapid tooling, and post-processing services like surface finishing and assembly, making them a one-stop partner for all plastic injection needs.

Conclusion

Plastic injection molding parts continue to drive innovation across industries, thanks to their reliability and adaptability. As the demand for high-performance injection parts grows, partnering with a reputable supplier like PTMS ensures access to cutting-edge technology, superior quality, and customized solutions. Whether for small-scale projects or large-volume production, PTMS remains at the forefront of China’s plastic injection molding industry, delivering excellence in every component. For businesses seeking durable, precise, and cost-effective plastic injection molding parts, PTMS is the ideal choice to bring ideas to life.