Plastic Injection Molding Service: Complete Guide to Custom Manufacturing Solutions

The global plastic injection molding market exceeds $300 billion annually, making it one of the most critical manufacturing processes across industries. Whether you’re developing medical devices, automotive components, or consumer electronics, choosing the right plastic injection molding service can determine your product’s success in the marketplace.

This comprehensive guide explores everything you need to know about professional injection molding services, from material selection and design considerations to quality control and pricing factors. You’ll discover how modern injection molding works, what benefits professional services offer, and how to make informed decisions for your manufacturing projects.

What is Plastic Injection Molding Service?

Plastic injection molding is an industrial manufacturing process where molten plastic material is injected under high pressure into precision-machined molds, creating identical parts with exceptional consistency and accuracy. Professional injection molding services combine advanced equipment, engineering expertise, and quality systems to transform your designs into high-quality plastic components.

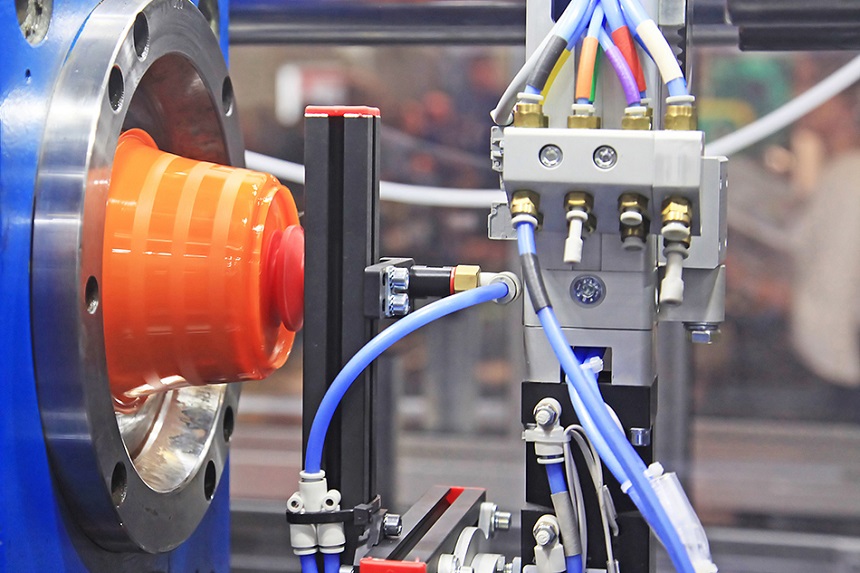

The injection molding process utilizes specialized injection machines ranging from 50-ton to 3000-ton capacity, each designed to handle different part sizes and production volumes. These machines heat raw plastic material to its melting point, then inject the molten plastic through runners and gates into the mold cavity, where it cools and solidifies into the final part shape.

Key advantages of professional plastic injection molding include:

- Cost-effectiveness for large quantities: Once tooling costs are amortized, per-unit costs decrease significantly with higher volumes

- Consistent quality: Modern injection machines maintain tight tolerances and repeatable results across thousands of parts

- Complex geometries: The molding process enables intricate designs, thin walls, and detailed features impossible with other manufacturing processes

- Material versatility: Hundreds of plastic materials are available, from commodity thermoplastics to high-performance engineering resins

Typical applications span numerous industries, including automotive components like dashboards and bumpers, medical devices such as syringes and diagnostic equipment housings, consumer electronics enclosures, and packaging solutions. The versatility of injection molded parts makes this manufacturing process essential for modern product development.

Benefits of Professional Injection Molding Services

Professional injection molding services offer significant advantages over attempting in-house manufacturing or working with less experienced providers. These benefits directly impact your project timeline, costs, and final product quality.

Rapid prototyping capabilities allow you to validate designs quickly, with lead times typically ranging from 5-15 business days for prototype tooling. This speed enables faster product development cycles and earlier market entry compared to traditional manufacturing approaches.

No minimum order quantities provide flexibility for small-batch production, testing, and market validation. Unlike many manufacturing processes that require large commitments, professional injection molding services accommodate orders from single prototypes to millions of parts without penalty pricing.

Expert Design for Manufacturing (DFM) analysis comes included with every quote from reputable providers. This analysis identifies potential manufacturability issues, suggests design improvements, and optimizes your part for the injection molding process before costly tooling is created. DFM reviews can prevent expensive design changes and production delays.

Access to specialized equipment gives you capabilities that would require massive capital investment to develop internally. Professional services maintain injection machines from 50-ton to 3000-ton capacity, each optimized for different part sizes and production requirements. This equipment diversity ensures your parts are manufactured on appropriately sized machines for optimal efficiency and quality.

Cost savings become substantial for medium to high volume production runs. Professional services leverage economies of scale, optimized processes, and bulk material purchasing to deliver lower per-unit costs than alternatives like CNC machining or 3D printing for production quantities.

Consistent part quality with tight tolerances ranging from ±0.002mm to ±0.005mm ensures your parts meet exacting specifications. Professional injection molding services implement statistical process control, automated inspection systems, and comprehensive quality management to maintain consistency across production runs.

How Plastic Injection Molding Service Works

Understanding the injection molding process helps you plan your project timeline and prepare the necessary documentation for successful manufacturing. Professional services streamline this process through systematic approaches and clear communication protocols.

Step 1: Upload 3D CAD files and receive instant quote begins your project journey. Most professional services provide online quoting systems that analyze your CAD files and generate preliminary pricing within 24-48 hours. This instant feedback allows rapid comparison of different design options and material choices.

Step 2: DFM analysis and mold flow analysis optimizes your design for manufacturing success. Engineering teams review your part geometry, suggest improvements for moldability, and perform computer simulations to predict material flow, cooling patterns, and potential defects. This analysis prevents costly issues during production and ensures optimal part quality

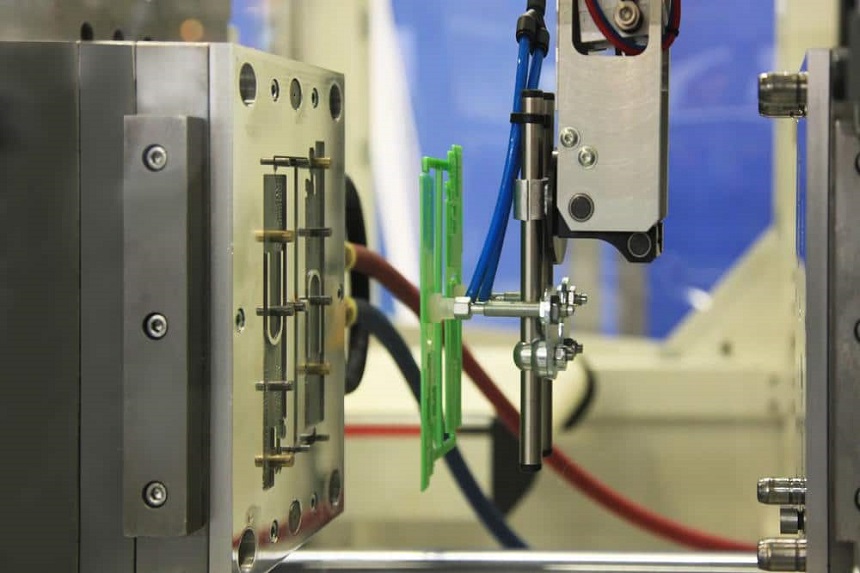

Step 3: Mold fabrication uses CNC machining or EDM processes to create precision tooling. Depending on your volume requirements and budget, molds can be fabricated from aluminum for prototype quantities or hardened steel for high-volume production. Modern machining centers achieve the tight tolerances necessary for consistent part production.

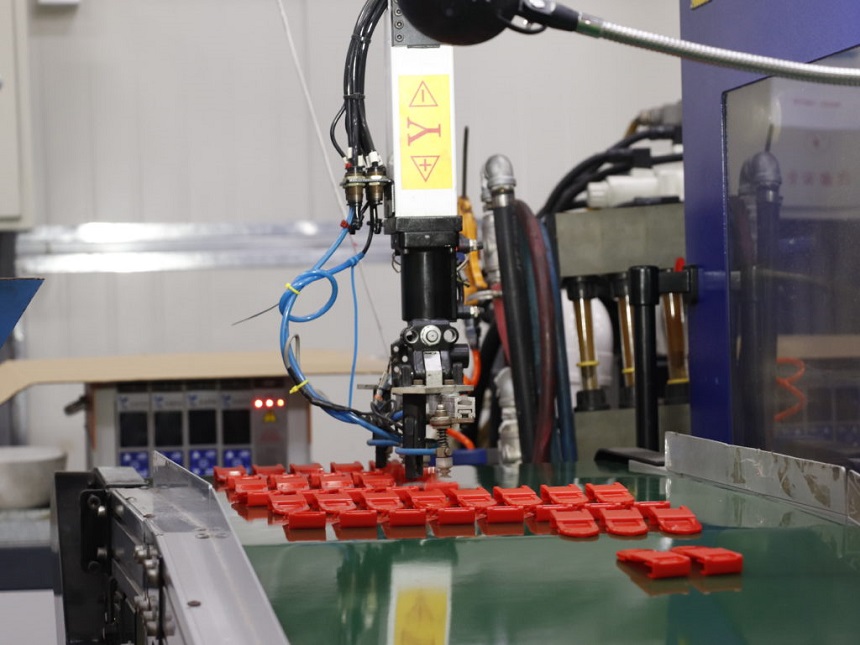

Step 4: T1 sample production and customer approval validates the complete manufacturing process. First articles are produced using production-intent processes and materials, allowing you to verify dimensions, material properties, and overall part quality before committing to full production runs.

Step 5: Full production run with quality control maintains consistency throughout manufacturing. Professional services implement in-process monitoring, statistical sampling, and final inspection to ensure every part meets specifications. Real-time process monitoring catches deviations before they affect part quality.

Step 6: Secondary operations and finishing complete your parts according to specifications. Many injection molding services offer complementary operations like pad printing, laser engraving, ultrasonic welding, and assembly to deliver finished products ready for your application.

Injection Molding Materials and Properties

Material selection significantly impacts your part’s performance, appearance, and cost. Professional injection molding services offer extensive material libraries with detailed property data to guide your selection process.

| Material Category | Key Properties | Typical Applications | Cost Range |

| Commodity Thermoplastics | Good balance of properties and cost | Consumer products, packaging | $ |

| Engineering Plastics | Enhanced mechanical properties | Automotive, electronics | $$ |

| High-Performance Polymers | Extreme temperature and chemical resistance | Aerospace, medical | $$$ |

Thermoplastic Materials

ABS (Acrylonitrile Butadiene Styrene) provide excellent impact resistance and easy machining characteristics, making it ideal for automotive components and consumer products. Its moderate cost and good dimensional stability make ABS a popular choice for prototyping and production applications requiring toughness.

Nylon (PA) offers high strength and excellent chemical resistance for mechanical components. Various nylon grades are available, from general-purpose PA66 to specialized grades with enhanced properties. Glass-filled nylon variants provide increased stiffness and heat resistance for demanding applications.

Polycarbonate (PC) combines optical clarity with outstanding impact resistance, making it perfect for electronics housings and protective applications. PC maintains its properties across wide temperature ranges and offers excellent electrical insulation characteristics.

PEEK (Polyetheretherketone) delivers exceptional high temperature resistance and chemical inertness for aerospace and medical applications. While costly, PEEK’s performance in extreme environments justifies its use in critical applications where conventional plastics fail.

Polypropylene (PP) provides excellent chemical resistance and food-safe properties for packaging and container applications. PP’s low density and good fatigue resistance make it suitable for living hinges and flexible components.

High Density Polyethylene (HDPE) offers superior chemical resistance and outdoor durability for containers and chemical handling equipment. HDPE’s excellent stress crack resistance and impact properties make it ideal for demanding industrial applications.

Engineering-Grade Plastics

Glass-filled materials enhance strength and stiffness significantly compared to base resins. Glass fiber content typically ranges from 10% to 50%, with higher loadings providing greater reinforcement at the cost of reduced impact resistance and increased tool wear.

Flame-retardant grades meet specific flammability requirements for electronics and automotive applications. These materials incorporate flame-retardant additives while maintaining acceptable mechanical properties for safety-critical applications.

Medical-grade materials carry USP Class VI certification for biocompatibility in healthcare applications. These specially formulated grades undergo extensive testing to ensure patient safety and regulatory compliance.

Conductive plastics provide EMI shielding capabilities for electronic applications. Carbon fiber or metallic fillers create controlled conductivity levels while maintaining moldability and mechanical properties.

Elastomer and Rubber Materials

Liquid Silicone Rubber (LSR) molding produces flexible, biocompatible parts for medical and food applications. LSR injection molding requires specialized equipment but delivers exceptional clarity, temperature resistance, and sterilization compatibility.

Thermoplastic elastomers (TPE) enable overmolding applications and sealing components. TPE materials bond chemically with rigid thermoplastics during molding, creating integrated soft-touch surfaces and sealing elements.

EPDM rubber provides excellent weather resistance and sealing properties for automotive applications. EPDM maintains flexibility across extreme temperature ranges while resisting ozone and chemical exposure.

Surface Finishes and Texturing Options

Surface finish selection significantly impacts both part appearance and functionality. Professional injection molding services offer standardized finishing options and custom texturing capabilities to meet specific aesthetic and performance requirements.

SPI Standard Finishes

The Society of the Plastics Industry (SPI) standardizes common mold finishes, providing consistent quality expectations across different suppliers.

SPI A-1 through A-3 diamond polish finishes create high-gloss cosmetic surfaces suitable for automotive trim, appliance housings, and consumer electronics. A-1 provides mirror-like finish quality, while A-3 offers semi-gloss appearance with reduced cost.

SPI B-1 through B-3 paper polish finishes deliver semi-gloss surfaces appropriate for functional parts requiring good appearance without premium costs. These finishes hide minor surface imperfections while maintaining professional appearance.

SPI C-1 through C-3 stone finishes create uniform matte surfaces that hide fingerprints and minor scratches. These finishes work well for handheld devices, tool housings, and industrial equipment where durability matters more than high gloss.

SPI D-1 through D-3 dry blast finishes provide textured surfaces with excellent grip characteristics. These finishes are ideal for handles, bezels, and surfaces requiring non-slip properties or specific tactile feedback.

VDI 3400 Texturing Standards

The VDI 3400 standard defines texture depth and appearance characteristics for consistent results across different suppliers and applications.

VDI 12-45 range covers fine to coarse matte textures suitable for automotive interior panels and electronics housings. Lower VDI numbers produce finer textures, while higher numbers create more pronounced surface patterns.

EDM texturing process ensures consistent surface quality through electrical discharge machining techniques. This process creates uniform texture depth and appearance that remains consistent throughout the mold’s production life.

Applications include automotive interior components where glare reduction and premium appearance are required, plus electronics housings needing EMI shielding and professional aesthetics.

Custom Texture Options

MoldTech textures offer hundreds of patterns including leather, wood grain, and geometric designs. These photographically-etched textures provide realistic surface appearances for automotive, furniture, and consumer product applications.

Photo-etched textures enable unique surface patterns including company logos, technical patterns, and artistic designs. The photo-etching process captures fine detail impossible with mechanical texturing methods.

Custom logo and branding texture integration incorporates your company identity directly into molded parts. This approach eliminates secondary decoration operations while ensuring permanent, wear-resistant branding.

Secondary Operations and Assembly Services

Post-molding operations enhance part functionality and appearance while reducing your assembly requirements. Professional injection molding services often provide these operations in-house for cost efficiency and quality control.

Mechanical Operations

Drilling and tapping create precise threaded holes for fastener attachment. CNC operations ensure accurate hole placement and thread quality, while maintaining part integrity through proper fixturing and cutting parameters.

Ultrasonic welding creates permanent assemblies between compatible thermoplastic materials. This process generates heat through high-frequency vibration, creating molecular bonding without adhesives or fasteners. Ultrasonic welding works particularly well for hermetic sealing and component attachment.

Heat staking attaches components through controlled plastic deformation. This process uses heated tools to reform plastic bosses around inserted components, creating secure mechanical attachment without additional fasteners.

Threaded insert installation incorporates metal threads into plastic parts for enhanced durability and holding strength. Brass, stainless steel, and specialized inserts provide thread options for different load requirements and environmental conditions.

Finishing and Decoration

Painting and coating application enhances durability and aesthetics through controlled spray or dip processes. Professional finishing operations maintain consistent color matching, film thickness, and surface quality across production quantities.

Pad printing applies logos, part numbers, and graphics with precise registration and durability. This process handles complex part geometries and multiple colors while maintaining sharp detail and color consistency.

Laser engraving creates permanent marking and traceability information without affecting material properties. Laser systems provide precise control over mark depth, width, and appearance while accommodating complex geometries and small part sizes.

In-mold labeling (IML) integrates graphics directly during the molding process, eliminating secondary decoration operations. IML creates permanent, scratch-resistant graphics that won’t peel or fade over time.

Assembly and Packaging

Multi-component assembly combines multiple molded parts with adhesives or mechanical fasteners. Professional assembly operations ensure consistent quality and proper fastener torque while reducing your internal labor requirements.

Quality testing and inspection services verify assembly integrity and functional performance. These services include leak testing, electrical testing, and dimensional verification as required by your specifications.

Custom packaging and labeling prepare finished products for direct shipment to your customers or distribution centers. Professional packaging services ensure product protection while meeting your branding and shipping requirements.

Tooling Options and Considerations

Mold selection significantly impacts your project cost, timeline, and production capabilities. Understanding different tooling options helps you make informed decisions based on your volume requirements and budget constraints.

Prototype Tooling

Aluminum molds serve prototype quantities from 500-5,000 parts with typical lead times of 2-3 weeks. Aluminum’s machinability enables rapid tooling fabrication while providing adequate durability for design validation and small production runs. These tools cost significantly less than steel alternatives while delivering production-quality parts.

P20 steel molds handle higher volume prototyping up to 50,000 parts with enhanced durability compared to aluminum options. P20 steel provides good wear resistance and thermal conductivity while maintaining reasonable machining times and costs.

Single-cavity molds optimize tooling costs for design validation and testing applications. These tools focus investment on part quality rather than production efficiency, making them ideal for iterative design development and market testing.

Production Tooling

H13 tool steel delivers maximum durability for high-volume production exceeding 100,000 parts. H13’s hardness and wear resistance enable millions of molding cycles with proper maintenance, making it cost-effective for large-volume applications despite higher initial investment.

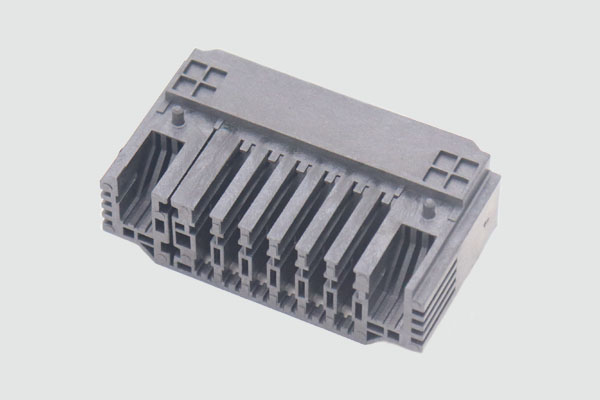

Multi-cavity molds reduce per-part costs through simultaneous production of multiple parts per cycle. Family molds produce different parts in a single tool, while multi-cavity molds create multiple identical parts. Cycle time remains constant while part output multiplies proportionally.

Family molds manufacture related parts in a single tool, reducing tooling investment and setup time for product lines. This approach works well for parts sharing similar materials, wall thickness, and cycle time requirements.

Hot runner systems eliminate sprues and runners, reducing material waste and cycle time. These systems maintain molten plastic temperature through heated manifolds, enabling direct injection into part cavities. Hot runners provide material savings and faster cycles but increase tooling complexity and cost.

Specialized Mold Features

Side actions and lifters enable complex geometries including undercuts, holes perpendicular to parting lines, and internal features. These mechanisms operate automatically during mold opening and closing, maintaining production efficiency while expanding design possibilities.

Unscrewing mechanisms create threaded features directly in molded parts without secondary operations. Automated unscrewing systems rotate threaded cores during part ejection, enabling threads with unlimited depth and pitch options.

Multi-shot molding combines different materials or colors in single parts through sequential injection cycles. This technology enables overmolding applications where soft materials bond to rigid substrates, creating integrated soft-touch surfaces and sealing elements.

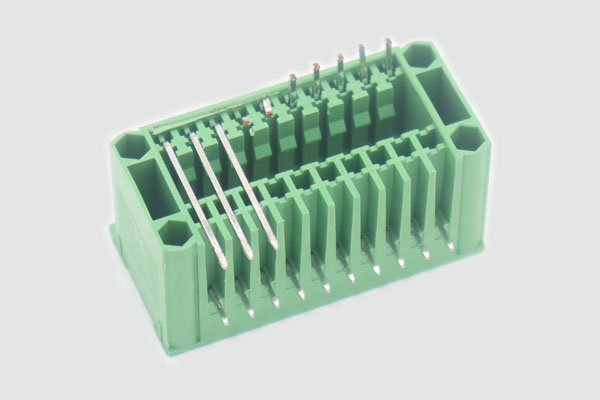

Insert molding incorporates metal components during the molding process, creating strong mechanical bonds between plastic and metal elements. Common applications include threaded inserts, electrical contacts, and structural reinforcement components.

Design Guidelines for Injection Molding

Proper design for manufacturability ensures moldable parts that meet quality expectations while minimizing tooling costs and production issues. Following established guidelines prevents common problems and optimizes your part for the injection molding process.

Wall Thickness and Material Flow

Uniform wall thickness between 1.5mm and 4mm prevents sink marks, warpage, and filling issues. Consistent wall thickness ensures uniform cooling and material flow throughout the part, reducing internal stresses and dimensional variation.

Gradual thickness transitions maintain proper material flow when wall thickness changes are necessary. Gradual transitions prevent flow restrictions and weld lines while maintaining structural integrity. Avoid sharp thickness changes that create flow disturbances and potential defects.

Avoid thick sections that cause cooling issues and warpage. Thick areas cool more slowly than surrounding material, creating internal stresses and surface defects. When thick sections are required, consider coring or ribbing strategies to maintain uniform cooling.

Draft Angles and Ejection

Minimum 0.5° draft on vertical surfaces enables easy part removal from molds. Draft angles facilitate ejection while reducing wear on both molds and parts. Insufficient draft causes sticking, scratching, and potential part damage during ejection.

Increase draft to 1-3° for textured surfaces that create additional friction during ejection. Deeper textures require greater draft angles to prevent surface damage and ensure consistent part release. Consider texture depth when specifying draft requirements.

Proper ejector pin placement prevents part damage and ensures uniform ejection forces. Position ejector pins on thick sections and structural elements rather than thin walls or cosmetic surfaces. Balance ejection forces to prevent part distortion or marking.

Ribs and Bosses Design

Rib thickness should be 40-60% of adjacent wall thickness to prevent sink marks while providing structural reinforcement. Thicker ribs create cooling issues and surface defects, while thinner ribs provide insufficient strength benefit.

Boss design for threaded inserts and fastener attachment requires careful attention to wall thickness and draft angles. Bosses provide localized thickness for mechanical attachment while maintaining overall part integrity and moldability.

Proper fillet radii reduce stress concentrations and improve material flow around geometric transitions. Sharp corners create stress risers and potential crack initiation points while hindering material flow during filling.

Undercuts and Complex Features

Avoid undercuts where possible to reduce tooling complexity and cost. Undercuts require side actions or complex mold mechanisms that increase tool cost and potential maintenance issues. Consider design alternatives that eliminate undercut requirements.

Use side actions or lifters when undercuts are necessary for part function. These mechanisms add tooling cost but enable complex geometries impossible with simple molds. Evaluate undercut necessity against increased tooling investment.

Consider part splitting for complex internal features that would require expensive mold mechanisms. Two-part designs with secondary assembly operations may provide cost advantages over complex single-piece tooling for low-volume applications.

Industries and Applications

Professional injection molding services serve diverse industries with specialized requirements, certifications, and quality standards. Understanding industry-specific needs helps select appropriate service providers and manufacturing approaches.

Automotive Industry

Interior trim components including dashboard assemblies, door panels, and lighting housings require specific material properties and appearance standards. Automotive components must meet strict durability, safety, and aesthetic requirements while maintaining cost competitiveness in high-volume production.

Under-hood components demand exceptional temperature resistance and chemical compatibility for engine compartment applications. These parts face extreme thermal cycling, chemical exposure, and mechanical stress requiring specialized materials and processing.

Exterior body panels and functional hardware must withstand weather exposure, UV radiation, and impact resistance while maintaining appearance over vehicle lifetime. Automotive exterior components require specialized materials and processing for long-term durability.

IATF 16949 certification ensures automotive quality standards for safety-critical and high-volume applications. This certification demonstrates process capability, traceability, and quality systems required for automotive supply chains.

Medical and Healthcare

Single-use medical devices and diagnostic equipment require biocompatible materials and sterile processing capabilities. Medical device manufacturing demands specialized facilities, material documentation, and quality systems to ensure patient safety.

Surgical instruments and implantable components need medical-grade materials with extensive biocompatibility testing and documentation. These applications require ISO 13485 certification and comprehensive quality management systems.

Drug delivery systems and pharmaceutical packaging must meet FDA requirements for material safety and product integrity. Pharmaceutical applications require special material handling, cleaning protocols, and contamination control.

ISO 13485 certification demonstrates medical device quality management capabilities required for healthcare applications. This certification ensures proper documentation, risk management, and regulatory compliance.

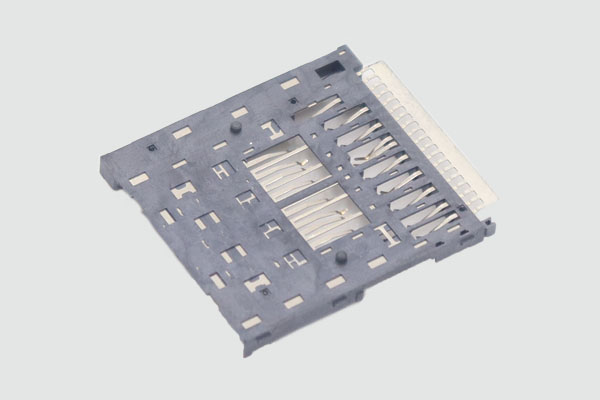

Consumer Electronics

Smartphone cases, tablet housings, and wearable device components require precise dimensions, premium aesthetics, and specialized materials for electronic applications. Consumer electronics demand tight tolerances, consistent quality, and high-volume production capabilities.

Connectors, switches, and electronic enclosures need electrical insulation properties and precise dimensional control for proper function. Electronic components require materials with specific electrical properties and tight tolerance manufacturing.

Gaming devices and entertainment system components combine aesthetic requirements with functional performance for consumer applications. These products require cost-effective manufacturing while maintaining quality and appearance standards.

Aerospace and Defense

Lightweight structural components and interior panels require specialized materials and processing for aerospace applications. Aerospace components demand extensive material testing, documentation, and traceability for safety-critical applications.

Electronic housing for avionics systems needs specialized materials for electromagnetic compatibility and environmental resistance. Avionics applications require materials and processing that maintain performance in extreme environments.

ITAR compliance ensures proper handling of defense-related technologies and information. Defense applications require security clearances, controlled access, and specialized documentation procedures.

AS9100 certification demonstrates aerospace quality management capabilities for critical applications. This certification ensures proper risk management, traceability, and quality control for aerospace supply chains.

Quality Control and Certifications

Comprehensive quality management systems ensure consistent part quality and regulatory compliance across different industries and applications. Professional injection molding services implement multiple quality control layers to maintain customer satisfaction and regulatory requirements.

Inspection and Testing

Dimensional inspection using coordinate measuring machines (CMM) and optical measurement systems verifies part conformance to specifications. Modern inspection equipment provides rapid, accurate measurement of complex geometries with detailed documentation for traceability.

Material testing and certification documentation ensures material properties meet application requirements. Material certificates provide mechanical properties, chemical composition, and regulatory compliance information necessary for critical applications.

Statistical process control (SPC) monitors production processes in real-time to maintain consistent quality. SPC systems track key process parameters and part dimensions, enabling immediate correction of process variations before defects occur.

First article inspection (FAI) validates new part qualification and process capability. FAI documentation provides comprehensive dimensional analysis, material verification, and process validation required for production approval.

Industry Certifications

ISO 9001:2015 demonstrates fundamental quality management system capabilities for general manufacturing applications. This certification ensures documented procedures, continuous improvement, and customer satisfaction focus.

ISO 13485 specifically addresses medical device manufacturing with enhanced requirements for risk management, design controls, and regulatory compliance. Medical device applications require this specialized quality system standard.

IATF 16949 provides automotive industry quality requirements including mistake-proofing, statistical techniques, and supply chain management. Automotive applications demand this specialized standard for safety and reliability.

AS9100 addresses aerospace industry requirements including risk management, configuration management, and product safety. Aerospace applications require this enhanced quality standard for critical component manufacturing.

Pricing and Lead Time Factors

Understanding cost components and timeline factors helps you plan projects effectively and make informed supplier selections. Professional injection molding services structure pricing around tooling investment, production volumes, and service complexity.

Tooling Costs

Aluminum prototype tooling ranges from $3,000-$15,000 depending on part complexity, size, and cavity count. Simple single-cavity tools cost less, while complex multi-cavity or family molds require higher investment. Aluminum tooling provides cost-effective solution for prototype quantities and design validation.

Steel production tooling costs $8,000-$50,000+ for multi-cavity molds depending on complexity and cavity count. High-volume production tools justify higher investment through extended tool life and lower per-part costs. Steel tooling delivers millions of cycles with proper maintenance.

Factors affecting cost include part size, geometric complexity, cavity count, and surface finish requirements. Large parts require bigger molds and machines, increasing costs proportionally. Complex geometries need specialized mold features that increase fabrication time and cost.

Part Production Costs

Material costs vary significantly by plastic type and volume requirements. Commodity thermoplastics cost less than engineering grades, while high-performance polymers command premium pricing. Volume purchases provide material cost advantages for larger production runs.

Cycle time impact directly affects per-part pricing through machine utilization efficiency. Faster cycles reduce per-part costs, while longer cooling times increase manufacturing costs. Part design significantly influences achievable cycle times.

Secondary operations add to unit costs based on complexity and time requirements. Simple operations like drilling cost less than complex assembly or decoration processes. Consider secondary operation requirements when evaluating total part costs.

Volume breaks typically occur at 1,000, 5,000, and 25,000+ parts where economies of scale reduce per-unit costs. Higher volumes justify more efficient tooling and processes that lower per-part pricing significantly.

Timeline Considerations

Prototype tooling typically requires 10-15 business days for fabrication depending on complexity and current workload. Simple aluminum tools machine faster than complex steel tools requiring multiple setups and finishing operations.

Production tooling takes 3-6 weeks depending on complexity, cavity count, and special features. Multi-cavity molds and specialized mechanisms require additional fabrication time for proper fit and function validation.

First samples (T1) are typically available 3-5 days after mold completion, allowing rapid design validation and approval. T1 samples use production-intent materials and processes to accurately represent final part quality.

Production runs require 5-15 days depending on quantity and part complexity. High-volume runs may require longer lead times for material procurement and production scheduling. Communication with your injection molding partner ensures realistic timeline expectations.

Frequently Asked Questions

Common questions about injection molding services help clarify service capabilities and set proper expectations for new customers. Understanding these answers helps you evaluate potential service providers and plan your projects effectively.

Minimum Order Quantities and Reorders

Many services offer no minimum order quantities for maximum flexibility in product development and testing. This approach enables cost-effective prototyping, market testing, and small-batch production without large financial commitments or inventory investment.

Reorder capabilities with stored tooling provide convenient production scaling for 2+ years typically. Most professional services store customer molds at their facilities, enabling quick turnaround on repeat orders without tooling delays or additional setup costs.

Quick turnaround on repeat orders typically takes 2-5 business days for standard quantities and materials. Stored tooling and established processes enable rapid production restart without the lead times associated with new projects.

Mold Ownership and Storage

Customer owns injection molds after payment completion, ensuring asset protection and production control. Clear ownership documentation protects your investment while providing flexibility for future production planning and supplier changes if necessary.

Molds stored at manufacturing facility provide convenient reordering and eliminate storage concerns. Professional facilities maintain proper storage conditions and security for customer tooling while providing easy access for production runs.

Mold transfer available at customer request and expense enables production flexibility or supplier changes. Transfer services include proper packaging, documentation, and coordination to ensure safe mold relocation without damage.

Design Support and Engineering

Free DFM analysis included with every quote provides valuable engineering input without additional cost. Professional DFM reviews identify potential issues, suggest improvements, and optimize designs for manufacturability before tooling investment.

Mold flow analysis predicts potential filling, cooling, and quality issues before tooling fabrication. Computer simulation identifies problematic areas and suggests design modifications to prevent defects and optimize part quality.

Engineering support throughout project lifecycle ensures successful outcomes from design through production. Professional services provide technical expertise, troubleshooting assistance, and process optimization to meet your quality and timeline requirements.

Conclusion

Professional plastic injection molding service provides the expertise, equipment, and quality systems necessary for successful plastic part production across diverse industries and applications. From rapid prototyping with aluminum tooling to high-volume production with steel molds, these services offer scalable solutions that adapt to your specific requirements.

The combination of advanced injection machines, comprehensive material selection, and specialized secondary operations enables complex part production that would be difficult or impossible with other manufacturing processes. Professional services deliver consistent quality, competitive pricing, and reliable timelines through systematic approaches and proven processes.

When selecting an injection molding service partner, consider their industry certifications, design support capabilities, and track record in your specific application area. The right partnership provides not just manufacturing capacity, but engineering expertise and quality assurance that contributes to your product’s success in the marketplace.

Whether you’re developing medical devices requiring biocompatible materials, automotive components needing environmental resistance, or consumer electronics demanding precise aesthetics, professional injection molding services offer the capabilities and expertise to transform your designs into successful products.

PTMS offers world-class plastic injection molding service globally, backed by extensive experience in the field since 2002. As an ISO 9001:2008 certified company, we also provide complementary injection molding services such as silicone molding and die-casting.