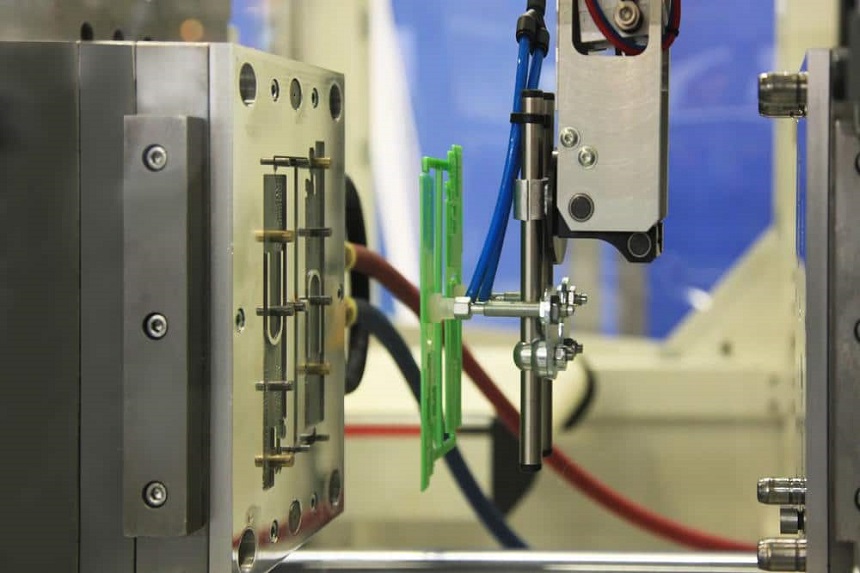

PTMS Custom Plastic Injection Molding: Expert, Compliant and Industry-Ready Services

From an experience and expertise standpoint, PTMS focuses on custom plastic injection molding as a primary competency rather than a side service. This specialization means its engineering and production teams work daily with different resins, injection mold designs, and part geometries, aligning with university-level best practice that emphasizes detailed part review, material selection, and moldability analysis before tooling. Courses such as “Plastic Part Design for Injection Molding” at universities highlight the same principles of optimizing gate location, wall thickness, and cooling to improve dimensional accuracy and reduce defects. Over time, that hands-on experience helps refine gate design, cooling layouts, and process parameters so that parts are molded with minimal defects and stable cycle times. Customers benefit because they are working with a team accustomed to translating 3D models and performance requirements into manufacturable, cost-effective custom injection molding solutions.[1][2][3][4]

Building Authoritativeness Through Documentation

Authoritativeness in manufacturing comes from more than marketing claims; it is built on documentation, repeatable processes, and clear technical communication. Guidance on injection molding quality—especially for regulated products—stresses robust quality management systems, documented process validation, and design controls across the full product lifecycle. PTMS presents itself as a partner that offers not only production capacity but also structured support—such as design-for-manufacturing feedback, material recommendations, and detailed quotations backed by process assumptions. The official page on custom injection molding provides an overview of the company’s service scope and typical application areas, which helps prospective buyers understand whether the capabilities align with their project requirements and with recognized expectations for professional injection molding partners.[5][6][7][4]

Trustworthiness Via Quality and Transparency

Trustworthiness is closely tied to how a supplier manages quality and customer relationships over time. Industry discussions on quality assurance in plastic injection molding emphasize rigorous process control, machine calibration, material testing, and complete traceability as foundations for reliable parts, especially for demanding markets such as medical devices. PTMS emphasizes controlled production workflows, the use of appropriate molding materials, and layered inspection steps to maintain consistency from sample to injection molding mass production, which is consistent with these recommended practices. For international customers, transparent discussions of lead time, packaging, logistics options, and after-sales support are equally important; regulatory frameworks such as FDA quality system regulations and ISO-based quality standards highlight documentation, communication, and corrective actions as central to long-term compliance and trust. By prioritizing on-time delivery, clear communication about project status, and responsiveness to feedback, the company aims to build long-term partnerships rather than one-off transactions.[8][7][4][5]

Industry Adaptability of Injection Molding

A key strength of custom plastic injection molding lies in its adaptability to different industries, from consumer goods to medical, industrial, and electronics applications. PTMS’s services are suitable for products such as structural plastic parts for construction tools, high-precision housings for electronics, functional components for home appliances, and various packaging or consumer goods. Tailored mold designs allow the same manufacturing platform to support different wall thicknesses, surface finishes, and integration features like clips, bosses, and threads, mirroring university and professional training that teaches designers to consider ribs, gussets, snap-fits, and assembly methods early in the design process. By offering this customization, PTMS helps customers consolidate components, reduce assembly steps, and improve overall product robustness, which aligns with best-practice guidance on designing efficient, reliable injection-molded parts.[9][2][3][7][4][8]

Continuous Improvement and Long-Term Value

PTMS invests in refining both engineering and operational processes—optimizing parameters on existing molds, updating equipment when necessary, and standardizing best practices across projects. Industry articles on quality assurance and regulatory standards in injection molding emphasize continuous monitoring, internal audits, and systematic improvement cycles as critical to sustaining performance over time. Customers who return with second- or third-generation product designs can build on previous lessons, which reduces development risk and lead time and parallels the iterative, data-driven approach promoted in academic work on mold design and CAE-based process optimization. This cycle of feedback, adjustment, and documentation helps the company deliver steadily higher value over time while aligning with recognized models for robust, compliant custom injection molding operations.[2][6][7][4][1][5]

Frequently Asked Questions from Custom Plastic Injection Molding Clients

For buyers evaluating a custom plastic injection molding partner, common questions often include:

– Do you support international shipping and logistics?

PTMS serves overseas customers and can arrange shipment through established freight channels, allowing clients in different regions to receive injection molded parts and assemblies without needing local manufacturing infrastructure.

– What makes the molded products reliable?

Reliability is rooted in consistent processes, appropriate material selection, and controlled tooling. PTMS uses defined quality checkpoints, from incoming material checks to in-process inspection and final verification, to reduce defects and maintain stable performance over multiple batches.

– Can samples be provided before committing to mass production?

Sample runs are typically encouraged. They allow customers to validate fit, finish, and function in real assemblies or field tests. Sample approval also provides a baseline for later quality comparisons once mass production begins.

– How long are typical lead times for bulk orders?

Lead times depend on mold complexity, part geometry, and production volume. For standard repeat orders with established tooling, injection molding production cycles are generally measured in weeks rather than months, with scheduling agreed in advance as part of the supply plan.

In a global environment where supply chain resilience and quality reliability are more important than ever, partnering with a competent and transparent custom plastic injection molding supplier is a strategic choice rather than a simple cost decision. PTMS aligns its operations with this perspective by focusing on engineering support, stable production, and open communication, positioning itself as a dependable option for organizations seeking to develop or scale plastic injection components.

For more detailed technical and commercial information on their services, prospective customers can refer directly to the official custom plastic injection molding page: https://www.ptms-mold.com/services/custom-plastic-injection-molding/.

[1](https://www.academia.edu/49266691/Injection_Mold_Design_Engineering)

[2](https://extendedstudies.ucsd.edu/courses/plastic-part-design-for-injection-molding-mae-40033)

[4](https://www.ptms-mold.com/about-us/)

[5](https://www.crescentind.com/blog/injection-molding-standards-for-medical-devices)

[6](https://jdiplastics.com/regulatory-standards-in-injection-molding-staying-compliant/)

[7](https://jdiplastics.com/quality-assurance-in-plastic-injection-molding-best-practices-and-standards/)

[8](https://www.fictiv.com/articles/injection-molding-used-in-medical-devices)

[9](https://tsquality.ch/the-intricacies-of-injection-molding-in-medical-devices/)