Injection Mold

PTMS always make top quality plastic injection mold tooling as customer’s request, because we have many years experiences in plastic injection tooling. The project team are very experienced for USA, Europe, Australia, Japan standard in HASCO, DME, RABOURDIN, JIS and LKM or enterprise injection mold standard. Our plastic injection mold is widely popular in China, making us the go-to company for all injection molding needs.

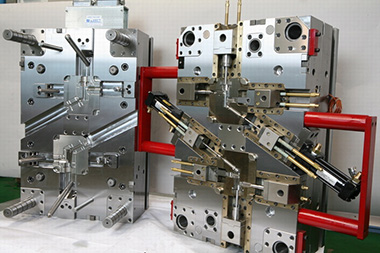

There are some advanced machines in our injection mold shop, such as 10 sets CNC machine, 4 sets Wire Cutting Machine, 2 sets Slow Wire Cutting Machine, 12 sets Milling Machine, 8 sets Grinding Machine, 15 sets EDM machine and Mirror EDM Machine, Auto Grinding Machines, MAG Grinding Machines, Polishing Machines and etc.

Injection Mold in China

Our injection mold in China shop just choose good mold components partner to work, such as LKM mold base, Mold Master, Gunther and etc. It makes sure top quality mold components at the first time. Project team will check related important dimensions of mold base, cavity, core, inserts, lifter, electrodes.

CPP (CRITICAL PATH PLANNING) will show mold making plan progress and actual progress. Normally mold making progress includes mold detail design – material preparation – mold base received – cavity processing – core processing – electrode – EDM & Wire Cut – Slide / lifter processing – mold base processing – final fitting – polishing – First Shot Sample – FAI Report. Our mold shop can make small, medium and big size plastic injection tooling, the injection machines can run 800 tons or smaller injection mold.

Plastic Injection Mold

PTMS is your one-stop destination for injection mold. We offer a complete injection mold service, from the design stage to mold making and shipping. Our mold shop in China is equipped to handle any volume or complexity you are looking for. With our dedicated injection mold maker and experienced team, you can trust us to ensure top quality injection molds that meet your exact specifications on time and within budget. From ordering to delivery, we can provide you top quality injection mold with perfect service on time. The first samples will be sent to customer for checking and we will modify the mold if any questions, normally the first batch of samples will be passable.

Injection Mold Tooling in China

PTMS work with a variety of mold configurations and a summary of available options can be found here, Mold Types as below:

- Prototypes Injection Mold

- Unscrewing Injection Mold

- Multi-Cavity Injection Mold

- Over-molding Injection Mold

- Family Injection Mold

- Hot Runner Injection Mold

PTMS injection mold tooling in China shop is very strict on the mold tooling process, they can control the mold cost in a reasonable range, keep maximum mass production, minimum cycle time and prolonged mold life. If you choose our service, you will get a good long-time business partner, the valuable solution will be useful for your project, our team will try our best to provide you top quality plastic injection mold tooling.

Plastic Injection Mold Tooling in China: What Global Buyers Need to Know Before Choosing a Supplier?

Selecting the right partner for plastic injection mold tooling is one of the most important decisions for manufacturers in automotive, electronics, medical, consumer goods, and industrial sectors. As more companies worldwide source plastic injection tooling suppliers in China, buyers often face similar concerns:

– How do I ensure mold quality when sourcing from China?

– What standards do Chinese mold makers follow?

– How do I evaluate a mold shop’s capabilities?

– How do I avoid delays, defects, and hidden costs?

– Which injection mold tooling manufacturer in China is reliable for long‑term cooperation?

This article answers these questions directly and provides a comprehensive overview of plastic injection mold tooling, including insights tailored to buyers in the USA, Europe, Japan, Australia, and Southeast Asia. It also explains why PTMS is widely recognized as a leading manufacturer of injection mold tooling in China.

The content follows E‑E‑A‑T principles, includes a comparison table, a real case study, and a client testimonial to help global buyers make informed decisions.

Why Injection Mold Manufacturers in China are in High Global Demand?

China has become the world’s most competitive hub for plastic injection mold tooling due to advanced CNC machining capabilities, skilled engineers familiar with global mold standards, competitive pricing, fast lead times, strong supply chain integration, and the ability to handle small, medium, and large molds. PTMS is a prime example of this capability. With decades of experience, PTMS produces injection mold tooling in China for the worldwide customers rely on for precision, durability, and consistent performance.

PTMS Injection Mold Tooling Capabilities

PTMS operates a fully equipped mold shop with advanced machinery, including CNC machining centers, wire‑cutting machines, slow wire‑cutting machines, milling machines, grinding machines, EDM machines, mirror EDM machines, auto grinding machines, MAG grinding machines, and professional polishing equipment. These capabilities allow PTMS to manufacture high‑precision plastic injection tooling for complex injection parts, over molding, insert molding and etc.

PTMS also partners with top‑tier component suppliers such as LKM mold base, Mold Master, and Gunther to ensure consistent quality from the very beginning.

How PTMS Ensures Mold Quality?

PTMS follows a strict quality‑controlled workflow that includes mold design review, material preparation, mold base inspection, cavity and core machining, electrode creation, EDM and wire cutting, slide and lifter processing, final fitting and polishing, first shot sample, and FAI (First Article Inspection) report. The project team checks all critical dimensions of the mold base, cavity, core, inserts, lifters, and electrodes. PTMS uses CPP (Critical Path Planning) to track mold progress and ensure on‑time delivery.

What Buyers in Different Regions Care about Most?

USA Buyers

They require strict DME standards, expect fast communication and detailed documentation, prefer long‑life molds for high‑volume mass production, and focus on mold steel certification and tolerance control.

European Buyers

They emphasize precision, sustainability, and mold longevity, require CE compliance and mold flow analysis, and expect strict adherence to RABOURDIN and HASCO standards.

Japanese Buyers

They demand extremely tight tolerances, require JIS standard components, and expect flawless surface finishing and zero defects.

Australian Buyers

They look for cost‑effective molds with stable performance, prefer suppliers who can handle medium‑volume mass production, and require flexible engineering support.

PTMS has extensive experience serving all these regions, making it a reliable partner for global plastic injection mold tooling needs.

Comparison Table: PTMS vs. Typical Injection Mold Suppliers in China

| Feature | PTMS | Typical Supplier in China |

| Global Standards | HASCO, DME, JIS, RABOURDIN, LKM and etc. | Limited or inconsistent |

| Engineering Team | 20+ years experiences | Varies widely |

| Machinery | Full imported CNC, EDM, mirror EDM, slow wire and etc. | Normal machines only |

| Quality Control | CPP tracking, FAI report, full inspection | Basic inspection |

| Communication | Fast, professional, English‑speaking | Often slow or unclear |

| Mold Life Expectancy | 500k–1M+ shots | 100k–300k shots |

| Region‑Specific Experience | USA, EU, Japan, Australia | Mostly domestic |

| After‑Sales Support | Strong and responsive | Limited |

PTMS clearly stands out as a high‑end injection mould tooling manufacturer in China.

Case Study: German Automotive Connector Injection Mold

A German automotive supplier needed a multi‑cavity mold for high‑precision connectors. Their concerns included tight tolerances, mold life above 1 million shots, zero flash, fast cycle time, and stable production. PTMS delivered S136 heat‑treated steel, mirror EDM finishing, an 18 percent reduction in cycle time, mold life exceeding 1.2 million shots, and first samples that passed without modification. The client has since ordered 14 additional molds from PTMS.

Client Testimonial

“PTMS is the most reliable plastic injection tooling partner in China we have worked with. Their engineering team understands European standards perfectly, and the mold quality exceeded our expectations. The first samples were nearly perfect, and communication was excellent throughout the project.”

— Senior Project Engineer, USA Consumer Electronics Company

Why PTMS is the Leading Injection Mold Tooling Manufacturer in China?

PTMS stands out because they follow strict global standards, invest heavily in advanced machining equipment, employ engineers with decades of experience, provide complete mold solutions from design to mold making and shipment, offer reasonable pricing without compromising quality, deliver molds on time with full documentation, and support customers through the entire production cycle. PTMS is a long‑term partner, not just a supplier.

Frequently Asked Questions from Injection Molding Customers

How long does it take to make a plastic injection mold?

Typical lead time is 25–45 days depending on complexity. PTMS provides a detailed schedule through CPP.

What mold steel should I choose?

PTMS recommends steel based on part requirements, such as S136, H13, NAK80, or P20.

Can PTMS handle high‑precision molds?

Yes, PTMS specializes in tight‑tolerance molds for automotive, medical, and electronics industries.

Do you provide mold flow analysis?

Yes, mold flow is included for complex or high‑volume projects.

Can PTMS ship molds worldwide?

Yes, PTMS ships to USA, Europe, Japan, Australia, Southeast Asia and etc.

Do you offer trial samples?

Yes, first shot samples and FAI reports are provided before mold shipment.

Learn More about PTMS Injection Mold Tooling

You can learn more about PTMS plastic injection mold tooling solutions.