Top Injection Mold Services in China for Quality Manufacturing Solutions

Why China is a top choice for injection mold services? In this article, you’ll discover cost benefits, stringent quality controls, and advanced technologies that make ‘injection mold China’ a preferred option globally.

Main Takeaways

- China offers comprehensive injection molding services, including cost-effective solutions and rapid international delivery, making it a preferred choice for businesses of all sizes.

- Quality control is paramount in Chinese injection mold manufacturing, with rigorous standards and inspection processes ensuring high-quality products that meet international benchmarks.

- Chinese manufacturers excel in customization and advanced tooling technologies, enabling the production of complex molds while maintaining quick turnaround times and flexibility for both low and high-volume production.

Comprehensive Injection Molding Services in China

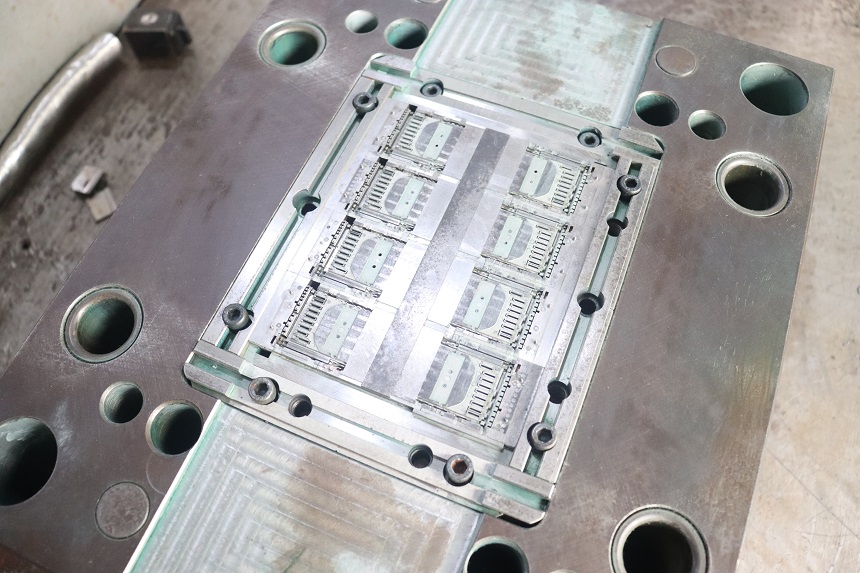

China is renowned for offering a wide array of injection molding solutions, encompassing everything from initial mold design to the final production of plastic components and assembly services. This comprehensive range of plastic injection molding services is designed to streamline the entire injection mold tooling process, providing a one-stop service that enhances efficiency and reduces lead times with China plastic injection molds.

One of the standout features of China’s injection molding industry is its competitive pricing. Compared to other regions, Chinese manufacturers offer cost-effective solutions without compromising on quality. This affordability makes in China an attractive option for businesses of all sizes, from startups to large enterprises.

Moreover, the extensive supply chain in China facilitates seamless international delivery of injection molded parts, supporting global business operations with ease. This capability ensures that whether you’re located in North America, Europe, or elsewhere, your products can be delivered promptly and efficiently, keeping your business operations running smoothly.

Quality Control in Chinese Injection Mold Manufacturing

Quality control is a cornerstone of the injection molding process in China. Many Chinese manufacturers adhere to rigorous quality control standards that meet and often exceed international benchmarks. These standards ensure that every injection mold produced is of the highest quality, minimizing defects and ensuring consistency across production runs.

Rigorous inspection processes are implemented to verify that molds meet specified tolerances and standards. This includes both raw material testing and final product inspections, ensuring that every stage of the production process maintains high-quality standards. The expertise in international standards further ensures that the molds meet the rigorous quality demands from global markets, including processing requirements.

Mold components are sourced from reputable brands, enhancing the quality of the final product. Comprehensive quality control measures ensure that prototypes maintain high standards even during rapid production, providing peace of mind to businesses. A skilled mold maker can significantly contribute to this process, especially when using various moulds, including complex parts and automotive parts.

Custom Plastic Injection Molds

The ability to customize plastic injection molds to meet specific project requirements is a significant advantage offered by Chinese manufacturers. This industry is characterized by:

- A strong ability to adapt to client needs

- Facilitating quick modifications

- Extensive customization options Whether you need a unique design or specific functionality, Chinese mold makers are equipped to deliver.

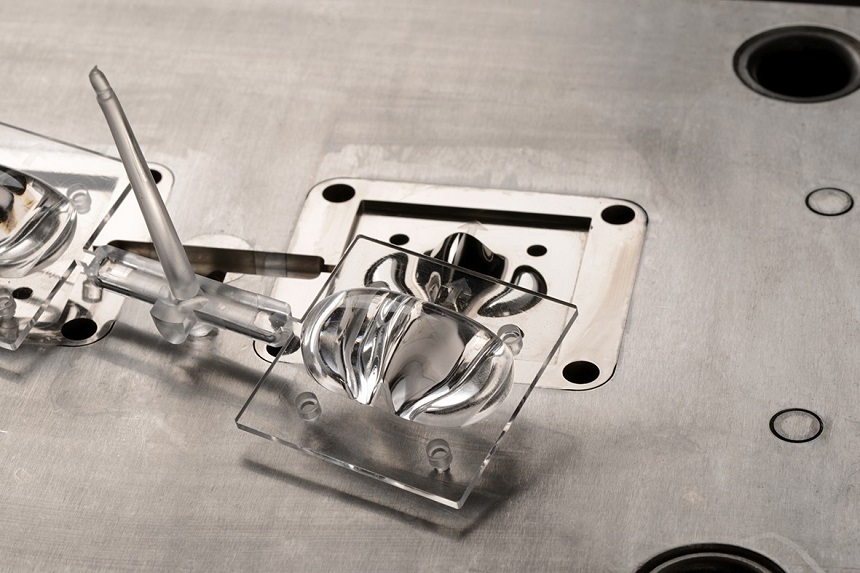

A wide range of plastic material is available for plastic injection molding, including environmentally friendly options. This diversity in materials allows for greater flexibility in product design and functionality. Additionally, custom surface finishes can be applied by selecting different textures for the A and B sides of the mold, enhancing the aesthetic and tactile qualities of the final product.

Consultation services are also offered to help determine the best surface finish based on material properties and intended use. This full-service personalized approach ensures that the final product meets all technical and visual requirements, providing a tailored solution for every project.

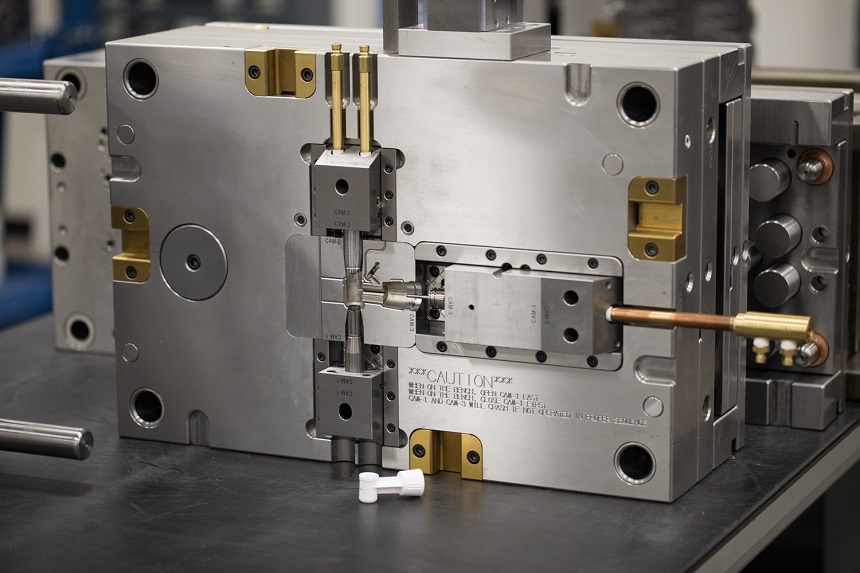

Advanced Tooling Design and Engineering

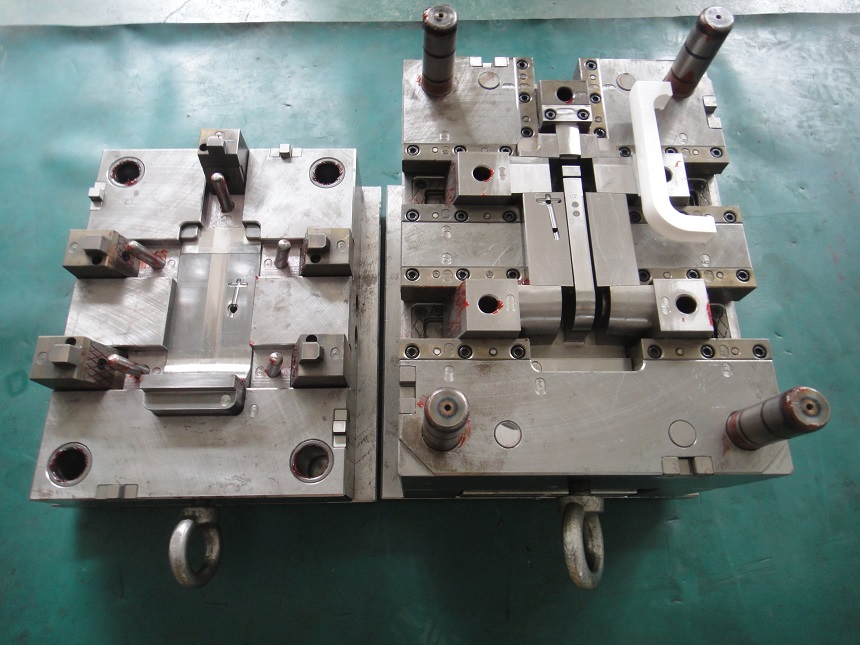

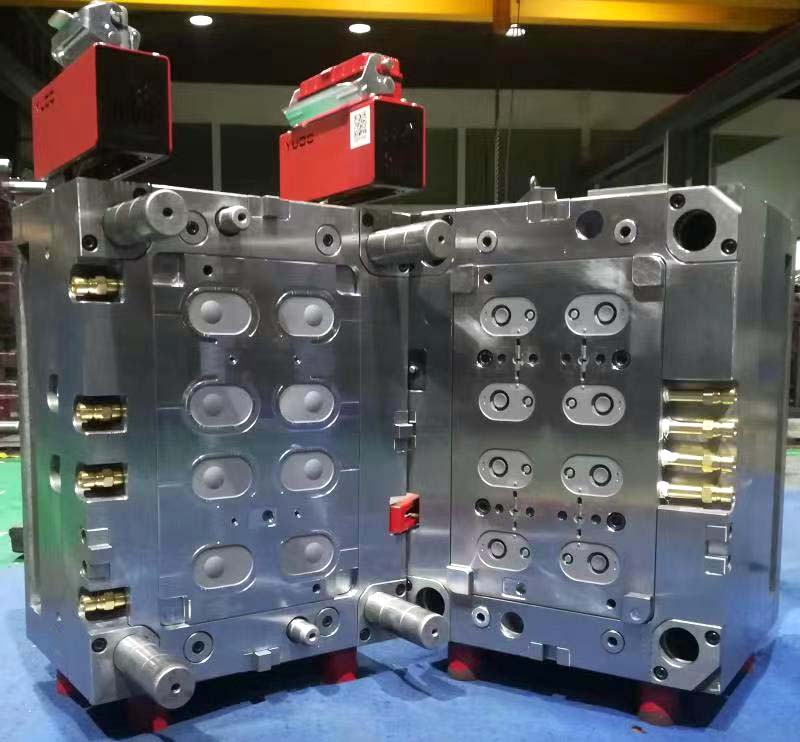

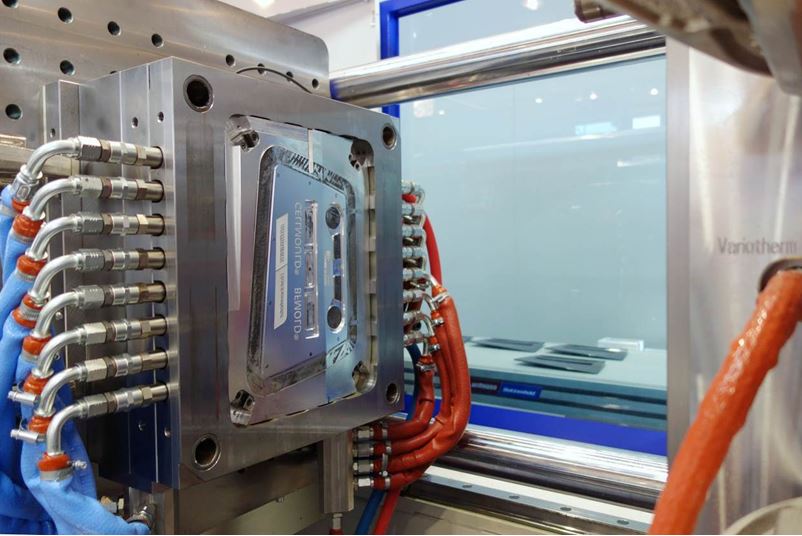

Chinese manufacturers leverage advanced machinery and automation to ensure high precision and efficient production in injection mold manufacturing. The use of state-of-the-art machinery allows for the creation of complex molds with high accuracy, meeting the stringent requirements of various industries.

Advanced tooling capabilities in China help in creating complex molds efficiently, enhancing production outcomes. Techniques such as Critical Path Planning (CPP) are utilized to align mold-making progress with the planned schedule, ensuring timely delivery. Additionally, the adoption of additive hybrid tooling, which combines traditional injection molding with 3D printing, is emerging as a trend to develop cycle times and improve efficiency.

Digital twin technology is also being utilized to simulate mold performance, significantly decreasing the number of physical prototypes needed during development. These innovations in tooling design and engineering lead to improved mold designs and enhanced production efficiency, making China as a leader in the injection molding industry.

Cost-Effective Solutions for Low Volume Production

For businesses seeking cost-effective solutions for low volume production, Chinese manufacturers offer significant advantages. The starting costs of custom injection molds can be as low as $1000+, making it accessible for smaller businesses and startups. This low-cost budget-friendly approach ensures that quality is not compromised despite the lower costs.

Chinese manufacturers welcome low volume production runs, which are ideal for producing between 1,000 to 50,000 parts. This flexibility is particularly beneficial for startups and small to medium businesses that need to balance cost with production needs. NICE Rapid, for instance, provides affordable tooling options specifically tailored for small to medium production runs, supporting budget-conscious projects.

Chinese manufacturers can produce up to 100,000 plastic parts prototype parts quickly using production-grade materials, facilitating rapid prototyping. Techniques like insert molding and over molding result in faster production cycles and lower manufacturing costs by minimizing the number of parts needed.

High Volume Production Capabilities

Chinese suppliers excel in managing high-volume production while maintaining flexibility in customization. Key points include:

- Over 7,000 injection molding facilities in China.

- Well-equipped to handle substantial mass production needs.

- Facilities support both low and high-volume production.

- Businesses can scale their operations as needed.

Producing large quantities without compromising on quality is a hallmark of Chinese manufacturers. They maintain the same level of precision and quality control across all production runs, ensuring that every part meets the highest standards. This capability makes China a reliable partner for businesses looking to manufacture high-quality products at scale.

Insert Molding and Overmolding Techniques

Insert molding and overmolding are specialized techniques that enhance the functionality and efficiency of injection molding. Insert molding involves:

- Encapsulating a prefabricated component with plastic

- Ensuring a strong bond and eliminating the need for assembly

- Using a variety of materials, including metals and ceramics

- Allowing for diverse applications

Two-shot injection molds enable the injection of multiple materials or colors simultaneously, reducing the need for additional assembly steps. Overmolding, on the other hand, applies a second layer of material to a part, improving its grip, wear resistance, and overall functionality.

These techniques can produce intricate parts in a single production step, resulting in a more efficient manufacturing process. Insert molding and overmolding techniques in China’s injection molding industry allow for the creation of complex and high-quality parts that meet diverse client needs. These methods are integral to producing advanced and reliable plastic components.

Lead Time and Efficiency in Production

Efficiency in production is a key strength of Chinese injection mold manufacturers. They excel in rapid production due to highly efficient processes, allowing for quick turnaround times:

- Highly efficient processes enable rapid production

- Quick turnaround times

- In some cases, mold production can be completed in as short as 10 days

- This speed caters to urgent project requirements

The strong supply chain in China enhances the efficiency of global deliveries, reducing lead times and ensuring timely shipment of products. This capability is crucial for businesses that need to meet tight deadlines and maintain a consistent supply of parts.

Chinese manufacturers are shifting towards intelligent manufacturing, incorporating AI and IoT for enhanced production efficiency and predictive maintenance. This shift not only improves the production process but also ensures high-quality products with minimal defects. Utilizing steel molds can further enhance production capacity, allowing for quicker turnaround times in manufactured goods.

Customer Testimonials and Case Studies

Larry Cole praised PTMS workmanship, stating it surpassed expectations on a time-sensitive project. Tim Latham expressed satisfaction with PTMS’s pricing, delivery, and overall quality. These testimonials highlight the reliability and quality of Chinese injection molding services.

Harwood Laskin stated that the details of the parts received from PTMS met all expectations and enabled further developed. Don Snoke commented on the ease of communication and smooth process he experienced while working with PTMS.

These case studies demonstrate the high level of professional and detail provided by Chinese manufacturers, ensuring customer satisfaction and successful project outcomes that achieve successful results.

Useful Resources for Injection Molding in China

Numerous resources are available for those new to injection molding or seeking to refine their processes. Guides on plastic materials, surface finishes, and troubleshooting common defects provide valuable information for beginner product designers and engineers. These resources help in making informed decisions about material selection and finishing services.

A comprehensive guide featuring over 27 common plastic materials is available to assist with material selection. Finishing services such as burnishing, painting, and plating are covered in detail. These resources ensure that businesses have access to all the necessary information to optimize their injection molding processes.

Recent Innovations in Injection Mold Technology

Recent advancements in injection molding technologies in China are significantly transforming the industry landscape. Innovations such as advanced surface engineering techniques are extending mold life significantly, with coatings that enhance wear resistance up to five times. These advancements are crucial for improving efficiency and reducing costs in the injection molding process.

Many injection molding companies in China utilize advanced technologies for testing and measurement during the quality control phase. These technologies ensure that every product meets the highest standards of quality and reliability, further solidifying China’s position as a leader in the injection molding industry.

Recommend the Leading Injection Mold Tooling Manufacturer in China – PTMS

PTMS is a leading manufacturer in China, known for producing top-quality plastic injection mold tooling as per customer requests. With many years of experience in plastic injection tooling, PTMS has built a reputation for excellence and reliability in the industry.

The company’s advanced machinery, including CNC machines, Wire Cutting Machines, and EDM machines, ensures precision and efficiency in machining production. PTMS’s commitment to quality and innovation makes it the go-to company for all molding needs, providing customers with top-notch services and products.

Summary

In summary, China’s injection molding industry offers a comprehensive range of services, from custom mold designs to high-volume production capabilities. The rigorous quality control measures and advanced tooling techniques ensure that every project meets the highest standards of precision and reliability.

Whether you are looking for cost-effective solutions for low volume production or need to scale up for high-volume manufacturing, Chinese manufacturers provide the expertise and resources to meet your needs. By leveraging these services, businesses can achieve top-quality products efficiently and cost-effectively.

Frequently Asked Questions about Injection Mould Tooling in China

Who is the best mold maker in China?

Richfields Plastic Ltd., Rilong Precision Mold Co., Ltd., and Shuangsheng Plastic Machinery Co., Ltd. are among the top mold makers in China, known for their quality and cost-effective solutions. Consider these companies for reliable injection molding services.

What are the benefits of using Chinese injection molding services?

Utilizing Chinese injection molding services significantly reduces production costs while ensuring high-quality products through advanced tooling techniques and stringent quality control measures. This combination makes them an advantageous choice for businesses seeking efficient manufacturing solutions.

How quickly can Chinese manufacturers produce injection molds?

Chinese manufacturers can produce injection molds in as quickly as 10 days, particularly for aluminum or soft steel tools, with low volume production typically completed within 3 to 30 days.

What customization options are available for plastic injection molds?

Extensive customization options for plastic injection molds include the selection of various plastic materials, personalized surface finishes, and consulting services to optimize choices based on material properties and intended applications.

How do Chinese manufacturers ensure quality control?

Chinese manufacturers ensure quality control through rigorous inspection processes, adherence to international standards, and sourcing components from reputable brands. This meticulous approach upholds high-quality standards throughout production.