Top-Quality Plastic Injection Molded Parts for High-Precision Industrial Manufacturing

Plastic injection molded parts play a central role in modern industrial manufacturing, powering industries that demand precision, consistency, and high-volume mass production. Whether used in automotive assemblies, industrial equipment, aerospace components, or consumer electronics, these parts offer unmatched versatility and performance. As global demand for durable and cost-efficient components continues to rise, manufacturers increasingly rely on plastic injection molded parts to achieve tight tolerances, stable quality, and scalable mass production.

Customers exploring injection molded parts often ask similar questions:

– How accurate can the parts be?

– Which materials are suitable for my application?

– What size or weight limitations exist?

– How do I ensure the parts meet my performance requirements?

This guide answers those questions and more, offering a clear, practical overview for buyers who want to understand how plastic injection molded parts support their projects.

Plastic injection molded parts are engineered to meet specific functional, structural, and aesthetic requirements. With advanced injection molding technologies, manufacturers can produce components ranging from micro-precision parts to large structural housings. The ability to customize materials, shapes, and performance characteristics makes plastic molded parts one of the most adaptable solutions in modern mass production.

What is Plastic Injection Molded Parts?

Plastic injection molded parts are components created by injecting molten plastic into a precisely machined mold cavity. Once cooled, the material solidifies into a stable, repeatable shape. This process is widely used because it supports high‑volume production, excellent dimensional accuracy, and a broad range of material options. For buyers evaluating manufacturing options, understanding how these parts are formed helps clarify why they are ideal for both simple and highly engineered applications.

Key Characteristics of Injection Molded Parts

– High repeatability across large production runs

– Ability to achieve tight tolerances for functional components

– Compatibility with engineering‑grade resins

– Support for complex geometries and fine details

– Stable mechanical performance across temperature and load conditions

– Cost‑efficient production once the mold is completed

Why Manufacturers Choose Plastic Injection Molded Parts?

– They offer excellent strength‑to‑weight ratios

– They can replace metal components in many applications

– They reduce assembly steps through integrated design features

– They support consistent quality across thousands or millions of units

– They allow customization in color, texture, and material properties

How the Plastic Injection Molding Process Works?

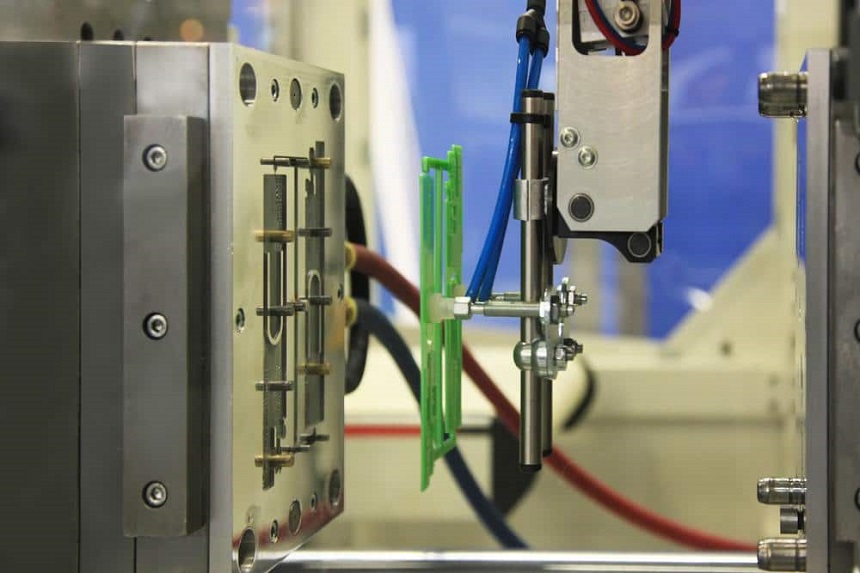

The injection molding process transforms raw plastic pellets into stable, high‑precision components through a controlled sequence of heating, injection, cooling, and ejection. Understanding this workflow helps buyers evaluate production feasibility, lead times, and quality expectations.

Melting and Material Preparation

The process begins with feeding plastic pellets into a heated barrel. As the screw rotates, friction and temperature gradually melt the material into a uniform molten state. Proper melting is essential because inconsistent viscosity can lead to defects such as warping, short shots, or surface blemishes. Material drying may also be required for resins like ABS, PC, or nylon to prevent moisture‑related issues.

Injection Into the Mold

Once the material reaches the correct viscosity, the screw pushes the molten plastic resin into the mold cavity under high pressure. This stage determines how well the material fills thin walls, sharp corners, and intricate features. Injection pressure, speed, and temperature must be carefully controlled to ensure dimensional accuracy and consistent part density.

Cooling and Solidification

After the mold is filled, the material begins to cool and solidify. Cooling time is one of the most influential factors in production efficiency. A well‑designed cooling system ensures uniform temperature distribution, preventing internal stress and deformation. The part must reach sufficient rigidity before ejection to maintain its final shape.

Ejection and Part Removal

Once cooled, the mold opens and ejector pins push the part out of the cavity. Proper ejection design prevents marks, deformation, or sticking. After removal, the part may undergo trimming, inspection, or secondary finishing depending on the application.

Design Considerations for Injection Molded Parts

Design is one of the most influential factors affecting the performance, manufacturability, and cost of plastic injection molded parts. A well‑designed part reduces defects, shortens cycle time, and ensures consistent quality across large production runs. Buyers who understand these principles can communicate more effectively with suppliers and avoid costly redesigns.

Wall Thickness Optimization

Uniform wall thickness is essential for preventing warpage, sink marks, and internal stress. When walls vary too much in thickness, the material cools at different rates, causing distortion. Most engineering plastics perform best with moderate, consistent wall thicknesses that balance strength and manufacturability. If thicker sections are unavoidable, gradual transitions or rib structures help maintain stability.

Draft Angles for Smooth Ejection

Draft angles allow the part to release smoothly from the mold during ejection. Without proper draft, parts may stick, deform, or require excessive force to remove. Even a small draft angle significantly improves production efficiency and reduces wear on the mold. Textured surfaces typically require additional draft to compensate for friction.

Rib and Boss Design

Ribs increase stiffness without adding excessive material. They are commonly used in housings, covers, and structural components to improve rigidity while keeping weight low. Bosses provide mounting points for screws or inserts. Proper rib‑to‑wall ratios, spacing, and fillet radii help prevent sink marks and ensure structural integrity.

Gate Placement and Flow Considerations

The gate is the entry point where molten plastic resin flows into the mold cavity. Its location affects surface appearance, weld line formation, and internal stress distribution. Strategic gate placement ensures balanced filling, reduces cosmetic defects, and improves mechanical performance. For complex parts, flow simulation helps identify the best gate configuration.

Tolerance and Dimensional Control

Injection molding supports tight tolerances, but achievable precision depends on material selection, part geometry, and mold quality. Critical features such as snap fits, alignment points, and sealing surfaces require careful tolerance planning. Overly tight tolerances may increase cost without improving performance, so balancing function and manufacturability is key.

Surface Finish and Aesthetic Requirements

Surface texture affects appearance, grip, and wear resistance. Options range from high‑gloss finishes to matte textures or functional patterns. The chosen finish influences mold polishing requirements and may affect cycle time. For consumer‑facing products, consistent surface quality is essential for brand perception.

Applications of Plastic Injection Molded Parts

Plastic injection molded parts are used across nearly every major industry because they offer a combination of precision, durability, and cost efficiency. Their adaptability makes them suitable for both high‑volume consumer products and highly engineered industrial components. Understanding where these parts are used helps buyers evaluate performance expectations and select the right materials and design features.

Automotive and Transportation

The automotive industry relies heavily on plastic molded parts to reduce weight, improve fuel efficiency, and enhance safety. Components such as interior panels, brackets, clips, housings, and under‑hood elements are commonly produced through injection molding. Engineering‑grade plastics withstand vibration, heat, and mechanical stress, making them ideal for demanding environments. Lightweight plastic injection molded parts also help manufacturers meet strict emissions and efficiency standards.

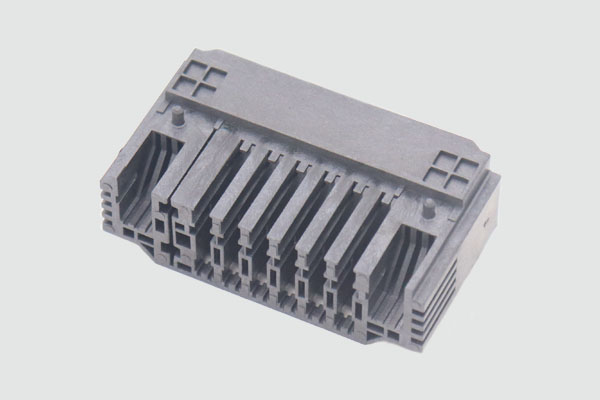

Industrial Machinery and Equipment

Industrial applications require components that can endure long‑term mechanical loads, exposure to chemicals, and continuous operation. Injection molded parts such as gears, bushings, covers, and structural supports are widely used in machinery. Materials like nylon, PBT, and reinforced polypropylene provide the strength and stability needed for industrial environments. The ability to integrate complex features into a single molded part also reduces assembly time and improves reliability.

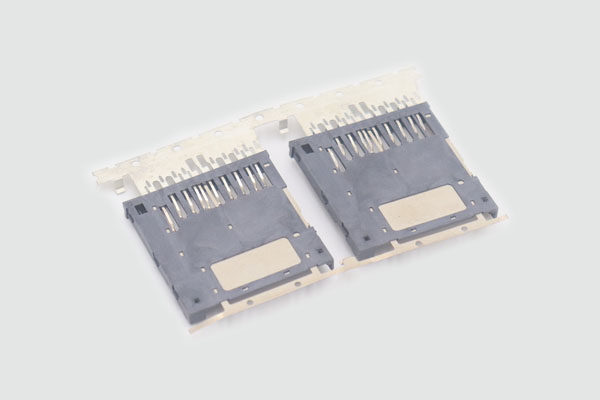

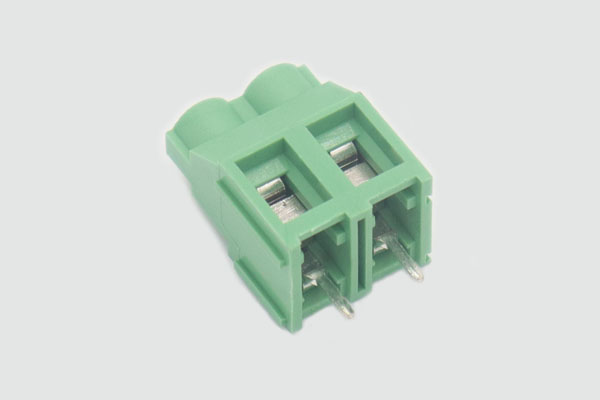

Consumer Electronics

Modern electronics depend on plastic molded parts for housings, connectors, buttons, and internal structural components. These parts must meet strict dimensional tolerances to ensure proper fit and function. Materials like ABS and polycarbonate offer excellent impact resistance and surface quality, making them ideal for devices that require both durability and aesthetic appeal. Injection molding supports high‑volume production, ensuring consistent quality across millions of units.

Medical and Healthcare

Medical devices require components that meet strict hygiene, safety, and regulatory standards. Injection molded parts are used in diagnostic equipment, surgical tools, housings, and disposable products. Materials such as medical‑grade polypropylene and polycarbonate offer biocompatibility, chemical resistance, and sterilization compatibility. The precision of injection molding ensures that critical components meet exact specifications.

Aerospace and Defense

Aerospace applications demand lightweight, high‑strength components that can withstand extreme temperatures and mechanical stress. High‑performance materials like PEEK and reinforced nylon are commonly used for brackets, housings, and structural elements. Injection molding allows manufacturers to produce complex geometries that reduce weight without compromising strength. This contributes to improved fuel efficiency and overall system performance.

Household and Consumer Goods

Everyday products such as kitchen tools, storage containers, appliance components, and personal care items rely on plastic molded parts. These applications prioritize durability, cost efficiency, and consistent quality. Injection molding supports a wide range of colors, textures, and finishes, allowing manufacturers to create products that are both functional and visually appealing.

Benefits of Using Plastic Injection Molded Parts

Plastic injection molded parts offer a combination of performance, efficiency, and scalability that few manufacturing methods can match. These advantages explain why industries ranging from automotive to aerospace rely heavily on injection molding for both simple and highly engineered components.

High Precision and Repeatability

One of the greatest strengths of injection molding is its ability to produce identical parts across large production runs. Once the mold is built, every cycle delivers consistent dimensions, surface quality, and structural integrity. This repeatability is essential for applications where components must fit together perfectly, such as mechanical assemblies, housings, and functional mechanisms. Precision also reduces the need for secondary machining, lowering overall production costs.

Cost Efficiency for Medium and High Volumes

Although mold fabrication requires an initial investment, the per‑unit cost decreases significantly as production volume increases. Injection molding supports rapid cycle times, automated operation, and minimal material waste. For manufacturers producing thousands or millions of units, this process offers unmatched cost efficiency. Even complex plastic molded parts become economically viable when produced at scale.

Support for Complex Geometries

Injection molding allows designers to incorporate intricate features directly into the part. Snap fits, hinges, undercuts, internal channels, and textured surfaces can all be molded in a single cycle. This reduces assembly steps and improves product reliability. The ability to integrate multiple functions into one molded component is a major advantage over traditional machining or fabrication methods.

Wide Range of Material Options

From flexible elastomers to high‑performance engineering plastics, injection molding supports an extensive selection of materials. This flexibility allows manufacturers to tailor parts for strength, heat resistance, chemical compatibility, or aesthetic requirements. Reinforced materials such as glass‑filled nylon provide metal‑like performance at a fraction of the weight.

Lightweight and Durable Performance

Plastic injection molded parts offer excellent strength‑to‑weight ratios, making them ideal for industries seeking to reduce mass without compromising durability. Automotive and aerospace manufacturers benefit from lighter components that improve fuel efficiency and reduce operational costs. Many plastics also resist corrosion, impact, and fatigue, extending product lifespan.

Excellent Surface Finish and Aesthetic Quality

Injection molding produces smooth, consistent surfaces that require little or no post‑processing. Textures, gloss levels, and patterns can be applied directly to the mold, allowing manufacturers to achieve premium aesthetics without additional finishing steps. This is especially valuable for consumer products and electronics where appearance influences user perception.

Scalability and Production Flexibility

Injection molding supports a wide range of part sizes, from micro‑components to large structural housings. Manufacturers can scale production quickly by adding cavities, optimizing cycle times, or using multi‑material injection molding techniques. This flexibility ensures that plastic injection molded parts can adapt to evolving market demands.

Comparison Table: Injection Molding vs Other Manufacturing Methods

Choosing the right industrial manufacturing method is essential for balancing cost, performance, and production speed. Injection molding is often compared with CNC machining and 3D printing. Each method has strengths, but injection molding stands out for high‑volume production and consistent quality.

| Manufacturing Method | Best For | Strengths | Limitations | Typical Cost Structure |

| Injection Molding | Medium to high‑volume production of plastic molded parts | Excellent repeatability, low per‑unit cost, supports complex geometries, wide material selection | Requires mold investment, longer initial lead time | High upfront mold cost, low per‑unit cost |

| CNC Machining | Low‑volume production, metal or high‑precision parts | Extremely accurate, supports metals, ideal for prototypes | High per‑unit cost, slower for large quantities, limited geometric freedom | No mold cost, high per‑unit machining cost |

| 3D Printing | Prototyping, custom parts, complex internal structures | Fast iteration, no tooling, supports intricate shapes | Limited material strength, slower for mass production, higher per‑unit cost | No tooling cost, moderate to high per‑unit cost |

What This Means for Buyers

– Injection molding is the most cost‑effective choice for large quantities.

– CNC machining is ideal for metal components or low‑volume precision parts.

– 3D printing is best for prototypes or highly customized designs.

For companies seeking scalable production of plastic injection molded parts, injection molding consistently delivers the best balance of cost, quality, and efficiency.

Case Study: Improving Product Reliability with Precision Injection Molded Parts

A mid‑sized industrial equipment manufacturer faced recurring issues with a machined metal component used in one of their core product lines. The part required tight tolerances, but machining inconsistencies caused frequent assembly problems and increased warranty claims. The company needed a solution that would improve dimensional stability, reduce weight, and lower production costs without compromising performance.

After evaluating several options, the engineering team decided to transition the component to a plastic injection molded design. By switching to a glass‑filled nylon material, they achieved the strength and stiffness required for the application while significantly reducing weight. The new design also integrated multiple features that previously required separate machining and assembly steps.

The results were immediate and measurable. Dimensional consistency improved across every production batch, reducing assembly time and eliminating the alignment issues that had plagued the previous design. The lighter component also contributed to improved energy efficiency in the final product. Most importantly, warranty claims related to this part dropped sharply, saving the company both time and money.

Client Testimonial

“We were surprised by how much performance improved after switching to injection molded parts. The consistency is far better than what we had with machined components, and the cost savings have been substantial. Our assembly team noticed the difference right away, and our customers have experienced fewer issues in the field. It was one of the best industrial manufacturing decisions we’ve made.”

This case demonstrates how plastic injection molded parts can enhance reliability, reduce costs, and streamline production. By choosing the right material and optimizing the design, manufacturers can unlock significant performance improvements.

Conclusion and Final Recommendations

Plastic injection molded parts remain one of the most reliable and cost‑effective solutions for modern industrial manufacturing. Their ability to deliver precision, durability, and scalability makes them essential across industries ranging from automotive and aerospace to consumer electronics and industrial machinery. With the right material selection, optimized design, and a well‑engineered mold, manufacturers can achieve exceptional performance while keeping production costs under control.

For buyers, understanding the fundamentals of injection molding helps ensure better communication with suppliers and more informed decision‑making. Factors such as wall thickness, draft angles, gate placement, and tolerance planning all influence the final quality of plastic molded parts. When these elements are aligned with the correct resin and production strategy, the result is a component that performs reliably throughout its lifecycle.

As global demand for lightweight, high‑strength, and cost‑efficient components continues to grow, injection molding remains the preferred method for producing consistent, high‑volume parts. Whether you need functional mechanical components, aesthetic housings, or specialized industrial parts, injection molding offers the flexibility and performance required to meet modern engineering challenges.

Why PTMS is the Right Partner for Your Injection Molded Parts?

If you are looking for a dependable supplier of plastic injection molded parts, PTMS stands out as one of the most experienced and trusted manufacturers in China. With advanced injection molding equipment, strict quality control, and deep expertise in engineering plastics, PTMS supports projects of all sizes and complexities. The company provides complete solutions from mold design to mass production, ensuring that every part meets your performance and reliability expectations.

PTMS is known for producing high‑precision plastic injection molded parts for automotive, industrial, medical, and consumer applications. Their team understands the importance of material selection, mold optimization, and dimensional accuracy, making them an ideal partner for companies seeking consistent quality and long‑term reliability.

If you want to learn more or request a quote, you can visit PTMS Plastic Injection Molded Parts page.

Authoritative References:

1). Frontiers in Materials

Injection molding is the most commonly used net‑shape manufacturing process.

Website: https://www.frontiersin.org/journals/materials

2). OSTI.GOV

A study on how the injection molding process affects material properties and energy consumption.

Website: https://www.osti.gov

3). MDPI

Injection molding is widely adopted in automotive, electronics, aerospace, and other industries.

Website: https://www.mdpi.com

4). Academia.edu

Research focusing on injection molding, cooling channel design, and mold structure optimization.

Website: https://www.academia.edu

5). Emerald Publishing

A systematic study on integrating injection mold design with additive manufacturing.

Website: https://www.emerald.com