5 Essentials for Your Best Plastic Injection Molding Quote

‘Well, I have the CAD drawing, what else could they possibly require?’ If this statement sounds familiar, this blog is for you—and no, the CAD drawing isn’t enough to get a good plastic injection molding quote.

A custom plastic injection molder could come up with a quote by looking at a CAD drawing (and in some instances, even a 2D, hand-drawn drawing can help). However, you’ll probably be adding unnecessary expense by not preparing a few necessary questions in advance to offer more information to your molder.

Here, we outline 5 essentials for your best injection molding quote:

1. What types of resins or polymers are needed for the part?

Do some research. By knowing the type of plastic material that will be best for your project, you’ll be giving the molder a reference point. A skilled molder will suggest the additives and/or resin they feel will offer the best outcome.

2. What is the complexity and size of the part?

Although injection molding is used to make many plastic parts, other molding processes may also be used. Generally, the injection molding process is ideal for making small, more complex parts. Using compression or injection molding, larger parts can be manufactured. Whole hollow objects such as bottles are manufactured with blow molding, extremely large parts are made with rotational molding.

3. What quantities are required?

Every injection mold is made differently. If you’re interested in a shorter production run or smaller quantities, using an aluminum mold will be your best bet. However, if your project requires huge quantities over an extended period of time, you should go for hardened steel mold. While the upfront cost of the latter is greater, it pays for itself down the line. Precision, large-volume molders like PTMS is expert in creating tools with hardened steel.

4. What is the part supposed to do?

Will the part be exposed to any environmental or chemical issues? The injection molder you’re working with must understand the part’s application. This would let the manufacturer know how sturdy should the part be and what the wear and tear will be over time. The information you offer will help your molder suggest the additives and/or resins needed for your project.

5. Are there samples or CAD drawings of the part to be quoted?

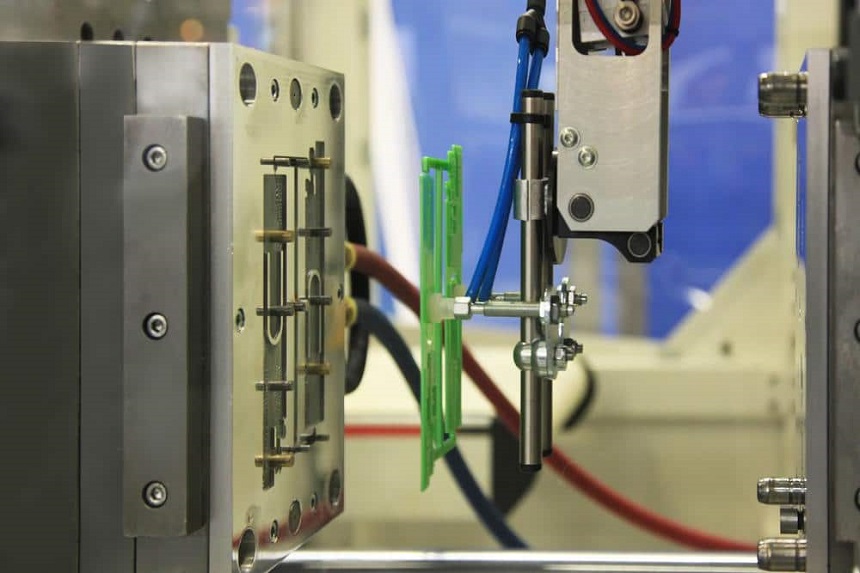

The molder should understand what you’re asking them to make. Otherwise, they’ll not be able to give you an accurate quote. By providing comprehensive dimensional drawings of the part, you can help them understand the complexity and size of the part. A prototype or sample can help the molder determine how to maximize the design for manufacturability.

Get one-stop service from mold design to products assembly with PTMS —the best injection mold maker in China

Being one of the best plastic injection molding companies in Shenzhen, China, PTMS specializes in the mass production of custom plastic parts. Our goal is to offer great quality custom plastic injection molding service and make value for customers.

Reach out to us now for an injection molding quote online!