Benefits of Using Plastic Injection Molding for Manufacturing with PTMS

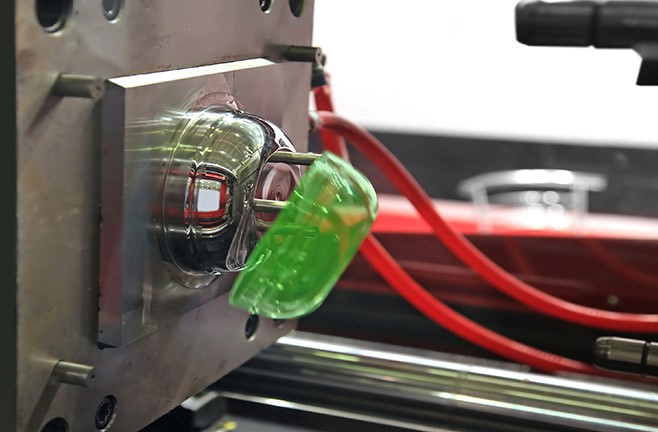

PTMS specializes in plastic injection molding for manufacturing, offering comprehensive solutions for industries such as automotive, medical devices, and consumer goods. In this blog, we’ll explore the benefits of using plastic injection molding for manufacturing with PTMS.

1. Cost Savings

One of the main benefits of plastic injection molding with PTMS is its cost-effectiveness. Once the initial tooling costs havHe been covered, the cost per part decreases significantly with larger production runs. This makes it an ideal process for high-volume manufacturing.

Additionally, plastic injection molding with PTMS allows for material waste reduction, as the excess plastic can be reused. This not only reduces material costs but also helps to minimize the impact on the environment.

2. Design Flexibility

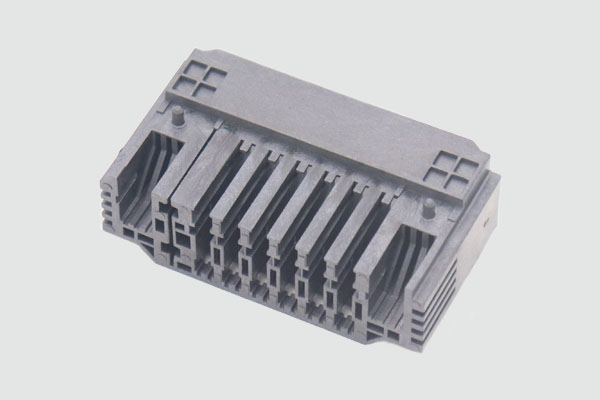

Another benefit of plastic injection molding with PTMS is its design flexibility. This process allows for the creation of complex geometries and internal features, which would be difficult or impossible to achieve with other manufacturing methods.

Furthermore, plastic injection molding with PTMS offers a wide range of materials to choose from, including thermoplastics, thermosets, and elastomers. Each material has its own unique properties, allowing for a tailored approach to design and manufacturing.

3. High-Quality Parts

Plastic injection molding with PTMS produces high-quality, precise injection parts with consistent tolerances. This is due to the high pressure and temperature used in the process, which ensures the plastic fills every detail of the mold cavity.

Additionally, plastic injection molding with PTMS offers a high level of repeatability, which is important for ensuring consistent quality across large production runs.

4. Faster Production Time

Plastic injection molding with PTMS offers faster production times than other manufacturing methods. This is because the process is highly automated, allowing for the production of large quantities of parts quickly and efficiently.

Additionally, plastic injection molding with PTMS allows for multiple cavities to be molded simultaneously, further reducing production time.

5. Reduced Labor Costs

Plastic injection molding with PTMS requires minimal labor, which reduces labor costs compared to other manufacturing methods. Once the initial tooling is complete, the process can be highly automated, requiring only a few operators to oversee production.

6. Versatility

Plastic injection molding with PTMS is a versatile manufacturing technique that can be used to create a wide range of products. This includes automotive parts, medical devices, consumer goods, and more. With its design flexibility and wide range of material options, plastic injection molding with PTMS can be customized to meet the needs of virtually any industry.

7. Environmentally Friendly

Finally, plastic injection molding with PTMS is an environmentally friendly manufacturing method. As mentioned earlier, the excess plastic can be reused, reducing material waste. Additionally, many plastic resins used in injection molding are recyclable, further reducing the environmental impact of the manufacturing process.

Conclusion

In summary, plastic injection molding with PTMS offers numerous benefits for manufacturing. From cost savings to design flexibility, high-quality parts, and reduced labor costs, this popular manufacturing technique is a go-to choose for many industries.

If you’re interested in learning more about how plastic injection molding with PTMS can benefit your business, contact us today. Our team of experts can help you choose the right approach for your product needs.