Cost-Effective Solutions for High-Volume Plastic Injection Molding: A Comprehensive Guide

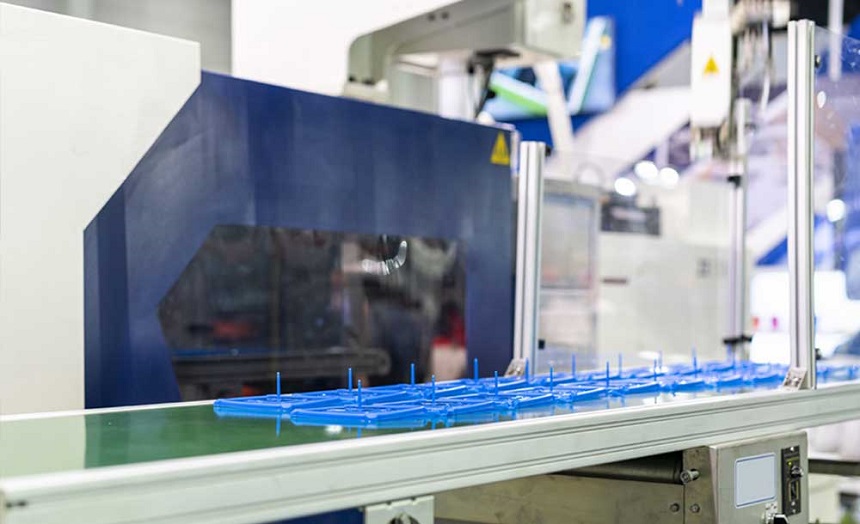

Plastic injection molding is a widely used manufacturing technique for producing high-volume plastic parts. However, the cost of production can quickly add up, making cost-effective solutions a top priority for manufacturers.

In this comprehensive guide, we’ll explore cost-effective solutions for high-volume plastic injection molding, including material selection, production optimization, and reducing waste.

1. Material Selection

Material selection is a critical factor in achieving cost-effective plastic injection molding production. By selecting the appropriate material for the product, material waste can be minimized, and production costs reduced. Additionally, material selection can impact production efficiency, cycle time, and part quality.

2. Production Optimization

Production optimization involves identifying and eliminating inefficiencies in the plastic injection molding process. This can include optimizing the production cycle time, reducing scrap and rework, and automating certain aspects of the process. By optimizing production, costs can be reduced without sacrificing quality.

3. Reducing Waste

Reducing waste is another important factor in achieving cost-effective plastic injection molding production. This can be achieved through material waste reduction, energy conservation, and reducing the use of non-recyclable materials. By reducing waste, the overall cost of production can be reduced, and the environmental impact minimized.

4. Standardization

Standardization is a key factor in achieving cost-effective high-volume plastic injection molding production. By standardizing processes and equipment, costs can be reduced through improved efficiency, reduced downtime, and easier maintenance.

5. Continuous Improvement

Continuous improvement is an important aspect of achieving cost-effective high-volume plastic injection molding production. By continuously seeking to improve processes and identify inefficiencies, costs can be further reduced, and production efficiency improved.

Conclusion

In summary, cost-effective solutions for high-volume plastic injection molding are essential for manufacturers looking to remain competitive in the market. Material selection, production optimization, reducing waste, standardization, and continuous improvement are all important factors in achieving cost-effective production. At PTMS Company, we specialize in plastic injection molding and can help you achieve cost-effective production without sacrificing quality. Contact us today to learn more.