Difference Between Thermoplastic and Thermoset Plastic

Thermoplastics and thermoset plastics are two different forms of polymer powders, which are differentiated depending on their behavior on reacting to the application of heat. Here, we explore the differences between thermoplastic and thermoset plastic:

Thermoplastics

These are resins that are solid at room temperature. But when heated, they become soft and ultimately become fluid due to crystal melting or from crossing the glass transition temperature.

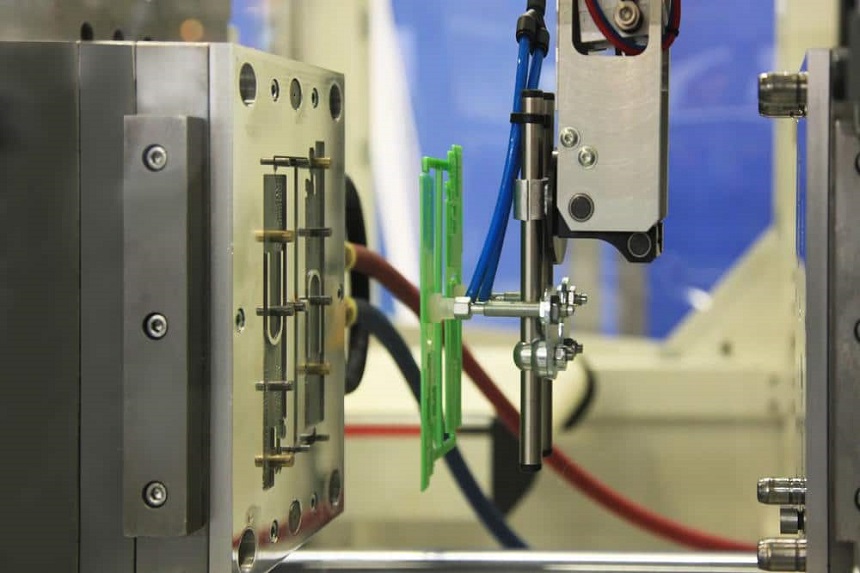

Processing thermoplastics doesn’t involve any chemical bonding and they can be poured into a mold to cool and solidify into a specific shape. It’s possible to remold, recycle, and reheat thermoplastics without changing their properties. Consequently, these materials are used in processes like injection molding, thermoforming, and extrusion.

Some common thermoplastics include PET (polyethylene terephthalate), PS (polystyrene), PP (polypropylene), PVC (polyvinylchloride), PC (polycarbonate), and PE (polyethylene), with each having different properties.

But generally, thermoplastics tend to resist shrinking whole providing good strength and elasticity. Thermoplastics are often used in applications like plastic bags for retail and industrial machine components. If exposed to high temperatures, they may also soften, deform, and lose some of their physical properties.

Benefits

Benefits

- Corrosion-resistant

- Resists chipping

- Can create both hardened and rubbery crystalline surfaces

- Enhanced anti-slip properties

- High impact resistance

- Good electrical insulation

- Resistant to detergents and chemicals

- Can be reshaped and recycled with little impact on properties

- High-quality aesthetic finish

- Good adherence to metals

Drawbacks

- More expensive than thermosetting polymers

- Not suited to every application because it softens when heated

Thermoset plastics

Also known as thermosetting polymers or thermosetting resin, thermoset plastics are usually liquid at room temperature and then harden with a chemical addition or when heated. They’re usually produced using RTM (resin transfer molding) and RIM (reaction injection molding) and form permanent chemical bonds during the process of curing. These chemical bonds between the monomer chains within the material hold the molecules together, changing the material’s texture and preventing it from returning to or melting to a liquid state.

When heated, thermoset plastics are set into a particular form, although overheating may cause them to degrade without entering a fluid phase.

Thermoset plastics are usually used in situations where heat plays an important role, like chemical processing equipment or electronic appliances/housings, as a result of their greater resistance and structural integrity to both chemicals and heat. Common thermosets can resist impact and deformation, and include phenolic, polyimide, and resins, which are typically used in composites.

Benefits

- Wide range of surface finishes and colors

- Water-resistant

- High strength-to-weight ratio

- Cheaper setup and tooling costs

- Low thermal conductivity

- Strong dimensional stability

- Corrosion-resistant

- Excellent heat resistance at high temperatures

- Brilliant electrical insulation properties

- Cheaper than components fabricated from metals

- Improved structural integrity through variable wall thicknesses

- Allows for flexible product designs

- Able to be molded with different tolerances

Cons

- Can’t be recycled

- Can’t be remolded or reshaped

PTMS is a high-quality plastic injection mold maker in China

PTMS is a professional injection mold maker, specializing in mold-making technology. With our experienced employees and advanced mold manufacturing equipment, we are quickly growing as a leading plastic injection molding company.

Reach out to us directly for more information!