Exploring the Innovation and Versatility of Plastic Injection Molding Parts

Plastic injection molding has emerged as a cornerstone of modern manufacturing, facilitating the production of a diverse range of precision injection components and intricate parts that power numerous industries worldwide. Let’s delve into the transformative impact of plastic injection molding parts, shedding light on their unparalleled versatility, innovation, and essential role in modern manufacturing.

Introduction to the Versatility of Plastic Injection Molding Parts

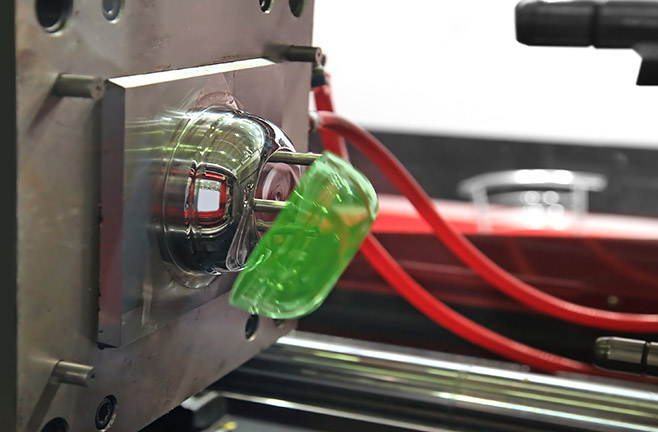

Plastic injection molding is an incredibly versatile technique for manufacturing plastic molded parts and components. It involves melting plastic pellets and injecting the molten material into a mold where it cools and solidifies, producing a final product that can be used in a wide variety of applications. This process is widely used by manufacturers to produce parts for industries such as automotive, medical, consumer goods, and more.

The versatility of plastic injection molding extends beyond just the manufacturing process. The properties of the plastic used in the injection molding process can be adjusted to create parts with specific characteristics. For example, plastics can be formulated to be strong and rigid, or flexible and pliable. This allows for the creation of parts that can withstand extreme temperatures, resist chemicals, and more.

Advantages of Plastic Injection Molding for Manufacturers and Consumers

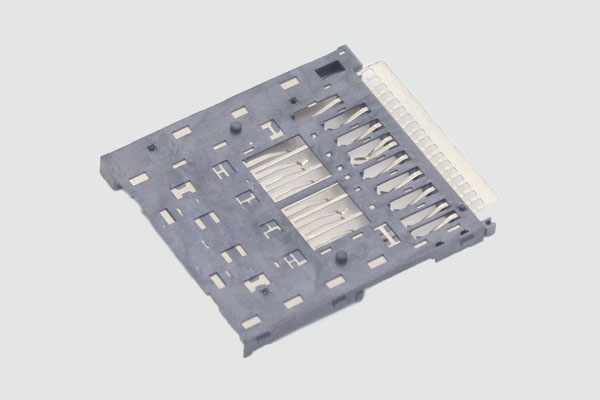

One of the key benefits of plastic injection molding is its adaptability. The technique allows for the production of complex and intricate designs, making it a popular choice for creating parts and components that require a high degree of precision and accuracy. Whether it’s an electronic component or a medical device, molded plastic parts can be created to meet specific requirements in terms of size, shape, and functionality.

Plastic injection molding is also a cost-effective manufacturing method, with the ability to produce large quantities of parts quickly and efficiently. This makes it an ideal method for mass production in industries such as automotive, where consistency and cost efficiency are of the utmost importance.

The process of plastic injection molding begins with the creation of a mold, which is typically made from steel. The mold is then mounted onto an injection molding machine, where plastic pellets are melted and injected into the injection mold. As the plastic cools and solidifies, it takes on the shape of the mold, resulting in a final product that is an exact replica of the mold.

Expanding Applications of Plastic Injection Molding in Various Industries

The innovation of plastic injection molding parts has been further expanded by the introduction of additives and materials that can enhance the properties of the final product. These parts can add additional strength or flexibility, improve heat resistance or flame retardancy, and increase durability.

Overall, plastic injection molding offers a wide range of benefits, from cost efficiency to versatility and the ability to create complex designs with precision and accuracy. The constantly evolving properties and capabilities of plastic materials have continued to expand the applications of plastic injection molding parts, making it an increasingly important manufacturing technique across a range of industries. As technology advances further, we can expect to see even more innovative uses for plastic injection molding parts in the future.

Unveiling the Power of Plastic Injection Molding Parts: A Tapestry of Precision and Adaptability

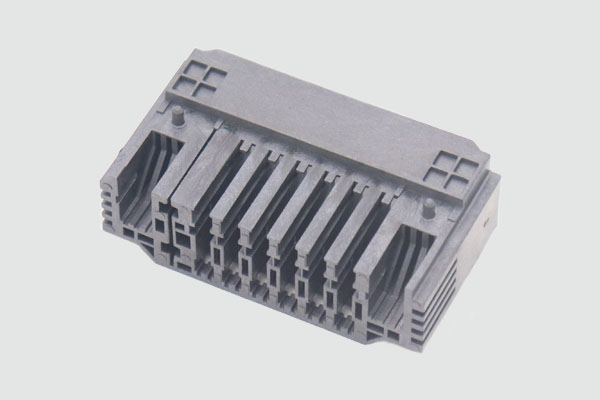

The world of plastic injection molding parts represents a diverse array of components, each meticulously crafted to serve unique functional and design requirements. From intricate automotive components and electronic enclosures to healthcare devices and consumer products, plastic molded parts embody the pinnacle of versatility and precision. Leveraging advanced mold design and cutting-edge materials, manufacturers produce an extensive range of components that adhere to the highest standards of quality, durability, and design intricacy, catering to a wide spectrum of industrial and consumer needs.

1. The Dynamic Landscape of Plastic Injection Molded Components: Fostering Innovation and Efficiency

Explore the wide-ranging applications and capabilities of plastic molded parts, showcasing their pivotal role in driving innovation and efficiency across diverse industries. With a strong emphasis on material properties and intricate design details, plastic molded components remain at the forefront of modern manufacturing, playing a vital role in the creation of durable, lightweight, and aesthetically appealing products that meet the evolving needs of the global market.

2. Pioneering the Future of Manufacturing Excellence: Embracing the Potential of Plastic Injection Molding

Delve into the intricate processes and advanced technologies that drive the evolution of plastic injection molding parts, underscoring its transformative impact on the contemporary manufacturing landscape. With an unwavering commitment to precision, quality, and design versatility, plastic injection molding continues to redefine the boundaries of possibility, setting the stage for a dynamic and progressive future in the realm of precision manufacturing.

Through its unwavering commitment to innovation, adaptability, and product excellence, the world of plastic injection molding parts continues to revolutionize the modern manufacturing landscape, embodying the spirit of versatility, durability, and design intricacy. As an integral component in the realm of modern production, plastic injection molding remains a vital force in driving manufacturing excellence and shaping the future of industrial and consumer product development.