PTMS in China – The Advantages of Plastic Injection Mold Tooling

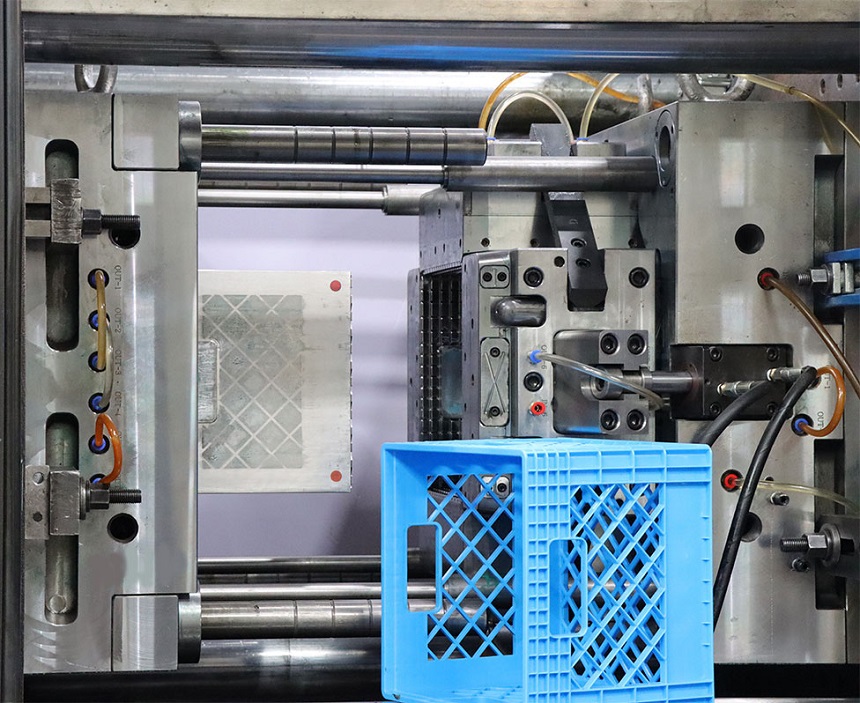

Plastic injection mold tooling plays a crucial role in the manufacturing industry, enabling the production of high-quality plastic products efficiently and consistently. As the injection molding industry continues to expand, companies around the world are increasingly turning to China for injection mold tooling solutions. In this article, we will explore the benefits of plastic injection mold tooling provided by PTMS in China, highlighting the reasons why more businesses are seeking their expertise.

1. Quality Assurance:

One of the primary concerns for manufacturers utilizing plastic injection molding is ensuring the highest quality of the finished products. PTMS in China is renowned for their commitment to quality and precision in every step of the injection mold tooling process. They employ advanced technology and top-notch facilities to design and manufacture molds with exceptional accuracy and consistency, ensuring the final products meet or exceed the strictest quality standards.

2. Cost-Effective Solutions:

Cost-effectiveness is another significant advantage of choosing PTMS for plastic injection tooling in China. The relatively lower labor and manufacturing costs in China allow PTMS to offer reasonable prices without compromising on quality. By partnering with PTMS for injection mold tooling, businesses can optimize their production costs, making their plastic products more affordable in the market.

3. Vast Experience and Expertise:

PTMS has extensive experience in the injection molding industry, making them a reliable partner for companies seeking plastic injection mold tooling solutions. They possess a deep understanding of the unique requirements and challenges associated with injection molding projects. Their team of skilled engineers and technicians has the expertise to develop customized injection molds tailored to meet specific product designs and production needs.

4. Efficient Project Management:

Efficient project management is vital for timely product development and delivery. PTMS is well-known for their streamlined project management approach, ensuring that all injection mold tooling projects are executed within the agreed timeline. They provide regular updates and maintain clear communication channels throughout the entire process, offering a hassle-free experience for their clients.

5. Cutting-Edge Technology:

PTMS keeps up with the rapid advancements in injection mold tooling technology, constantly integrating the latest innovations in their manufacturing processes. Their commitment to technology enhances the entire injection molding process, resulting in superior mold accuracy, reduced cycle times, and improved overall efficiency. This emphasis on staying at the forefront of technology makes PTMS a preferred choice for companies looking for advanced plastic injection mold tooling solutions.

Conclusion:

Plastic injection mold tooling from PTMS in China offers numerous benefits to manufacturers around the world. Their consistent focus on quality, cost-effectiveness, vast experience, efficient project management, and adoption of cutting-edge technology makes PTMS a trusted partner for companies seeking reliable and customized plastic injection mold tooling solutions. By collaborating with PTMS in China, businesses can enhance their competitive edge in the market by delivering high-quality plastic products efficiently and cost-effectively.