The Benefits of Entrusting Your Injection Molding to a Turnkey Manufacturer

A delicate balance of time and resources is required to mass produce a product with reasonable cost, on-time delivery, and consistent quality. While certain companies offer the lowest cost, they may lack the in-house capability to handle every facet of the production process. When it comes to choosing your manufacturing partner, you should go for a turnkey manufacturer that helps you with design, production, assembly, and delivery.

Here’s our injection molding company highlighting some benefits of entrusting your injection molding to a turnkey manufacturer.

Benefits

Invoice management

For a small manufacturer, collecting and managing payments can be a full-time job. Multiple suppliers translate to multiple invoices, which also require a system that must manage payments. With a turnkey partner by your side, you’ll be able to manage all incoming payments.

Easy communication

Of course, you don’t want to chase people over the phone and email trying to get updates from them, right? Trying to keep in touch with multiple partners isn’t easy — you may spend a lot of time doing so. So, what you need is clear communication, which is easy to understand. The communication shouldn’t just be timely, it should tell you where in the process you currently are. You can expect your turnkey partner to do the extra legwork, which can help you divert focus from daily operations so you can concentrate on tasks that matter more.

Inventory management

Keeping up with inventory management has become difficult, especially during the current global supply chain crisis. Some raw materials have become difficult to access, which may compel you to look for alternatives.

However, a turnkey partner can determine the location of finished goods, identify component storage, and can coordinate all incoming materials for production. Thus, you can focus on your final product.

Packaging and logistics

Coordinating packaging and logistics can be daunting. Your product may need either specialized or simple packaging before it’s shipped to a selling location or a holding distribution warehouse.

To professionally package and ship your new product, you’ll need experienced staff. If you’re confused as to what could be the best option, you’ll need some help. This is where a great turnkey partner can be of great assistance. They’ll not just define the available options but work with several top carriers to easily ship and distribute your products.

Specialized labeling

Labeling is important — it makes your product stand out from the competition by giving it a professional touch. This may include private labeling, part numbers for identification, or heat stamping/pad printing custom logos. Your turnkey partner would oversee the entire design work for the labeling process.

Secondary processes

If your product requires secondary processes such as tapping, drilling, or ultrasonic welding, your turnkey manufacturing partner may be able to make them part of the process. If you’re not sure whether or not a secondary process is required, your turnkey partner would guide you on the best course of action to maintain your product’s reliability and durability.

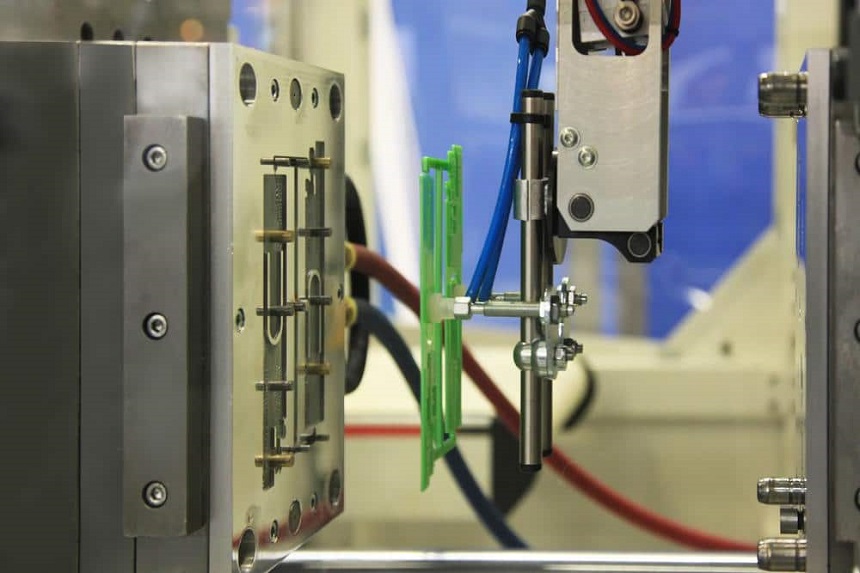

Tool manufacturing

Once your design is finalized and prototypes are sent for verification, it’s time to create the tool. You can either create permanent tools that can manufacture millions of parts or make temporary tools that can be used for low volume. Irrespective of the material and the case, your turnkey partner will create the dies in-house or send the work to a professional supplier. Don’t worry about who fully controls the tool creation.

Prototyping options

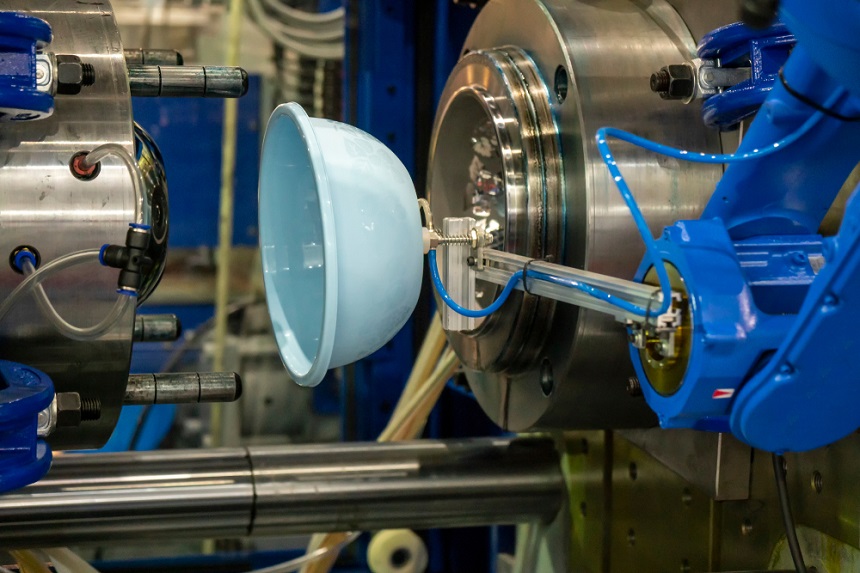

Over the last ten years, prototyping has reached new heights.

Previously, temporary tools and molds were made, which produced only a small number of parts. These tools and molds needed big investment, making the projects riskier. But thanks to a significant decline in the cost per machine, prototyping machines have become way too smaller.

Today, 3D printing can be done on desktop units, producing a number of resin filaments for tradeshows, design reviews, and prototypes. Numerous low-cost options are available to make plastic, metal, and hybrids for prototypes. To accommodate your needs, your new partner would provide a range of options.

Design ability and capability

There’s a starting point for every design — it may be a doodle on paper or just a random thought. To move forward, you must take your design to the 3D phase.

If you’re finding it difficult to do it yourself, partner with a turnkey manufacturer like PTMS. They have the capability to create 3D models. With an experienced turnkey manufacturer, you’ll not just keep your investment costs to a minimum but will also reduce the time required to go from a mere idea to a fully designed process.

Why partner with a plastic injection molding company in China?

The mold makers in China are some of the bests in the manufacturing industry. Since China is perceived as a powerhouse in the world of plastic, its mold manufacturers can offer extensive expertise and knowledge to your company in terms of plastic injection molding.

This means, you’ll have high-quality molds, and the quality will reflect in your plastic products. The overall efficiency of your manufacturing process won’t just affect your production, but it will have a considerable impact on your entire business operation.

Learning the injection molding process overnight isn’t possible because the process is extremely complex. While the internet definitely helps, nothing beats experience. This is one of the biggest advantages of mold makers in China, especially those who have been in the business of plastic injection molding for years. In addition, they’re always up to date with research and development within this domain.

Most mold manufacturers in China have access to advanced tools, proper training, and certifications, which increases their credibility by a significant margin. Thanks to resources like these, mold makers in China are always a step ahead of their competitors when it comes to plastic injection molding.

PTMS is your one-stop plastic injection molding company

PTMS is one of the leading injection molding manufacturers in China that offer full services including mold design, plastic injection tooling, plastic injection molding, metal parts, and product assembly. We’ve produced all kinds of top-notch custom plastic parts and metal parts at a reasonable price for different customers around the world.

Contact us now, we’d like to share over two decades of experience in every kind of injection molding mass production with our clients.