What Does ‘Green Molding’ Mean?

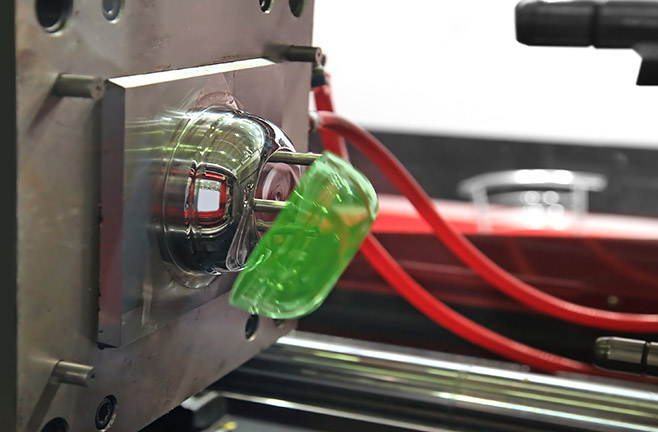

From general resin use to too much energy consumption and scrap, the injection molding process has raised some ecological concerns in the past. The alarm is neither unique nor surprising to injection molders or the industries they cater to.

Currently, manufacturers are consuming a lot of electricity and generating a lot of trash – and, at PTMS, so is the solution – don’t make trash, make electricity. As part of our energy reduction practices, along with our commitment to implementing green initiatives, we aim to reduce total waste and convert it into usable energy.

In this blog, we talk about the idea of ‘green molding.’

The issue of energy

Today, energy consumption in injection machines has dropped by at least 20%. Despite this improvement, the issue of energy consumption still exists.

During the process of plastic injection molding, total energy consumption is heavily influenced by the machine employed and the type of material. The choice of the type of machine – whether all-electric, hybrid, or hydraulic – has a considerable effect on the amount of energy consumed per kg of processed polymer.

The average SEC values for the machines discussed above are given below:

8 MJ/kg for all-electric machines

8 MJ/kg for all-electric machines

5 MJ/kg for hybrid machines

3 MJ/kg for hydraulic machines

While hydraulic machines provide better injection rates and greater clamp force, they consume the greatest amount of energy. While electric injection machines provide cleaner processing and high accuracy, they can’t achieve the same forces that hydraulic machines offer.

Generally, hybrid options offer the benefits of hydraulic force with the efficiency of electricity.

Making yourself familiar with the benefits and drawbacks afforded by every type of machine enables you to make a more informed decision as to which best suits your injection molding application.

Mitigating the environmental impact of plastic injection molding

There are tons of opportunities for facilitating sustainability and optimizing energy consumption throughout the injection molding process.

The EI’99 (Eco-Indicator 99) methodology is an LCA weighing method that explicitly focuses on the product design process. It offers calculable measures of environmental friendliness.

The EI’99 methodology highlights that a better focus on recycling the plastic resin from the process of injection molding would be a great step toward environmental sustainability.

Green initiatives at PTMS

At PTMS, we aim to put together sustainability initiatives in everything we do by:

Implementing recycling programs

Using non-toxic materials

Reducing energy usage

Minimizing waste and packaging use

We know that we have a key responsibility to society and Earth, and work hard to live up to that responsibility in every aspect of our business. Thus, we’ll continue to focus our efforts on working toward a green planet.

Get incredible mold project solutions with PTMS – the leading injection mold maker in China

PTMS has been a professional injection mold maker since 2002, offering customers of every size injection tooling for both low and high-volume plastic molded parts.

Give us a call now for more information!