15 Injection Molding Industry Terms You Should Know

If you’ve ever met your plastic injection molding expert, chances are, you’ve been blown away by the amount of industry-specific jargon they use. Similar to many industries, the field of plastic injection molding is quite specialized, which is why it isn’t surprising that it’s littered with hundreds of specific terms that may be clear to the industry experts but can leave you scratching your head.

So, before you meet your plastic injection molding expert again, familiarize yourself with the terms in this blog. This will help you get a better understanding of what they’re talking about.

1. Clamping force

It’s the force applied to the mold through the clamping mechanism to keep it closed. This opposes the pressure that melt exerts on the projected area of the runners and cavities.

2. Vent

In blow molds and during inflation, shallow channels allow air to escape from the mold by cutting into the parting line.

3. Gate

This is where the molten resin makes its way into the mold. In order to get the runner to the mold’s cavity, it flows through the gate.

4. Barrel

It’s part of the injection molding machine, and its main purpose is to feed plastic granules to the nozzle. When it’s heated, it melts the pellets into the resin.

5. Hopper

It’s a container that takes the shape of a cone and holds the plastic pellets to feed the machine. It’s used in extrusion, blow molding, and injection molding.

6. Viscosity

It’s a molten plastic material that’s resistant to flow.

7. Runner

It’s a canal for plastic, allowing it to travel from the injection molding machine.

8. Cavity

It’s the hollow space between the mold’s faces – these are eventually filled with plastic.

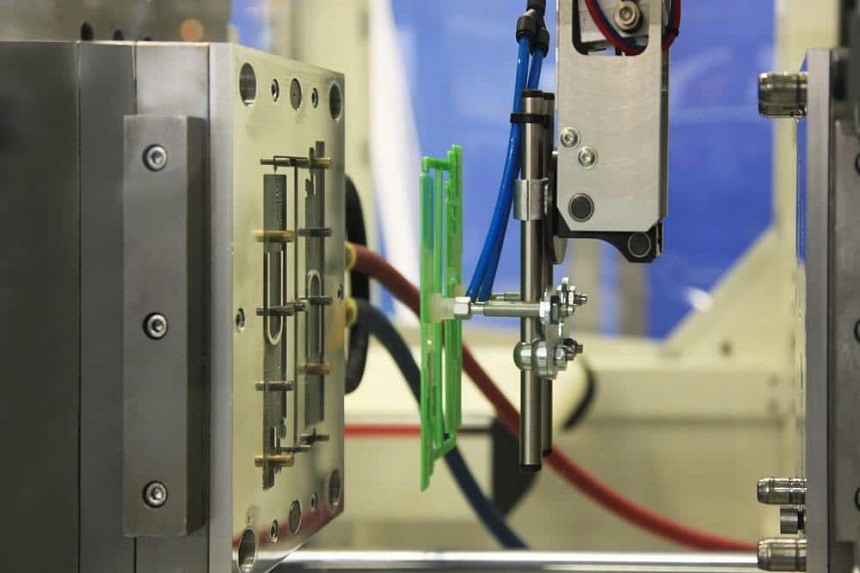

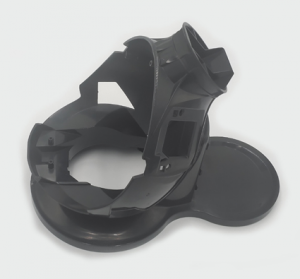

9. Mold

It’s a hollow container that shapes the injected molten plastic after it hardens and cools.

10. Colorant

It consists of pigments and raw dyes that are used to color plastics.

11. Additives

They are substances that are added to an essential polymer for improving its performance during end-use or processing.

12. Thermoset

It’s a plastic material which, once processed, can’t be melted again.

13. Thermoplastic

It’s a plastic material that can repeatedly be solidified by cooling and softened by heating.

14. Resin

It’s either synthetically made or naturally occurring. In essence, the thermoplastics industry uses this term interchangeably with polymer.

15. Polymer

This is either synthetically made or naturally occurring. When organic molecules are polymerized, thermoplastics are produced. These molecules are linked together within a reactor to form polymers – larger molecules.

Get custom plastic injection molding services from PTMS

As an ISO 9001-2008 certified plastic injection molding company, we’re quite strict with the product quality. We have 8 QC technicians for every shift in the shop who inspect the samples via inspection equipment.

Contact us now for more information about our plastic injection molding service!