How to Eliminate Injection Molding Weld Lines?

The main aim of every manufacturer is to have the process, machines, and quality assurance in place to eliminate, or at least reduce, the flaws from final products and parts.

Here, we look at weld lines – one of the most common part defects that may emerge from injection molding. Read on to find out what weld line defects are and how to eliminate them!

What are weld line defects?

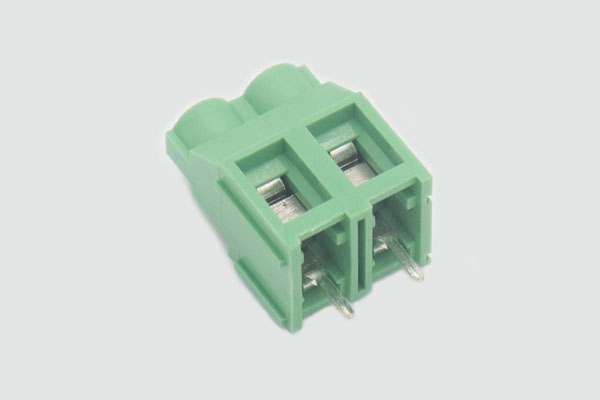

Also referred to as knit lines, weld line defects occur when the injected plastic comes in contact with a mold. The polymer resin is forced into a mold, which allows it to flow through every part of the mold. In areas where the plastic moves around a solidified piece of the mold, from a circle to forming intricate shapes like squares or rings, at least two fronts of molten plastic reunite into one piece – well, they’re supposed to.

When they don’t ‘knit’ completely back together, this defect forms.

How to eliminate injection molding weld lines?

Adjust the molding conditions

By adjusting the molding conditions, you can eliminate weld lines in plastic injection molding. The conditions are injection pressure, injection speed, and temperature.

If the injection pressure and speed are low, and if the melt temperature is low, you’ll get a more pronounced weld line.

However, increasing these conditions can help you eliminate the weld lines.

Alter the mold design

Increase the size of the gate and runners to alter the mold design. Don’t forget to eliminate entrapped air in the weld line injection molding; otherwise, it’ll create unfilled portions in your part design, causing more weakening. Place a vent in the weld line area to remove the entrapped air.

Changing the gate design is another way to alter the mold design. This will either ensure the weld line injection molding form closer to the gate at a high temperature and under high packing pressure or completely eliminate them.

Alter the part design

Increase the wall thickness to alter the part design. This will ensure that there’s a higher melt temperature and help to facilitate pressure transmission. Thanks to these thickening part walls, you’ll be able to slow down the resin cooling speed. This allows the resin more time to spread to the uncovered part before it cools and solidifies.

However, don’t make the walls of the parts too thick. If you do, you’ll end up having sink marks.

You can also reduce the part thickness ratio. The liquid will cover a broader range faster with a lighter flow, closing up the weld line.

You can also adjust the gate position and dimension. Don’t keep the knit-causing part too close to the edge of your design. If you keep it too close to the edge, it may break off easily.

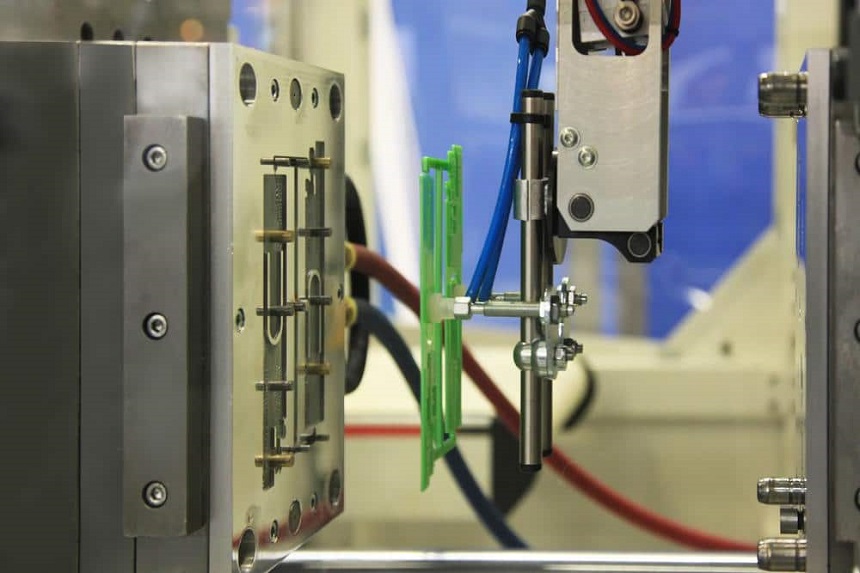

PTMS has been offering top-notch injection molding services since 2002

As a plastic injection molding manufacturer, PTMS likes to share over two decades of experience in making different kinds of molds. We also offer injection molding mass production.

Get in touch with us now for an instant injection molding quote!