Key Trends in Manufacturing Plastic Products in 2022

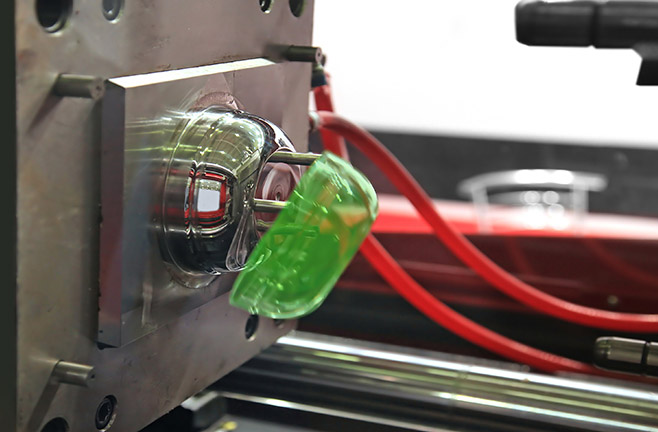

Plastic injection molding is a popular manufacturing process, lauded for producing plastic parts in bulk. This fast-moving method has been around for years.

With the evolution of technology and as consumers become more specific about the features they want in their products, it’s not wrong to say that we’re seeing a number of emerging trends.

As one of the leading plastic injection molding companies, we discuss some keys trends in manufacturing plastic products:

Rotational molding

In the rotational molding space, two trends that stuck out most to us in 2021 were continuing acquisitions/market consolidation and labor issues that stagnated production at certain molding shops, prolonged lead time, and drove supply chain challenges. While 2022 will see a lot more labor shortages, it’s expected to drive an increase in automation — something the market has been looking into for years. With new polyethylene capacity coming online from various producers in the US, we hope that this year will bring some relief (in terms of supply chain) to the rotational molding market.

Electronics and electrical

The reshoring of computer equipment and electronics injection molding tools was one of the biggest trends in the electronics and electrical market in 2021. In 2022, we expect that labor shortage will still be an issue, as it has been for years, and consequently, the need for robotic manufacturing and robotics will increase considerably. We also anticipate that there will be a high demand and a lot of movement toward sustainable electronics and electrical materials as OEMs buckle down on meeting their sustainability and carbon-neutral commitments.

Wire and cable

In 2021, we witnessed one of the most impactful changes in wire and cable. The telecommunications sector grew significantly, including high-speed internet access, which is crucial for both residential and commercial infrastructures.

In 2021, we witnessed one of the most impactful changes in wire and cable. The telecommunications sector grew significantly, including high-speed internet access, which is crucial for both residential and commercial infrastructures.

The main driver of this growth was a need to close the digital divide in the US, which drove a need for antennas, amplifiers, splice kits, connectors, conduits, and fiber optic cables. We expect the telecommunications sector to grow in 2022 as well. In fact, this year will bring a greater push by OEMs for more sustainable material options. The need for fiber-density cables will also increase, which use less energy and fewer materials to manufacture.

Packaging

In 2021, we saw converters and brands make strides in designing consumer packaging solutions that place a higher emphasis on consumer end-use and get rid of unnecessary packaging. The momentum will continue to build in 2022 and we expect to see packaging brands emphasize innovative solutions that lead to a more circular economy. We also believe that in different parts of the planet, including the US, we’ll see Extended Producer Responsibility schemes propel.

3D printing

In 2021, the two trends that made the most impact in the 3D printing market were machine accessibility and speed. The prices of machines are coming down and their speeds are around ten times faster than previous versions. This has allowed organizations to embrace 3D printing applications for manufacturing.

We also witnessed a great deal of M&A activity in the past year, and we’ll continue to see this market consolidation continue in 2022 as organizations work to amplify their offerings and, in certain cases, buy 3D printing companies to bring those services in-house. Gone are the days when a 3D printing company could make or do just a single thing. There’s a shift taking place toward full-service offerings — everything from resources to equipment and materials.

Automotive

We were quite astonished by the degree of disruption the automotive industry saw in 2021. From limited material availability, chip shortages to supply chain issues, it was a lot for tiers and OEMs to deal with. While there will still be supply chain issues in 2022 and 2023, we’ll see new capacity coming online in 2022, which will make existing challenges a lot more manageable.

2022 will be a big year for EVs (electric vehicles) development and plastics will play a critical role in manufacturing those vehicles — everything from interior and exterior application development to battery components and under-the-hood wiring.

There will also be a push to figure out what happens to those components and materials once the EV completes its life. OEMs are setting aggressive goals, with some looking to use as many sustainable materials as they can.

Sustainability

Sustainability isn’t just a trend — it’s intrinsic to the future and purpose of our industry.

In 2021, we saw questions being raised on the increasing plastic waste. These conversations will get louder until more scalable, efficient infrastructure solutions are introduced. This year, we expect to see more movement on regulations and policies by industry groups and governmental agencies to inspire products that use compostable or recycled plastics at the beginning of life and ensure a better end-of-life story.

To build upon the progress we’ve made so far, better collaboration is needed with every stakeholder across the sustainable value chain.

Healthcare

2021 has been a big year for healthcare. While there have been a ton of advancements in this market, there are two main trends that have stood out. The first is the increased investment and market consolidation in innovation and tech within the medical device and healthcare space.

The second is the inclination toward robotic surgery as patients begin to come back to healthcare facilities for elective and non-critical procedures. This year, we anticipate greater reshoring for medical device OEMs and continued supply chain shortages. We may also see a bigger push for more sustainable materials in healthcare, specifically in packaging, research into new vaccine delivery methods, digitally linked patient monitoring devices, and growth in areas like chronic illness care — all of which offer opportunities for plastic materials to shine.

PTMS — the best plastic injection molding manufacturer — offers custom plastic injection molding using 100% brand new materials

With years of experience in plastic injection molding, PTMS has been offering customers top-of-the-line custom plastic injection molding mass production for almost two decades.

Get in touch with us now to get an injection molding quote from our plastic injection molding company!