The Benefits of Small Batch Injection Molding

Our company specializes in many different small batch injection molding mass productions in the past 20 years. In the fact, many plastic parts are made by injection molding technology, so the small injection molding is very popular in recently years. But do you know why? Because many benefits for this molding. This time we will discuss the issue and give some useful advice.

1. Much lower cost. The cos of injection is very lower than other tooling, such as casting, CNC, stamping and etc. So many products are made of molding parts, it can cut down the total cost, make sure good price for people in the life. Easy for form. Plastic resin is very easy to form by mold, good for mass production. 2. Easy to assembly. The parts made by small batch injection molding is not heavy, very easy to make the assembly. 90% of the products are made by many different plastic parts. Easy to use. in the fact, the plastic products are easy to use, easy for clean, easy for modify if some broken.

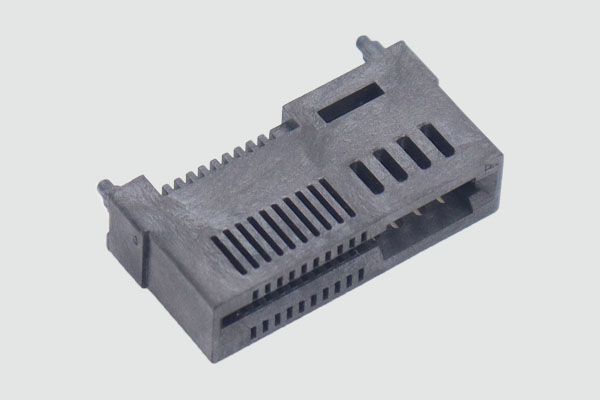

Here is a complex electronic connector and made by small plastic injection, resin is Nylon+30% GF, not all can make such parts, just a few professional shops can do it well, it’s very strict for the mold. PTMS focus on many kinds of complex connector for many years, because we have much experience in small batch injection molding mass production since 2002, the smallest size we can make is 2mmx5mmx2mm, the small light is 0.35g, accuracy is +/-0.001mm, you can know our ability, our team will help you with the project solution all the time!