What Products Can Be Made Using Injection Molding?

There are many different types of products that can be produced using injection molding. These include medical, household and telecommunications products. You will need to make sure that you get a good understanding of the type of product that you need before you hire someone to do the work for you.

You can make the following products using the injection molding process.

Toys

Injection molding is a common and reliable method of bringing toy ideas to life. It offers excellent precision and allows toys to be produced quickly. The process works with many different materials, which gives manufacturers the ability to make a variety of toys, including computer screens, brake and engine parts, and plastic bottle caps.

Injection molded toys are also very affordable. Toys that have been produced through this process often have sharp corners and frequent flat areas. This ensures that the toys are sturdy and function properly.

Toys that have been molded through the injection molding process are durable, which is ideal for children. They also come with a professional finish.

Household Products

Household items made through injection molding include containers, toys, and health care supplies. These plastic products are often made from engineered resins that offer a great deal of versatility. They also come in many different colors and custom shapes.

Injection molding is a technique used to create a wide variety of products including household products. It is a cost-effective way to produce a wide range of shapes and sizes, while providing a durable and easy-to-clean product. Plastic injection molded parts are also recyclable.

Plastic products are particularly well suited for sanitary environments, such as kitchens. This type of material also allows for easy cleaning, which makes them appealing to many consumers.

Medical Industry

Plastic injection molding is a versatile process that allows you to create medical products of different kinds. It is a cost-effective solution for creating medical equipment. Medical injection molds are used to make components for surgical and drug delivery equipment, as well as personal protection equipment.

A large amount of equipment in the medical field is made from plastic. These parts must be durable, sanitary, and strong to perform their intended function. They also need to be able to withstand the harshest environments.

As a result, the plastic materials that are used in the medical industry must be capable of surviving a wide range of conditions. Some common plastics include polypropylene, polycarbonate, and silicone.

Telecommunications Industry

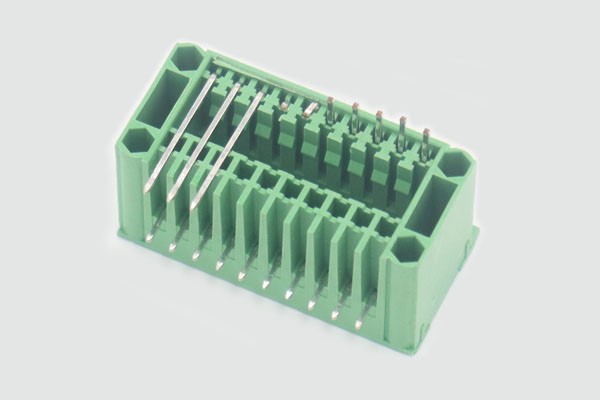

Telecommunications is an industry that involves a variety of electronics and fiber optic cables. This includes smart phone devices, mobile broadband and even wireless Internet.

The industry has undergone a huge shift over the past two decades. There has been an increased need for high-speed data connectivity. This is linked to the increasing number of mobile subscribers. Additionally, there has been an increased need for value-added managed services.

Many of these services require specialized parts, including injection molding. Precision injection molding can produce high-quality, durable materials that are also lower in cost.

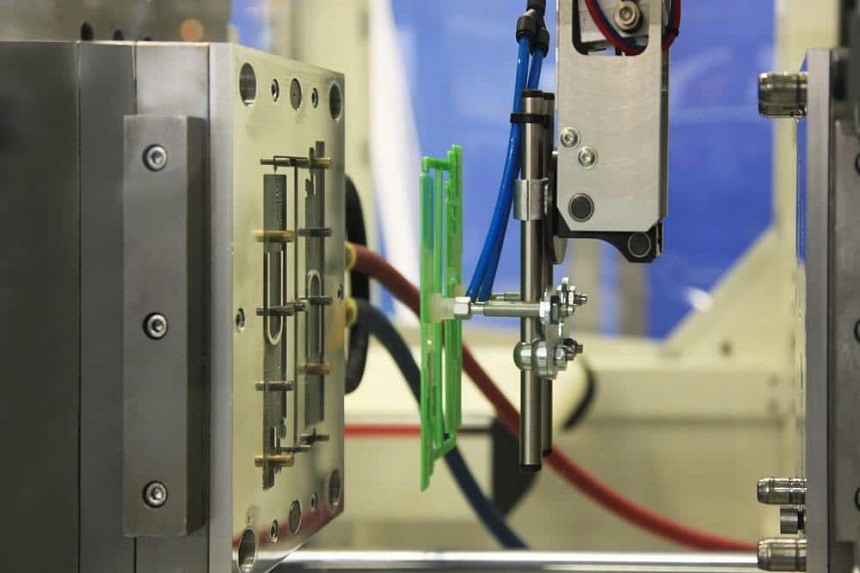

To produce these components, a plastic injection molding company must have the right equipment and expertise. They must also be able to adapt quickly to their clients’ needs.

Polycarbonate

Polycarbonate is a material which can be molded into a wide variety of products. Its unique properties include transparency, impact resistance and high strength. These characteristics make it ideal for use in many industries.

Injection molding is the process used to create polycarbonate parts. It is fast, efficient and inexpensive. This manufacturing technique makes efficient use of raw materials, while ensuring tight tolerances.

Choosing a good injection machine is a critical step in the process. Most modern machines feature gradual temperature rises and barrel heating zones. The resulting cycle time and productivity are both improved.

Polycarbonate can be made using a number of techniques, but only injection molding offers consistent results. It is also the only method that guarantees the production of large volumes of polycarbonate.

Acrylic

Acrylic can be used to make many different types of products, including enclosures for exhibits, windows, display cases, windows on golf carts, and food containers. Acrylic is usually used in combination with other plastics to create stronger, higher quality products.

Injection molding is the process of injecting acrylic into an injection mold. This method is commonly used to produce large volumes of high-quality acrylic parts.

However, it can be a complicated process. You will need to consider the strength and heat resistance of the acrylic material. Also, you need to ensure that the area you are working in is well ventilated. During the process, it is important to monitor the flow of molten material after injection.

The Bottom Line

At the end of the day, there are several products you can make using the injection molding process. These include acrylic, polycarbonate, telecommunications items, medical items, household products, and toys. If you want to get plastic injection molding work done perfectly, contact PTMS Tooling & Molding NOW!