How To Calculate Custom Injection Molding Cost?

How to calculate custom injection molding cost? It’s a rather difficult question for the exporters and importers, because the cost is based on many different factors. As a professional company, we would like to produce high quality parts with reasonable custom injection molding cost, the importers can’t accept the products with high price.

What’s the factor affect the cost? Let us tell you more details, being a factory, we think it should include some factors, such as the cost of plastic resin, the part weight, injection machine cost, labor cost, and other cost. Normally the common materials include ABS, PC, PC+ABS, SAN, HIPS, GPPS, HDPE, LDPE, PP, PE. ABS is used for the case for outside, PC is used for inner parts. All the cost of materials are increased recently, it’s 45 USD per 50kg for ABS in 2010 year, but now it’s 79USD per 50kg for ABS in 2021 year. Besides, the labor cost is up and up year by year, the rent cost is also increased year by year, other costs is also increased right now.

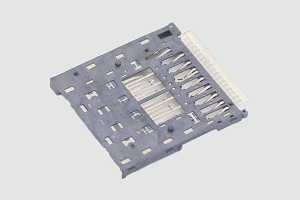

Where to get reasonable custom injection molding cost? Just contact PTMS, one professional injection molding factory in Shenzhen, China. This company can provide you reasonable cost for the mass production. Here is a precision connector, it’s made by nylon and glass fiber, used for internal parts, hardware in mold in mass production, this part is widely used in electronic products. Do you want reasonable injection molding cost? Welcome to contact us.